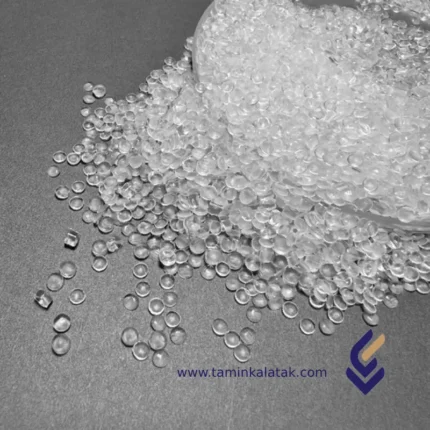

ThermoPlastic Elastomer

Thermoplastic elastomers (TPE) are a unique combination of properties of both plastics and rubber. These materials have both the flexibility and elasticity of rubber and the thermal processability of plastics. This unique combination has made TPEs one of the most popular materials in various industries.

TPE are typically composed of two or more polymers linked together in a block or branched structure. This structure allows them to have both elastomeric and thermoplastic properties.

Applications of TPEs

TPEs are used in a variety of industries due to their unique properties, including:

Automotive industry: Interior parts of cars such as gear levers, seat covers, and under-hood parts.

Medical industry: Medical gloves, medical tubing, and other medical equipment.

Sports industry: Athletic shoes, balls, and other sports equipment.

Packaging: Flexible packaging, airbags, and protective packaging.

Home use: Home appliances, toys, and other consumer products.

Electronic industry: Protective coverings for cables and electronic components.

ThermoPlastic Elastomer

| Products | Grade | Elongation at break | Density (g/mm3) | Tensile strength | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|---|

| ThermoPlastic Elastomer | 200 – 375% | 1.15 – 1.25 g/cm³ | 10 – 45 MPa | ||||

| ThermoPlastic Elastomer |

| Applications | , , , |

|---|

Related products

Acrylonitrile Styrene Acrylate (ASA)

Acrylonitrile Styrene Acrylate structureASA is typically formed by grafting acrylonitrile and styrene onto an acrylic ester elastomer backbone. The acrylic ester phase provides the material with flexibility and impact resistance, while the acrylonitrile and styrene phases contribute to rigidity, chemical resistance, and surface finish.

Acrylonitrile Styrene Acrylate propertiesAcrylonitrile-Styrene-Acrylate (ASA) polymer exhibits a combination of properties that make it well-suited for outdoor and demanding applications. Acrylonitrile Styrene Acrylate (ASA) polymer is a thermoplastic known for its excellent weather resistance, high impact strength, and UV stability, making it ideal for outdoor applications. It combines the toughness of acrylonitrile, the rigidity of styrene, and the weather-resistant properties of acrylic ester, resulting in a material that maintains its color, gloss, and mechanical integrity even under prolonged exposure to sunlight and harsh environmental conditions. ASA is resistant to chemicals, heat, and environmental stress cracking, and it exhibits good processability, enabling it to be molded into complex shapes. Its durability and aesthetic qualities make it suitable for use in automotive parts, outdoor furniture, and building materials.

ApplicationAutomotive Industry

- Exterior Components: Used for manufacturing exterior parts like side view mirrors, radiator grilles, and trims due to its resistance to UV radiation and harsh weather conditions.

- Interior Components: Employed in dashboards, panels, and other interior parts requiring durability and aesthetic appeal.

- Roofing and Cladding: ASA is used in roofing sheets, siding, and cladding materials for its resistance to fading and cracking when exposed to sunlight.

- Windows and Doors: Frames and profiles made of ASA are durable and maintain their color over time.

- Casing and Enclosures: ASA is used in the production of enclosures for electronic devices, electrical components, and appliances due to its impact resistance and aesthetic surface finish.

- Connectors and Insulators: The polymer is valued for its insulating properties and stability.

- Outdoor Furniture: Widely used for chairs, tables, and other outdoor furniture because it retains color and strength under prolonged exposure to sunlight and rain.

- Household Items: Utilized in kitchen appliances, vacuum cleaners, and other durable goods.

- Filament Material: ASA is a popular material for 3D printing, especially for outdoor applications, as it offers better UV resistance compared to ABS.

Advantages

- High impact strength

- Good Processability

- Weather Resistance

- Color and Gloss Retention

- Durability

Disadvantages

- Limited High-Temperature Resistance

- Flammability

- Lower Strength Compared to Metals

- Environmental Impact

Expandable PolyStyrene (EPS)

Expanded PolyStyrene structureThe structure of Expanded Polystyrene (EPS) consists of tiny, closed-cell foam beads made of polystyrene. These beads are expanded using heat, causing them to expand up to 50 times their original size. Also each bead contains air pockets.

Expanded PolyStyrene propertiesExpanded polystyrene (EPS) is found to be the most commonly used polymer core. This is because it is lightweight, resistant to moisture and also it has a long life. Studies have concluded that softening of EPS starts when exposed to temperatures ranging from 100°C to 120°C. In the process of flashovers, EPS melted about 160°C and then vaporized, producing poisonous gases at a temperature of 275°C. EPS is an inert, low density hydrocarbon-derived thermoplastic which contains several spherical beads with 2 percent polystyrene and 98 percent air

Expanded PolyStyrene applicationsBuilding and Construction-EPS is widely used in the building and construction industry due to its insulation properties. It can be used:

- As insulated panel systems for facades, walls, roofs and floors in buildings.

- As flotation material in the construction of marinas and pontoons.

- As a lightweight fill in road and railway construction.

- in the packaging of foodstuffs such as seafood, fruit, and vegetables.

- to produce food service containers like drink cups, food trays, and clamshell containers.

expanded polystyrene advantages

- lightweight

- water-resistant

- easily manufactured

- Energy Efficient

- high Durability and Longevity

expanded polystyrene disadvantages

- vulnerability to compression

- limited fire resistance

- non-biodegradable

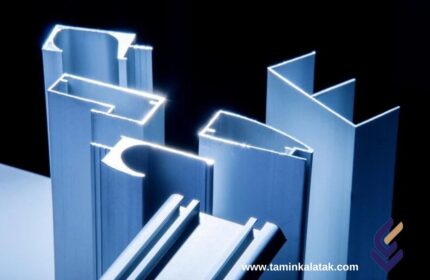

Extrusion

Hot extrusionHot extrusion is a hot working process, which means it is done above the material’s recrystallization temperature to keep the material from work hardening and to make it easier to push the material through the die. Most hot extrusions are done on horizontal hydraulic presses that range from 230 to 11,000 metric tons . Pressures range from 30 to 700 MPa , therefore lubrication is required, which can be oil or graphite for lower temperature extrusions, or glass powder for higher temperature extrusions. The biggest disadvantage of this process is its cost for machinery and its upkeep.

Cold extrusionCold Extrusion is a push-through compressive forming process with the starting material (billet/slug) at room temperature. During the process, however, the deforming material undergoes deformation heating (conversion of deformation work to heat) to several hundred degrees. Typically, a punch is used to apply pressure to the billet enclosed, partially or completely, in a stationary die.

Advantages of Extrusion:

- Cost-effective for large-scale production with minimal waste.

- Versatile: Supports various materials and shapes.

- Customizable: Additives and design flexibility.

- Consistent quality and scalable production.

- Energy-efficient and integrates with other processes.

Disadvantages of Extrusion:

- Material limitations: Not all polymers are suitable.

- High setup costs: Equipment and dies are expensive.

- Dimensional variability: Cooling shrinkage and die swell.

- Shape limitations: Intricate designs are challenging.

- Quality control issues: Surface defects and material inconsistencies.

- Post-processing needs: Cutting, finishing, or coating required.

- Environmental concerns: Energy use and plastic waste.

Application of extrusion1.Construction Industry

- Pipes and tubing (e.g., PVC pipes, drainage systems).

- Window and door profiles (e.g., uPVC frames).

- Insulation materials (e.g., foam boards, weather seals).

- Plastic films and sheets (e.g., food packaging, shrink wraps).

- Containers and trays.

- Seals and gaskets.

- Wire and cable insulation.

- Interior trims and protective sheathing.

- Straws, ropes, and garden hoses.

- Plastic profiles for furniture or appliances.

- Wire and cable coatings.

- Conduits for electrical wiring.

- Catheters, tubing, and other medical-grade profiles.

- Conveyor belts and guides.

- Protective linings for machinery.

- Irrigation tubing and films.

- Greenhouse covers.

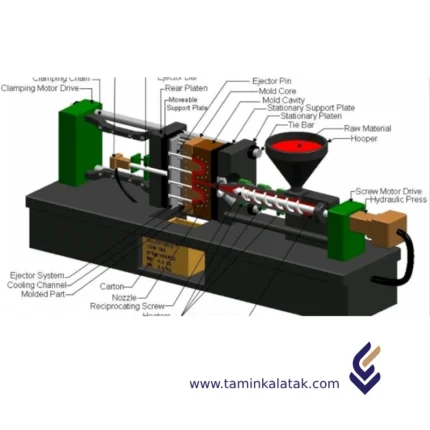

Injection Molding

Types of injection moldingGas-Assisted Injection Molding This process involves injecting gas (commonly nitrogen) into the molten polymer during molding. The gas pushes the molten plastic against the mold walls, creating hollow sections or reducing the amount of material used. Thin-Wall Injection Molding This method Focuses on producing parts with very thin walls, typically less than 1 mm. This requires specialized molds and machines capable of handling high pressures and fast cycle times. Liquid Silicone Rubber (LSR) Injection Molding This method is Used exclusively for liquid silicone rubber (LSR), a thermosetting material that cures when heated. LSR is injected into a heated mold, where it solidifies into a flexible and durable part. Structural Foam Molding A process where a foaming agent or gas is added to the polymer to create parts with a cellular core and solid outer skin. This reduces density and weight while maintaining strength. Metal Injection Molding (MIM) A process that combines metal powders with a polymer binder to create a feedstock. The feedstock is injected into a mold, then the binder is removed, and the part is sintered to achieve a dense metal component.

Advantages of injection molding

- Injection molding is incredibly cost-effective, especially in high-volume applications where thousands to tens of thousands of parts are printed in a workday.

- Injection molding offers many different materials, both general use, and specialty.

- Injection molding provides immense design freedom to product developers and is only held back by mold design, material specifications, and cost.

- Injection-molded parts can be as small as a grain of rice (or smaller) or can be as large as a car dashboard, depending upon the specific type of injection molding being used.

- Injection molding can produce highly complex parts that would otherwise be too time-consuming or difficult to produce with traditional subtractive manufacturing methods.

- Injection molding is a low/no waste manufacturing method, and waste can typically be 100% recycled and reground into stock material for a new injection mold.

Disadvantages of injection molding

- High initial tooling and equipment costs.

- Long lead times for mold design and production.

- Material limitations and risk of defects.

- Environmental and sustainability concerns.

- Design constraints requiring engineering expertise.

- Best suited for high-volume production.

Applications of injection moldingPlastic injection molding is used throughout industry as a means of manufacturing plastic parts in high volumes. Its applications are theoretically endless given the various types of injection molding available combined with its popularity. Still, there are some core usages for which the injection molding process particularly excels. Examples of injection molding applications include (but are not limited to):

- Automotive components

- Food and Beverage packaging

- Stock materials (spools, bar, tube, etc.)

- Toys and figurines

- Furniture components

- Fixtures and fasteners

- Mechanical components (gears, valves, pumps, linkages, etc.)

- Electronic hardware and housings

- Medical device components

- General plastic parts

Low Density PolyEthylene Injection (LDPE)

StructureThe structure of LDPE injection molding grade is characterized by a highly branched, amorphous polymer configuration, which distinguishes it from other forms of polyethylene such as High-Density Polyethylene (HDPE). The polymer chains in LDPE are irregularly branched, meaning the chains do not pack closely together, resulting in a low degree of crystallinity. The polymerization of LDPE occurs through free-radical polymerization, typically under high pressure, which causes the long chains of the polymer to have side branches. For the injection molding grade, the polymer structure is tailored to achieve a higher melt flow index (MFI), which facilitates the material's smooth flow and filling into injection molds.

PropertiesLDPE injection molding grade is a versatile polymer characterized by its high degree of branching and amorphous structure, which results in excellent flexibility. This material ensures smooth and efficient flow during the injection molding process. This makes it suitable for producing intricate parts with good surface finish. LDPE injection molding grade exhibits moderate tensile strength (around 8-12 MPa) and excellent elongation at break, providing resistance to cracking and impact. The material is also known for its good chemical resistance, particularly against acids, bases, and alcohols, while being less resistant to hydrocarbons. Additionally, it offers low moisture absorption and performs well under low temperatures, maintaining its flexibility. LDPE is easy to process and heat sealable. Despite its high impact resistance and toughness, it has a relatively low stiffness compared to higher-density polyethylene grades.

Applications

- Consumer Products:

- Household containers, lids, and dispensers

- Toys and other recreational items

- Furniture parts and lightweight molded components

- Packaging Industry:

- Caps, closures, and flexible lids

- Cosmetic and personal care packaging

- Food storage containers (FDA-approved grades)

- Medical & Pharmaceutical:

- Syringes, laboratory equipment, and sterile packaging

- Medical device housings and disposable instruments

- Industrial & Electrical:

- Cable coatings and wire insulation

- Protective covers and soft-touch components

- Pipes and low-pressure fittings

- Automotive Industry:

- Interior trims, protective covers, and soft components

- Fluid storage containers and under-the-hood parts

- Construction & Agriculture:

- Waterproofing membranes, gaskets, and sealants

- Molded irrigation components

Advantages

- Excellent Processability

- High Flexibility & Impact Resistance

- Lightweight Material

- Good Chemical & Moisture Resistance

- Food-Safe and Non-Toxic

- Cost-Effective

Disadvantages

- Low Mechanical Strength

- Limited Heat Resistance

- Poor UV Resistance

- Not Biodegradable

- Weak Barrier Properties

PolyPropylene (PP Chemical)

Structure of Polypropylene (PP)Polypropylene (PP) is a semi-crystalline thermoplastic polymer derived from propene (C₃H₆) monomers through the polymerization process.

- Molecular Structure:

- Composed of repeating propylene units (C₃H₆) linked together in a chain-like structure.

- Exists in three main forms:

- Isotactic PP – Most commonly used, with all methyl groups (CH₃) aligned on one side of the polymer chain, resulting in high crystallinity and strength.

- Syndiotactic PP – Alternating arrangement of methyl groups, making it more flexible but less crystalline.

- Atactic PP – Random arrangement of methyl groups, leading to an amorphous structure with low strength.

- Polymerization Process:

- Polypropylene is synthesized using Ziegler-Natta catalysts or metallocene catalysts in industrial polymerization reactions.

- It is classified as a thermoplastic, meaning it can be melted and reshaped multiple times without significant degradation.

Properties of Polypropylene (PP)Polypropylene possesses a combination of mechanical, thermal, and chemical properties, making it ideal for diverse applications.

1. Mechanical Properties:

✔ High Tensile Strength – Strong yet lightweight, making it ideal for packaging and textiles. ✔ Impact Resistance – Can withstand moderate shocks and impacts. ✔ Good Elasticity & Flexibility – Suitable for films, fibers, and flexible containers.2. Thermal Properties:

✔ High Melting Point (~160°C - 170°C) – More heat-resistant than polyethylene (PE). ✔ Low Thermal Conductivity – Acts as an insulating material. ✔ Resistant to Temperature Fluctuations – Can handle both hot and cold environments.3. Chemical Properties:

✔ Resistant to Acids, Alkalis, and Solvents – Does not degrade easily when exposed to chemicals. ✔ Low Water Absorption – Maintains mechanical properties in humid environments. ✔ Good Fatigue Resistance – Ideal for repeated bending applications like hinges.4. Electrical Properties:

✔ Excellent Electrical Insulation – Used in wires, cables, and electrical components.5. Environmental Properties:

✔ Recyclable (#5 plastic code) – Can be reused in eco-friendly applications. ✔ UV Sensitivity – Can degrade when exposed to prolonged UV radiation unless treated with stabilizers.Applications of Polypropylene (PP)

- Packaging Industry

- Textile Industry

- Automotive Industry

- Medical & Healthcare Applications

- Household & Consumer Products

- Industrial Applications

Advantages of Polypropylene (PP)✔ Lightweight & Strong – Provides durability without adding extra weight. ✔ Excellent Chemical Resistance – Withstands exposure to acids, bases, and solvents. ✔ High Heat Resistance – Can be used in microwaves and hot water applications. ✔ Waterproof & Moisture-Resistant – Ideal for food packaging and textiles. ✔ Recyclable & Eco-Friendly – Can be reused, reducing plastic waste. ✔ Affordable & Cost-Effective – Inexpensive compared to other polymers. ✔ Non-Toxic & Safe – Used in medical and food-grade applications.

Disadvantages of Polypropylene (PP)✘ UV Degradation – Can become brittle when exposed to sunlight for long periods unless UV stabilizers are added. ✘ Low Impact Resistance at Low Temperatures – Can crack in extremely cold conditions. ✘ Flammability – Easily combustible and requires flame retardants for certain applications. ✘ Difficult to Paint or Glue – Requires special surface treatments for adhesion. ✘ Limited Transparency – Unlike PET, PP is not completely clear. ✘ Environmental Concerns – Though recyclable, it is not biodegradable, leading to plastic waste issues.

Suspension

StructurePolyvinyl Chloride (PVC) suspension grade is a thermoplastic polymer produced through the suspension polymerization process. In this method, vinyl chloride monomer (VCM) is dispersed in water with the help of suspending agents and polymerized using free radical initiators. The resulting PVC resin consists of fine, porous, and free-flowing particles with a relatively high molecular weight, making it suitable for a wide range of applications. The polymer structure is primarily composed of repeating vinyl chloride units (–CH₂–CHCl–), forming a linear polymer chain with varying degrees of polymerization. PVC suspension grade is widely used in the manufacturing of pipes, fittings, films, sheets, and rigid as well as flexible products due to its excellent mechanical strength, durability, and chemical resistance. The properties of the resin, such as particle size, porosity, and bulk density, can be adjusted by controlling the polymerization conditions, making it versatile for different industrial applications.

PropertiesPVC suspension grade exhibits a combination of excellent physical, mechanical, and chemical properties, making it highly versatile for industrial applications. It appears as a white, free-flowing powder with a bulk density ranging from 0.45 to 0.65 g/cm³ and a particle size typically between 50-250 microns. Its high porosity allows for better plasticizer absorption, making it suitable for both rigid and flexible products. Mechanically, it offers good tensile strength, typically between 40-60 MPa, and moderate to high impact resistance, which can be enhanced with additives. Chemically, PVC suspension grade is highly resistant to acids, bases, and many chemicals, ensuring durability in harsh environments. It also has low water absorption, which provides excellent dimensional stability. However, it is susceptible to UV degradation, requiring stabilizers for outdoor applications. These properties make PVC suspension grade ideal for manufacturing pipes, profiles, films, and various other rigid and flexible products.

Applications

- Construction Industry: Pipes, fittings, window profiles, doors, roofing sheets

- Packaging Industry: Films, sheets, bottles

- Automotive Industry: Interior trims, dashboards, wire insulation

- Medical Sector: Tubing, blood bags, IV containers

- Electrical Applications: Cable insulation, coatings

Advantages

- High durability and strength – Ideal for long-term use

- Excellent chemical resistance – Withstands acids, bases, and oils

- Cost-effective – Affordable compared to other polymers

- Low water absorption – Ensures dimensional stability

- Easily processable – Can be molded, extruded, and shaped easily

- Customizable – Properties can be modified with additives

Disadvantages

- UV degradation – Becomes brittle under prolonged sunlight exposure

- Toxic gas release – Emits harmful gases (HCl) when burned

- Health concerns – Some plasticizers used in flexible PVC may have risks

- Not biodegradable – Raises environmental concerns regarding disposal

TetrafluoroEthylene/perfluoroPropylene copolymers (FEP)

StructureThe structure of Tetrafluoroethylene/Perfluoropropylene (FEP) copolymer consists of a randomly distributed backbone of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP) monomer units. The TFE units provide the high thermal and chemical resistance characteristic of fluoropolymers, while the HFP units introduce branching that disrupts crystallinity, enhancing flexibility and melt processability. The polymer chain is composed of repeating –CF₂–CF₂– segments from TFE and –CF₂–CF(CF₃)– segments from HFP, where the bulky trifluoromethyl (-CF₃) groups reduce intermolecular forces, lowering the melting point compared to PTFE. This molecular architecture results in a copolymer with excellent non-stick properties, chemical inertness, and transparency while being more easily processed using conventional melt-processing techniques.

PropertiesTetrafluoroethylene/Perfluoropropylene (FEP) copolymers exhibit a unique combination of thermal stability, chemical resistance, electrical insulation, and mechanical flexibility. They can withstand continuous exposure to high temperatures up to 200°C (392°F) while maintaining their structural integrity. FEP is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it ideal for harsh environments. Its non-stick and low-friction surface prevents adhesion and contamination, similar to PTFE. Unlike PTFE, FEP is melt-processable, allowing for fabrication through extrusion, injection molding, and blow molding. It also possesses excellent electrical insulating properties, with a low dielectric constant and high breakdown voltage, making it a preferred choice for wire and cable insulation. Additionally, FEP is optically transparent, resistant to UV radiation, and does not degrade under prolonged exposure to environmental factors, further enhancing its suitability for industrial, aerospace, and medical applications.

Applications of FEP Copolymers:

- Wire & Cable Insulation: Used in aerospace, automotive, and telecommunications due to high heat and chemical resistance.

- Chemical Processing Equipment: Linings for pipes, valves, and tanks in harsh chemical environments.

- Medical Tubing & Catheters: Biocompatible and resistant to sterilization processes.

- Food & Beverage Industry: Non-stick coatings for cooking equipment and food processing machinery.

- Semiconductor Industry: Used in chip manufacturing equipment due to high purity and chemical resistance.

- Heat Shrink Tubing: Provides electrical insulation and protection in extreme environments.

- Optical Fiber Coatings: Protects fibers in harsh conditions without affecting signal transmission.

- Laboratory Equipment: Used for beakers, flasks, and other chemical-resistant lab tools.

Advantages of FEP Copolymers:

- Excellent Chemical Resistance: Inert to most acids, bases, and solvents.

- High Thermal Stability: Can withstand temperatures up to ~200°C (392°F).

- Non-Stick Properties: Similar to PTFE (Teflon), preventing adhesion of substances.

- Low Friction: Reduces wear in moving parts and improves efficiency.

- Electrical Insulation: High dielectric strength makes it ideal for electrical applications.

- Transparent & UV Resistant: Can be used in optical and outdoor applications.

- Biocompatibility: Safe for medical and food-contact applications.

Disadvantages of FEP Copolymers:

- Lower Mechanical Strength: Weaker than PTFE in terms of tensile strength and wear resistance.

- Higher Cost: More expensive than common plastics like PVC or polyethylene.

- Limited Temperature Resistance: Slightly lower thermal stability than PTFE.

- Difficult Processing: Requires specialized molding and extrusion techniques.

- Fluorine Emission on Decomposition: Can release toxic fumes if overheated beyond its thermal limits.

Reviews

There are no reviews yet.