ThermoPlastic Elastomer

Thermoplastic elastomers (TPE) are a unique combination of properties of both plastics and rubber. These materials have both the flexibility and elasticity of rubber and the thermal processability of plastics. This unique combination has made TPEs one of the most popular materials in various industries.

TPE are typically composed of two or more polymers linked together in a block or branched structure. This structure allows them to have both elastomeric and thermoplastic properties.

Applications of TPEs

TPEs are used in a variety of industries due to their unique properties, including:

Automotive industry: Interior parts of cars such as gear levers, seat covers, and under-hood parts.

Medical industry: Medical gloves, medical tubing, and other medical equipment.

Sports industry: Athletic shoes, balls, and other sports equipment.

Packaging: Flexible packaging, airbags, and protective packaging.

Home use: Home appliances, toys, and other consumer products.

Electronic industry: Protective coverings for cables and electronic components.

ThermoPlastic Elastomer

| Products | Grade | Elongation at break | Density (g/mm3) | Tensile strength | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|---|

| ThermoPlastic Elastomer | 200 – 375% | 1.15 – 1.25 g/cm³ | 10 – 45 MPa | ||||

| ThermoPlastic Elastomer |

| Applications | , , , |

|---|

You must be logged in to post a review.

Related products

Acrylonitrile Styrene Acrylate (ASA)

Acrylonitrile Styrene Acrylate structureASA is typically formed by grafting acrylonitrile and styrene onto an acrylic ester elastomer backbone. The acrylic ester phase provides the material with flexibility and impact resistance, while the acrylonitrile and styrene phases contribute to rigidity, chemical resistance, and surface finish.

Acrylonitrile Styrene Acrylate propertiesAcrylonitrile-Styrene-Acrylate (ASA) polymer exhibits a combination of properties that make it well-suited for outdoor and demanding applications. Acrylonitrile Styrene Acrylate (ASA) polymer is a thermoplastic known for its excellent weather resistance, high impact strength, and UV stability, making it ideal for outdoor applications. It combines the toughness of acrylonitrile, the rigidity of styrene, and the weather-resistant properties of acrylic ester, resulting in a material that maintains its color, gloss, and mechanical integrity even under prolonged exposure to sunlight and harsh environmental conditions. ASA is resistant to chemicals, heat, and environmental stress cracking, and it exhibits good processability, enabling it to be molded into complex shapes. Its durability and aesthetic qualities make it suitable for use in automotive parts, outdoor furniture, and building materials.

ApplicationAutomotive Industry

- Exterior Components: Used for manufacturing exterior parts like side view mirrors, radiator grilles, and trims due to its resistance to UV radiation and harsh weather conditions.

- Interior Components: Employed in dashboards, panels, and other interior parts requiring durability and aesthetic appeal.

- Roofing and Cladding: ASA is used in roofing sheets, siding, and cladding materials for its resistance to fading and cracking when exposed to sunlight.

- Windows and Doors: Frames and profiles made of ASA are durable and maintain their color over time.

- Casing and Enclosures: ASA is used in the production of enclosures for electronic devices, electrical components, and appliances due to its impact resistance and aesthetic surface finish.

- Connectors and Insulators: The polymer is valued for its insulating properties and stability.

- Outdoor Furniture: Widely used for chairs, tables, and other outdoor furniture because it retains color and strength under prolonged exposure to sunlight and rain.

- Household Items: Utilized in kitchen appliances, vacuum cleaners, and other durable goods.

- Filament Material: ASA is a popular material for 3D printing, especially for outdoor applications, as it offers better UV resistance compared to ABS.

Advantages

- High impact strength

- Good Processability

- Weather Resistance

- Color and Gloss Retention

- Durability

Disadvantages

- Limited High-Temperature Resistance

- Flammability

- Lower Strength Compared to Metals

- Environmental Impact

Blow Molding (BLOW)

Types of blow moldingContinuous Extrusion Blow Molding (EBM) Process:

- Molten plastic is continuously extruded in a tube-like form (parison).

- A mold clamps around the parison and inflates it with air.

- The part cools and solidifies before being ejected.

- Reciprocating Screw System: The screw moves back and forth to accumulate plastic before pushing it into the mold.

- Accumulator Head System: Plastic is stored in an accumulator before being discharged in a single shot.

- Plastic is first injection molded into a preform (small tube-like shape with a finished neck).

- The preform is then transferred to a blow mold and inflated.

- The final shape is formed, cooled, and ejected.

- Similar to IBM, but includes a stretching step before inflation to improve strength and clarity.

- The preform is reheated, stretched lengthwise, and then blown into shape.

- A parison is extruded and clamped in a mold.

- The parison is stretched both axially (lengthwise) and radially (outward) before being inflated.

Advantages of blow molding

- Cost-Effective Production

- High Efficiency & Fast Production

- Ability to Produce Complex Shapes

- Lightweight and Durable Products

- Versatile Material Usage

- Suitable for Large & Small Products

Disadvantages of blow molding

- Limited to Hollow Shapes

- High Initial Equipment & Mold Costs

- Inconsistent Wall Thickness

- Weak Seams & Stress Points

- Less Precision Compared to Injection Molding

- High Energy Consumption

Applications of blow molding

- packaging Industry: Bottles for beverages, cosmetics, pharmaceuticals, and household products.

- Automotive Industry: Fuel tanks, air ducts, washer fluid reservoirs, and coolant tanks.

- Industrial & Chemical Storage: Drums, barrels, IBCs, and spray bottles.

- Medical & Pharmaceutical: IV bottles, medicine containers, and diagnostic device housings.

- Consumer Goods: Toys, furniture components, water bottles, and detergent containers.

- Construction Industry: Water tanks, septic tanks, pipes, and conduits.

- Agriculture Industry: Pesticide and fertilizer containers, watering cans, and irrigation components.

Ethylene TetraFluoroEthylene (ETFE)

StructureEthylene Tetrafluoroethylene (ETFE) is a copolymer composed of ethylene (C₂H₄) and tetrafluoroethylene (C₂F₄) units. Its molecular structure consists of a repeating chain of carbon atoms bonded to both fluorine and hydrogen atoms, giving it a unique combination of chemical resistance, mechanical strength, and thermal stability. The presence of fluorine atoms enhances its non-stick properties and high resistance to UV radiation, while the ethylene component contributes to its flexibility and toughness. Unlike polytetrafluoroethylene (PTFE), ETFE has a lower fluorine content, making it slightly less chemically inert but significantly stronger and more impact-resistant. This structural composition results in a lightweight, durable material that retains its transparency and mechanical properties even under extreme environmental conditions. ETFE's semi-crystalline structure also allows it to be processed into thin films, making it highly suitable for architectural applications, insulation, and protective coatings.

PropertiesEthylene Tetrafluoroethylene (ETFE) possesses a unique combination of properties that make it highly versatile across various applications. It is exceptionally lightweight, weighing only about 1% of the weight of glass, while maintaining high tensile strength and impact resistance. Its chemical structure provides outstanding resistance to ultraviolet (UV) radiation, weathering, and most chemicals, ensuring long-term durability in harsh environments. ETFE is highly transparent, allowing up to 95% of natural light to pass through, making it an excellent choice for architectural applications. Additionally, it has a low coefficient of friction, giving it self-cleaning and anti-fouling properties. The material is also highly flexible, capable of stretching up to three times its original length without losing integrity. With a high melting point of around 265°C (509°F), ETFE exhibits excellent thermal stability and can withstand extreme temperature fluctuations without degradation. Furthermore, it is a recyclable material, adding to its sustainability by reducing environmental impact. These combined properties make ETFE a preferred choice for applications in construction, aerospace, medical, and renewable energy industries.

Advantages

- Lightweight: Weighs only about 1% of the weight of glass.

- High Strength & Durability: Resistant to mechanical stress, impact, and punctures.

- Transparency: Allows up to 95% natural light transmission.

- UV & Weather Resistance: Does not degrade under prolonged sunlight exposure.

- Chemical Resistance: Withstands most acids, solvents, and other harsh chemicals.

- Self-Cleaning Surface: Low friction and non-stick properties prevent dirt accumulation.

- Thermal Stability: Can withstand extreme temperatures (-185°C to 150°C).

- Flexibility & Elasticity: Can stretch up to three times its length without damage.

- Eco-Friendly & Recyclable: Can be melted down and reused.

Disadvantages

- Higher Cost: More expensive than traditional materials like glass or polycarbonate.

- Flammability Concerns: Can burn under extreme conditions but is self-extinguishing.

- Limited Structural Support: Needs additional framing or inflation systems for strength.

- Softness & Scratch Sensitivity: Can be scratched more easily than glass.

- Noise Insulation: Provides less soundproofing compared to solid materials.

Applications

- Architecture & Construction: Used in stadiums, skylights, and domes (e.g., Allianz Arena, Eden Project).

- Aerospace & Automotive: Used for wire insulation and protective coatings.

- Medical Industry: Used for tubing, catheters, and biocompatible coatings.

- Chemical Industry: Lining for pipes and tanks due to its chemical resistance.

- Solar & Renewable Energy: Used in photovoltaic panel coatings and greenhouse covers.

- Electronics: Used in high-performance cable insulation for aerospace and telecommunications.

Ethylene Vinyl Acetate/ VAC- copolymers (EVA)

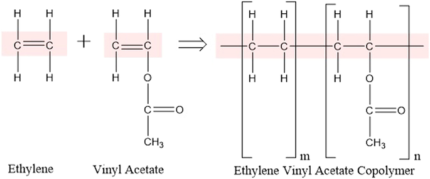

StructureEthylene Vinyl Acetate (EVA) is a copolymer composed of ethylene and vinyl acetate (VAC) monomers, with its structure characterized by randomly distributed vinyl acetate units within a polyethylene-like backbone. The proportion of vinyl acetate in the copolymer significantly influences its properties, with lower vinyl acetate content (typically below 10%) resulting in a more rigid, polyethylene-like material, while higher vinyl acetate content (above 40%) leads to a more rubbery and flexible structure. The presence of vinyl acetate disrupts the crystallinity of polyethylene, enhancing the copolymer’s flexibility, impact resistance, and transparency. EVA exhibits a balance between thermoplastic and elastomeric properties, making it widely used in applications such as adhesives, foams, films, and footwear. Its molecular structure provides excellent toughness, stress-crack resistance, and adhesion to various substrates, making it a versatile polymer in multiple industries.

PropertiesEthylene Vinyl Acetate (EVA) copolymers exhibit a unique combination of properties that vary based on the vinyl acetate (VAC) content. They offer excellent flexibility, elasticity, and toughness, with higher VAC content leading to increased softness, transparency, and impact resistance. EVA has low-temperature resistance, maintaining flexibility even at sub-zero temperatures, and demonstrates good stress-crack resistance. It is also lightweight, has a low density, and provides excellent adhesion to various substrates, making it ideal for adhesives and coatings. Additionally, EVA is resistant to UV radiation and environmental stress, contributing to its durability in outdoor applications. It has good chemical resistance to water, oils, and certain solvents, though it may degrade under high temperatures or prolonged exposure to strong chemicals. The copolymer is also non-toxic, making it suitable for medical and food-contact applications. Its thermal and electrical insulation properties further enhance its versatility in industrial, packaging, and footwear applications.

Applications of Ethylene Vinyl Acetate (EVA) Copolymers:

- Footwear: Used in midsoles, insoles, and outsoles for cushioning and flexibility.

- Adhesives: Hot melt adhesives in packaging, bookbinding, and woodworking.

- Foams: Sports mats, yoga mats, and padding materials.

- Packaging: Film applications for food packaging and medical films.

- Automotive: Interior trims, soundproofing, and under-the-hood components.

- Solar Panels: Encapsulation of photovoltaic cells for durability and insulation.

- Wire & Cable Insulation: Used in electrical applications due to flexibility and insulation properties.

- Toys & Consumer Goods: Soft, flexible materials for safety and durability.

Advantages of EVA Copolymers:

- Flexibility & Softness: Offers rubber-like elasticity and comfort.

- Lightweight: Reduces overall product weight while maintaining durability.

- Good Adhesion: Bonds well with various substrates, making it ideal for adhesives.

- Weather & UV Resistance: Suitable for outdoor applications like solar panels and footwear.

- Chemical Resistance: Resists many chemicals, oils, and solvents.

- Low-Temperature Performance: Maintains flexibility in cold conditions.

- Non-Toxic & Safe: Used in food packaging and medical applications.

Disadvantages of EVA Copolymers:

- Lower Heat Resistance: Can degrade or deform at high temperatures.

- Lower Mechanical Strength: Compared to other thermoplastics like polyethylene or polypropylene.

- Aging & Degradation: May degrade over time when exposed to UV radiation or harsh conditions.

- Flammability: Not inherently flame-retardant without additives.

- Cost: Can be more expensive than some alternative plastics like PVC.

High Density PolyEthylene Film (HDPE)

Structure

The structure of High-Density Polyethylene (HDPE) is characterized by long, linear chains of repeating ethylene units (–CH₂–CH₂–) with minimal or negligible branching. This linear configuration allows the polymer chains to pack closely together, resulting in a high degree of crystallinity (up to 80-90%) and a dense molecular arrangement. The compact structure enhances intermolecular van der Waals forces, giving HDPE its high tensile strength, rigidity, and chemical resistance. The lack of branching, achieved through polymerization methods like Ziegler-Natta or metallocene catalysis, is a defining feature that differentiates HDPE from other polyethylene types, such as Low-Density Polyethylene (LDPE). This tightly packed and highly organized structure makes HDPE a robust and durable material, widely used in industrial and consumer applications.Properties

- High Strength-to-Density Ratio: While lightweight, HDPE exhibits excellent tensile strength, making it suitable for heavy-duty applications.

- Chemical Resistance: It is resistant to a wide range of chemicals, acids, and bases, ensuring durability in corrosive environments.

- Low Moisture Absorption: HDPE’s low water absorption ensures its effectiveness in moisture-prone applications.

- Flexibility and Impact Resistance: It withstands impact and environmental stress, even under extreme conditions.

- Thermal Resistance: HDPE maintains integrity in a broad temperature range, making it ideal for outdoor and industrial uses.

Applications

HDPE plastic is used in a laundry list of applications, as it is currently one of the most versatile plastic materials worldwide. Its strength, impact and corrosion resistance, chemical profile, and other valuable characteristics make it an ideal product material for various industries. Below is a brief list of some of the many uses of HDPE plastic:- Corrosion-resistant piping, HDPE sheet, and stock material

- Fuel tanks

- Food and beverage containers, plastic bottles, milk jugs, cups, etc.

- Shampoo/conditioner bottles, ointment tubes, personal care product containers, etc.

- Trash cans, recycle bins, plastic containers, etc.

- Bread bags, cereal box liners, food storage containers, etc.

- Laundry detergent bottles

- Recycled plastic lumber and composites

- Medical equipment

- 3D printing filament

- Boating components

- Coax cable insulators

- Sewage mains

- Pyrotechnic components

Advantages

- High strength-to-weight ratio

- Low friction coefficient and low moisture absorption

- High impact strength, resistant to dents and scratches

- Mold, mildew, rotting, mineral acids/bases, soil, and weather-resistant

- Resistant to chemicals, water, solvents, acids, detergents, and cleaning fluids

- Very malleable when heated and experiences medium to low shrinkage

- Easily recycled

- Can be sterilized via boiling, does not harbor bacteria well, and is dishwasher safe

- Replaces heavier materials in some applications

- Cost-effective

Disadvantages

- In certain forms, it can be flammable as it is a petroleum-based product

- Exhibits high thermal expansion

- Weak to oxidizers and chlorinated hydrocarbons

- Difficult to bond

- Sensitive to stress-cracking in suboptimal environments

Linear Low Density Polyethylene (LLDPE)

StructureLLDPE has a unique linear molecular structure with short, controlled branches. This structure is different from LDPE (Low-Density Polyethylene), which has long and irregular branches. LLDPE consists of ethylene monomers (–CH₂–CH₂–) linked in a linear fashion. It has short, uniform side branches created by copolymerizing ethylene with α-olefins (like butene, hexene, or octene).These branches prevent the polymer chains from packing too tightly, giving LLDPE low density and flexibility.

PropertiesLLDPE (Linear Low-Density Polyethylene) is a versatile thermoplastic polymer known for its excellent flexibility, high impact resistance, and good tensile strength. it is slightly denser than LDPE but less rigid than HDPE, making it ideal for applications requiring toughness and stretchability. It has a high elongation at break (>500%), allowing it to withstand significant stretching without tearing. LLDPE exhibits excellent chemical resistance against acids, bases, and alcohols while maintaining low water absorption, making it suitable for moisture-sensitive applications. Thermally, it has a melting point of approximately 110–125°C and remains functional between -50°C and 60°C. Though it lacks inherent UV resistance, stabilizers can be added to improve durability under sunlight. Its ease of processing through extrusion, blow molding, and film manufacturing makes it widely used in plastic films, flexible tubing, cable insulation, and various molded products. While lldpe is non-biodegradable, it is recyclable, contributing to sustainable material management.

Applications of Linear Low-Density Polyethylene (LLDPE)

- Packaging Industry:

- Stretch films and shrink wraps

- Plastic bags (grocery, trash, and industrial)

- Food packaging films (cling wraps, pouches)

- Agricultural Sector:

- Greenhouse films and mulch films

- Drip irrigation tubing and water storage tanks

- Industrial Applications:

- Pipes and fittings (flexible and durable)

- Cable insulation and protective coatings

- Industrial liners (chemical and water-resistant)

- Automotive Industry:

- Fuel tanks and hoses

- Interior soft components and protective covers

- Consumer & Household Products:

- Toys, containers, and household items

- Soft-touch grips and molded parts

- Medical & Pharmaceutical:

- Medical tubing and IV bags

- Sterile packaging films

Advantages of LLDPE

- Higher Flexibility and Toughness:

- More impact-resistant than LDPE

- Maintains durability even at low temperatures

- Excellent Chemical and Moisture Resistance:

- Resistant to acids, bases, and solvents

- Waterproof and corrosion-resistant

- Good Processability

- Lightweight and Cost-Effective

- Better Puncture and Tear Resistance:

- Ideal for thin film applications like stretch wraps

Disadvantages of LLDPE

- Lower Heat Resistance:

- Softens and deforms at high temperatures

- Not suitable for high-temperature applications

- Poor UV Stability:

- Requires UV stabilizers for outdoor use, or it degrades over time

- Lower Stiffness Compared to HDPE:

- Less rigid, making it unsuitable for structural applications

- Limited Gas Barrier Properties:

- Not ideal for gas-tight packaging applications

- Difficult to Process in Some Applications:

- Requires higher processing temperatures compared to LDPE

Styrenic Block Copolymers (TPS)

StructureStyrenic block copolymers (TPS) have a phase-separated structure composed of alternating hard and soft polymer segments. The hard segments consist of polystyrene (PS) domains, which provide strength, rigidity, and thermal stability, while the soft segments are made of elastomeric materials such as polybutadiene (PB), polyisoprene (PI), or ethylene-butylene (EB), contributing to flexibility and elasticity. These block copolymers form a physical crosslinking network where the polystyrene blocks aggregate into discrete domains, acting as physical anchors that hold the material together, while the rubbery segments remain continuous and provide elasticity. This unique morphology allows TPS materials to behave like thermoset elastomers at room temperature but soften and flow when heated, making them fully thermoplastic and easily reprocessable. The phase separation between the polystyrene and elastomeric segments gives TPS its characteristic combination of strength, flexibility, and processability, making it widely used in applications requiring both durability and soft-touch properties.

PropertiesStyrenic block copolymers (TPS) exhibit a unique combination of elasticity, strength, and processability due to their phase-separated structure. They have excellent flexibility and rubber-like elasticity, allowing them to stretch and recover their shape without permanent deformation. Their mechanical properties include good tensile strength and impact resistance, making them durable for various applications. TPS materials have moderate heat resistance, generally performing well below 100°C, and are resistant to many oils, greases, and chemicals, enhancing their stability in demanding environments. They also have good adhesion properties, making them suitable for overmolding onto other plastics. Unlike thermoset rubbers, TPS materials are thermoplastic, meaning they can be melted, reshaped, and recycled multiple times, improving manufacturing efficiency and sustainability. They also provide a soft-touch feel, making them ideal for grips, handles, and other ergonomic applications. Additionally, TPS offers good weather resistance, especially in formulations like SEBS, which enhance UV and oxidation stability. These combined properties make TPS widely used in automotive, medical, consumer goods, and adhesive applications.

Application

- Automotive Industry:

- Soft-touch interior components (dashboards, door panels)

- Seals, gaskets, and vibration dampeners

- Grip pads and protective coatings

- Consumer Goods:

- Handles and grips for tools, toothbrushes, and razors

- Sports equipment, shoe soles, and protective gear

- Flexible packaging and stretchable films

- Medical Applications:

- Medical tubing and syringe plungers

- Overmolded soft-touch medical devices

- Flexible, biocompatible components

- Adhesives and Sealants:

- Pressure-sensitive adhesives (PSAs)

- Hot-melt adhesives for packaging and footwear

- Electronics & Electrical:

- Protective casings for devices

- Wire and cable insulation

AdvantagesHigh Elasticity and Flexibility – Provides rubber-like stretch and softness Good Impact and Tensile Strength – Enhances durability and wear resistance Thermoplastic Nature – Can be easily melted, reshaped, and recycled Soft-Touch Feel – Ideal for ergonomic grips and overmolding Good Adhesion to Various Materials – Suitable for multi-material applications Resistant to Oils, Greases, and Chemicals – Performs well in harsh environments Lightweight – Reduces material costs and improves energy efficiency Good Weather and UV Resistance – Certain formulations (e.g., SEBS) have enhanced outdoor durability Easy Processing – Compatible with injection molding, extrusion, and blow molding

DisadvantagesLower Heat Resistance – Limited performance above 100°C Lower Stiffness Compared to Some Plastics – May require reinforcement for structural applications Can Become Sticky in Hot Conditions – Some grades may soften and lose shape retention Higher Cost Than Standard Plastics – More expensive than traditional polyolefins like PP and PE Limited Load-Bearing Capacity – Not suitable for heavy-duty mechanical applications

Textile Grade

- Molecular Structure:

- Natural fibers have a cellulose-based (plant fibers) or protein-based (animal fibers) molecular structure.

- Synthetic fibers are often derived from polymer chains, such as polyethylene terephthalate (PET) in polyester.

- Fiber Morphology:

- Fibers are classified as filament (long, continuous fibers like silk) or staple (short fibers like cotton).

- Processing techniques such as spinning, weaving, and knitting alter fiber orientation for enhanced strength and flexibility.

- Surface Treatment:

- Textile grade materials undergo chemical treatments such as dyeing, anti-static coating, moisture-wicking finishes, and UV protection to enhance their functionality.

PropertiesTextile grade materials possess distinct characteristics that make them suitable for various applications:

1. Mechanical Properties

✔ High Tensile Strength – Ensures durability and resistance to tearing. ✔ Elasticity – Some fibers (like spandex) stretch and recover their shape. ✔ Abrasion Resistance – Important for heavy-use applications like upholstery and workwear.2. Thermal Properties

✔ Heat Resistance – Some fibers (e.g., aramid, wool) withstand high temperatures. ✔ Low Melting Point – Certain synthetics (e.g., polyester) require controlled heat processing.3. Chemical Properties

✔ Moisture-Wicking – Polyester and nylon repel moisture, keeping fabrics dry. ✔ Chemical Resistance – Some textile grades resist acids, alkalis, and solvents. ✔ UV Protection – Certain fibers (e.g., acrylic) naturally block UV rays.4. Environmental Properties

✔ Biodegradability – Natural fibers decompose over time, unlike synthetics. ✔ Sustainability – Eco-friendly textile grades include organic cotton, recycled polyester, and bamboo fibers.ApplicationsTextile grade materials are used across multiple industries, including fashion, home textiles, and technical applications.

1. Apparel Industry

- Clothing – Shirts, pants, jackets, and sportswear.

- Performance Fabrics – Moisture-wicking athletic wear, compression garments.

- Luxury Textiles – Silk, high-thread-count cotton, and premium synthetic blends.

2. Home Textiles

- Upholstery – Durable fabrics for sofas, curtains, and carpets.

- Bedding – Sheets, blankets, and pillowcases.

- Towels & Linens – Cotton-based materials for comfort and absorbency.

3. Industrial & Technical Textiles

- Automotive Textiles – Car seats, airbags, and interior linings.

- Medical Textiles – Surgical gowns, bandages, and antimicrobial fabrics.

- Protective Gear – Fire-resistant clothing (e.g., Nomex), bulletproof vests (Kevlar).

4. Eco-Friendly & Sustainable Applications

- Recycled Textiles – Upcycled polyester from plastic bottles.

- Organic Fibers – Bamboo, hemp, and organic cotton for sustainable fashion.

AdvantagesDurability – Textile grade materials are engineered for longevity. Versatility – Suitable for various applications, from fashion to industry. Lightweight & Comfortable – Many textiles are breathable and easy to wear. Easy Maintenance – Many fibers resist stains, wrinkles, and shrinkage. Cost-Effective – Mass production of synthetics reduces costs. Sustainability Options – Growing availability of eco-friendly textile grades.

DisadvantagesEnvironmental Concerns – Many synthetic fibers are non-biodegradable and contribute to plastic pollution. Flammability – Some textiles require fire-resistant treatments for safety. Chemical Sensitivity – Certain materials degrade when exposed to strong detergents, acids, or UV light. Heat Sensitivity – Synthetic fibers like polyester melt at high temperatures, limiting ironing options. Moisture Absorption Issues – Some fibers retain or repel moisture excessively, impacting comfort.

Reviews

There are no reviews yet.