Tread Rubber

Tread Stitcher

Tread Winding Machine

Tri Ethanol Amine

Triethanolamine (TEA) is an organic compound with the chemical formula C₆H₁₅NO₃, classified as a tertiary amine and a tri-hydric alcohol.

It is produced by the reaction of ethylene oxide with ammonia, and contains three hydroxyl (-OH) groups and one tertiary amine (-N<) functional group.

Molecular Structure:

HO–CH₂–CH₂–N(CH₂CH₂OH)₂

This structure enables TEA to act as a weak base, emulsifier, pH stabilizer, and strong solvent in various formulations.

Physical and Chemical Properties

| Property | Value / Description |

|---|---|

| Appearance | Clear, colorless to pale yellow viscous liquid |

| Odor | Mild, ammoniacal, slightly sweet odor |

| Molecular Weight | 149.19 g/mol |

| Boiling Point | 335 – 335.4°C |

| Melting Point | ~21.2 – 21.6°C |

| Density (25°C) | 1.124 – 1.127 g/cm³ |

| Viscosity (25°C) | ~450 cP (relatively high) |

| Solubility | Completely miscible with water, ethanol, and acetone |

| pH (1% aqueous solution) | 10.5 – 11.5 |

Applications

1. Cosmetics and Personal Care

-

pH adjuster in creams and lotions

-

Emulsifying agent in shampoos and shaving gels

-

Foam booster in mild cleansing formulations

2. Oil, Gas, and Drilling

-

Corrosion inhibitor in oil and gas transportation systems

-

Additive in drilling fluids

3. Textile Industry

-

Lubricant and softening agent in dyeing and finishing processes

-

Dye fixative for synthetic fibers

4. Pharmaceuticals

-

Base for ointments, creams, and topical formulations

-

Used in slow-release tablet formulations

5. Paints, Inks, and Coatings

-

Viscosity stabilizer and pH regulator

-

Improves dispersion and prevents pigment settling

6. Cement and Construction

-

Grinding aid in cement production

-

Enhances workability and strength of concrete

Advantages

-

Excellent buffering capacity for pH control

-

High solubility in both aqueous and organic systems

-

Multifunctional — acts as solvent, surfactant, and complexing agent

-

Suitable for low-odor and non-irritating formulations

Disadvantages

-

May cause skin sensitization upon repeated contact

-

Limited thermal stability at elevated temperatures

-

Requires precise dosage control in cosmetic formulations

-

Potential to form nitrosamines in the presence of nitrites under certain conditions

Safety and Handling

GHS Classification:

-

H315: Causes skin irritation

-

H319: Causes serious eye irritation

-

H335: May cause respiratory irritation

Safety Precautions (HSE):

-

Use protective gloves, safety goggles, and ensure adequate ventilation

-

Avoid direct contact with skin and eyes, and prevent inhalation of vapors

-

Store in tightly closed containers at ambient temperature, away from direct sunlight

Transportation Information:

-

UN Number: 2491

-

Hazard Class: 8 (Corrosive substances)

Summary

Triethanolamine (TEA) is a versatile, multifunctional chemical widely used in formulation, refining, textile, and construction industries.

With its unique ability to control pH, stabilize emulsions, and enhance compatibility with diverse raw materials, TEA remains one of the most valuable additives in modern industrial chemistry.

Tri Iso Propanol Amine

Triisopropanolamine (TIPA) is an organic compound with the chemical formula C₉H₂₁NO₃, classified as a tertiary amine and polyhydric alcohol.

It is produced by the reaction of ammonia with isopropyl oxide or isopropanol, and contains three hydroxyl (-OH) groups and one tertiary nitrogen center, providing both basic and solubilizing properties.

Chemical Structure:

[(CH₃)₂CHOCH₂]₃N

TIPA acts as a weak base with excellent complexing and solvent capabilities in aqueous and polar systems.

Physical and Chemical Properties

| Property | Typical Value / Description |

|---|---|

| Appearance | Clear, colorless to very pale yellow liquid |

| Odor | Mild, amine-like with slight alcoholic note |

| Molecular Weight | 191.27 g/mol |

| Boiling Point | 305–310°C |

| Freezing Point | Approx. –20°C |

| Density (25°C) | 1.03–1.05 g/cm³ |

| Water Solubility | Completely miscible |

| pH (1% aqueous solution) | 10.5–11.5 |

Applications

1. Cement and Concrete Industry

-

Used as a grinding aid to enhance mill efficiency and reduce energy consumption

-

Improves compressive strength and hydration performance of concrete

2. Detergents and Personal Care Formulations

-

pH regulator in liquid soaps and cleaners

-

Emulsion stabilizer for surfactant-based systems

3. Paints, Coatings, and Inks

-

Prevents pigment agglomeration and enhances dispersion stability

-

Improves viscosity control in water-based paints

4. Oil and Gas Industry

-

Functions as a corrosion inhibitor in drilling and transport systems

5. Agricultural Chemicals

-

Used as a pH adjuster in liquid fertilizers and pesticide formulations

Advantages

-

Excellent solubility in water and alcohols

-

High thermal and chemical stability

-

Multifunctional role as pH regulator, lubricant, and defoaming controller

-

Non-volatile and safer handling compared to lower amines

Limitations

-

May cause skin and eye irritation upon direct contact

-

Can undergo thermal decomposition at elevated temperatures

-

Requires controlled dosing to prevent corrosion in certain systems

Safety and Handling

Hazard Statements (GHS):

-

H319: Causes serious eye irritation

-

H315: Causes skin irritation

-

H335: May cause respiratory irritation

Storage and Handling Recommendations:

-

Store in polyethylene or stainless-steel containers at 10–30°C

-

Keep away from heat sources and direct sunlight

-

Use personal protective equipment (PPE) including gloves, safety goggles, and respirators

-

In case of spill, dilute with plenty of water and collect safely

Summary

Triisopropanolamine (TIPA) is a high-performance, multifunctional chemical widely used across various industries.

Its primary roles include acting as a cement grinding aid, pH stabilizer, and emulsifying agent in detergents and coatings.

For reliable performance and consistent quality, TIPA should be sourced from certified suppliers that provide a valid Certificate of Analysis (COA) and technical support tailored to your application.

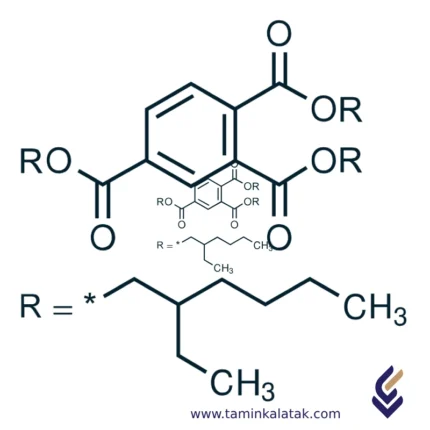

Tri Octyl Tri Mellitate (TOTM)

StructureThe structure of Tri-Octyl Trimellitate (TOTM) consists of a central trimellitic acid molecule, which is an aromatic dicarboxylic acid. This molecule is esterified with three octyl groups, which are derived from octyl alcohol, a long-chain alcohol. Each of the three octyl groups is attached to one of the carboxyl groups on the trimellitic acid via an ester bond. The octyl groups, with a carbon chain length of eight carbon atoms, contribute to the compound's high molecular weight and oily texture. The result is a molecule with a large, non-polar hydrophobic character, which provides its useful properties as a plasticizer. The overall molecular formula is C24H38O4, reflecting the combination of the aromatic trimellitic structure and the three octyl ester groups.

PropertiesTri-Octyl Trimellitate (TOTM) is a colorless to pale yellow liquid with a mild odor. It has a high molecular weight and a low volatility, which contributes to its stability in various applications. Its excellent thermal stability makes it suitable for use in high-temperature environments, as it can withstand temperatures without degrading. TOTM also exhibits low toxicity and is considered less harmful to both humans and the environment compared to some other plasticizers, such as phthalates. It has good compatibility with a wide range of polymers, particularly polyvinyl chloride (PVC), where it enhances flexibility and durability. Additionally, TOTM has low migration properties, meaning it does not easily leach out of plastics, which makes it ideal for long-lasting applications like electrical cables and automotive parts. The compound also has good resistance to aging, making it a reliable choice for products exposed to harsh conditions over extended periods. Its low volatility and high flash point add to its safety in industrial applications. Tri-Octyl Tri-Mellitate (TOTM) is a plasticizer used primarily in polymers like PVC to improve their flexibility, durability, and performance. Below are its applications, advantages, and disadvantages:

Applications of TOTM

- Plasticizer in PVC (Polyvinyl Chloride): TOTM is commonly used to improve the flexibility and processing of PVC compounds.

- Electrical Cable Insulation: It’s used in manufacturing insulation for electrical cables, offering resistance to heat, cold, and environmental factors.

- Coatings: Used in the production of durable and flexible coatings for various surfaces.

- Automotive Applications: In car interiors, particularly for making soft-touch surfaces and dashboard components.

- Medical Devices: Used in the production of flexible medical tubing and other PVC-based medical products.

- Packaging Materials: Provides flexibility to packaging films, improving their resistance to cracking.

Advantages of TOTM

- High Thermal Stability: TOTM provides excellent heat resistance, making it ideal for high-temperature applications.

- Good Electrical Insulation: Offers good electrical properties, which is particularly useful in the cable and wire industries.

- Low Volatility: TOTM has low volatility compared to other plasticizers, which reduces the likelihood of migration and volatilization over time.

- Durability: Offers long-lasting flexibility, making it suitable for products that require extended lifespans, such as electrical cables and medical devices.

- Non-Toxic: It is considered non-toxic and safer for use in medical and food-related applications when compared to other plasticizers.

Disadvantages of TOTM

- Higher Cost: TOTM is generally more expensive than other plasticizers, such as dioctyl phthalate (DOP).

- Lower Compatibility with Some Polymers: It may not be as compatible with all types of resins and can affect the processing of some materials.

- Reduced Processability: The use of TOTM may slightly reduce the processability of PVC due to its high molecular weight.

- Environmental Concerns: While safer than some other plasticizers, its environmental impact (especially in terms of biodegradability) may still be a concern.

Tricalcium phosphate

Trichlorethylene

Properties of Trichloroethylene

- Physical Properties:

- Colorless liquid

- Sweet odor

- Volatile

- Density greater than water

- Chemical Properties:

- Good solvent for many organic compounds

- Stable under normal conditions

- Decomposes at high temperatures to form toxic products

Past Applications of Trichloroethylene

- Industrial Solvent: Used in various industries for degreasing, cleaning, and as a solvent for paints, varnishes, and adhesives.

- Dry Cleaning: Employed in the dry cleaning industry.

- Medical Uses: Historically used as an anesthetic.

Environmental and Health Concerns

- Toxicity: Exposure to TCE can lead to a variety of health problems, including liver and kidney damage, nerve damage, and cancer.

- Environmental Pollution: TCE is a persistent organic pollutant that can contaminate groundwater and soil. It can also contribute to air pollution.

Triethanol amine alkyl benzene sulfonate linear salt 50%

Triethanolamine lauryl ether sulfate

triethanolamine lauryl sulfate 40%

Triethylene Glycol

Safety ConsiderationsWhile triethylene glycol is generally safe, it's important to handle it with care. It can cause skin and eye irritation. Inhaling its vapors can irritate the respiratory tract. Always follow safety guidelines and wear appropriate protective equipment when working with triethylene glycol.