Rotational Molding

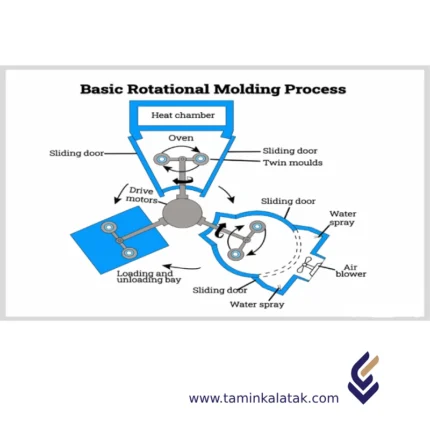

The rotational molding process is a straightforward yet effective method. In this technique, a plastic material, typically in powdered form, is placed inside a hollow mold. This mold is usually made of cast aluminum or fabricated from sheet steel. Once sealed, the mold rotates slowly around two axes. Simultaneously, it is heated inside an oven while continuously rotating. As the temperature rises, the plastic powder melts and evenly coats the inner surface of the mold. When the plastic has completely liquefied, the mold is transferred to a cooling station, where it is cooled using air or occasionally a fine mist of water. During this phase, the plastic gradually solidifies and takes its final shape. Once the material has cooled sufficiently and detaches from the mold’s surface, the process is halted, and the finished product is removed from the mold.

Types of rotational moldingClamshell Rotational Molding

- Uses a single-arm machine with an oven and cooling chamber combined.

- Best for smaller production runs or prototyping.

- Less efficient than multi-arm machines but requires less space.

- Designed for long and narrow products like kayaks and boats.

- The mold rotates on one axis while rocking back and forth on another axis.

- Ideal for making large, elongated parts with uniform wall thickness.

- Features two arms that shuttle between heating and cooling stations.

- Allows simultaneous molding and cooling, increasing production efficiency.

- Suitable for medium to large-scale manufacturing.

- Uses a vertical rotation system rather than the traditional horizontal axis.

- Provides more control over material distribution.

- Less common but useful for specific applications requiring precise thickness control.

- The most common and efficient type, often with three to four arms.

- Molds move continuously between loading, heating, cooling, and unloading stations.

- Ideal for high-volume production and large-scale manufacturing.

Advantages of rotational molding

- Cost-Effective Tooling – Molds are cheaper compared to injection or blow molding.

- Uniform Wall Thickness – Ensures even material distribution with no weak spots.

- Seamless and Hollow Structures – Produces one-piece parts without welds or joints.

- Design Flexibility – Allows for complex shapes, undercuts, and integrated features.

- Strong and Durable Products – High impact resistance with reinforced corners.

- Wide Range of Materials – Can use polyethylene (PE), polypropylene (PP), and nylon.

- Minimal Material Waste – Excess plastic can be recycled and reused.

- Large Part Capability – Ideal for tanks, containers, and oversized plastic products.

- Consistent and Repeatable Process – Ensures uniformity in mass production.

- Eco-Friendly Process – Lower energy consumption and recyclable materials.

Disadvantages of rotational molding

- Longer Cycle Times – Slower process compared to injection or blow molding.

- Higher Material Costs – Limited to specific thermoplastics, which can be more expensive.

- Limited to Hollow Parts – Not suitable for solid or highly detailed small components.

- Lower Precision and Tolerance – Less accuracy in dimensional control compared to injection molding.

- Limited Automation – More labor-intensive, leading to higher production costs for large runs.

- Surface Finish Limitations – May require post-processing for a smooth or polished surface.

- Lower Production Efficiency – Not ideal for high-volume production due to longer cycles.

- Thicker Walls Required for Strength – Thinner-walled parts may lack the necessary strength.

- Cooling Time Can Be Long – Extended cooling periods increase overall production time.

Applications of rotational molding

- Storage Tanks – Water tanks, fuel tanks, and chemical storage containers.

- Automotive Parts – Fuel tanks, air ducts, mudguards, and fenders.

- Industrial Containers – Bins, hoppers, and transport containers.

- Playground Equipment – Slides, climbing structures, and outdoor playsets.

- Furniture – Modern plastic chairs, tables, and decorative items.

- Marine & Boating – Kayaks, canoes, buoys, and dock floats.

- Medical Equipment – Enclosures, casings, and patient support devices.

- Agricultural Products – Feed storage bins, water troughs, and irrigation tanks.

- Recreational & Sports Gear – Helmets, cones, and protective padding.

- Road & Traffic Safety – Barriers, traffic cones, and road markers.

- Consumer Goods – Coolers, toolboxes, and custom cases.

Rubber Calender

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Compound

Rubber compound is a mixture of natural or synthetic rubber with various additives. These additives are added to improve the physical, chemical and mechanical properties of the base rubber. In fact, rubber compound can produce products with very diverse properties by changing the ratio and type of raw materials.

Rubber Compound PropertiesThe properties of rubber compounds depend on the type and amount of additives used. Some of the most important properties of rubber compounds are: Tensile strength: The compound's resistance to stretching Tear resistance: The compound's resistance to tearing Hardness: The compound's resistance to penetration Flexibility: The compound's ability to deform without cracking Abrasion resistance: The compound's resistance to abrasion and scratching Heat resistance: The compound's resistance to high or low temperatures Chemical resistance: The compound's resistance to chemicals such as oil, acid, and alkali

Rubber compound applicationsRubber compounds have very wide applications in various industries, including: Automotive industry: Production of tires, hoses, gaskets, wire coatings, etc. Construction industry: Production of thermal and acoustic insulation, flooring, and cable coatings Sports industry: Production of balls, sports shoes, mattresses, etc. Medical industry: Production of gloves, medical tubes, etc.

Rubber Crumb Premixing Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Cutting Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Extruder

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Hose Building Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Hose Curing/Vulcanizing Ove…

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Injection Molding Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Kneader

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Microwave Curing Machine

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.

Rubber Mixer and Feeding System

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vestibulum sagittis orci ac odio dictum tincidunt. Donec ut metus leo. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Sed luctus, dui eu sagittis sodales, nulla nibh sagittis augue, vel porttitor diam enim non metus. Vestibulum aliquam augue neque. Phasellus tincidunt odio eget ullamcorper efficitur. Cras placerat ut turpis pellentesque vulputate. Nam sed consequat tortor. Curabitur finibus sapien dolor. Ut eleifend tellus nec erat pulvinar dignissim. Nam non arcu purus. Vivamus et massa massa.