Polyvinyl alcohol

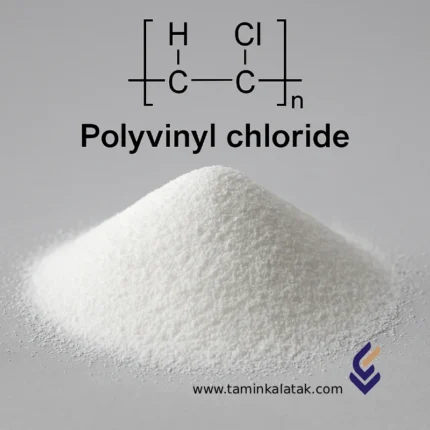

Polyvinyl chloride PVC

Polyvinyl Chloride (PVC) is one of the most widely used thermoplastic polymers in the world, produced by polymerization of vinyl chloride monomer (VCM).

Thanks to its excellent chemical resistance, adjustable flexibility, durability, and cost efficiency, PVC is used across diverse industries — from construction and electrical engineering to medical and automotive manufacturing.

Chemical Structure and Composition

-

Chemical Formula: (C₂H₃Cl)ₙ

-

Monomer: Vinyl Chloride (CH₂=CHCl)

-

Molecular Structure: Linear chains of repeating –CH₂–CHCl– units

-

Structural Type: Amorphous thermoplastic containing chlorine (~57% by weight)

The presence of chlorine atoms enhances PVC’s chemical resistance, flame retardancy, and dimensional stability compared to other common polymers like PE and PP.

PVC is available in two main types:

-

Rigid PVC (uPVC) – high strength, used in pipes and profiles

-

Flexible PVC (Plasticized PVC) – soft and elastic, used in films and cables

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Chemical Formula | (C₂H₃Cl)ₙ |

| Density | 1.35 – 1.45 g/cm³ |

| Melting Point | 75 – 105 °C (depending on additives) |

| Water Solubility | Insoluble |

| Solubility in Organics | Soluble in ketones, esters, and chlorinated solvents |

| Color | White or colorless (easily pigmented) |

| Chemical Resistance | Excellent resistance to acids, bases, and most solvents |

| Thermal Decomposition | Above 140 °C (releases HCl gas if overheated) |

Key Advantages

-

Cost-effective compared to other engineering plastics

-

Excellent chemical and corrosion resistance

-

Moisture-proof and resistant to microbial attack

-

Adjustable flexibility via addition of plasticizers

-

Good electrical insulation properties

-

Recyclable and compatible with sustainable manufacturing practices

Limitations

-

Sensitive to UV radiation – requires stabilizers for outdoor use

-

Thermal instability – decomposes if overheated, releasing hydrogen chloride (HCl)

-

Requires additives (stabilizers, lubricants, plasticizers) to enhance processing and durability

-

Lower impact resistance compared to some engineering thermoplastics

Main Applications of PVC

1. Construction Industry

-

Water and sewage pipes

-

Window and door profiles (uPVC)

-

Floor coverings, wall panels, roofing membranes

2. Electrical and Electronics

-

Cable and wire insulation

-

Electrical conduits and fittings

3. Packaging

-

Flexible films, shrink wraps, and transparent sheets

4. Medical Applications

-

Blood and IV bags, tubing, catheters, and medical-grade films

5. Automotive and Consumer Goods

-

Interior trims, dashboard coatings, seat coverings, and synthetic leather

Safety, Handling, and Storage

-

Storage: Keep in a cool, dry, and well-ventilated area away from direct sunlight and heat sources.

-

Handling: Ensure proper ventilation during processing to avoid exposure to fumes or dust.

-

Personal Protection: Use dust masks, gloves, and eye protection when handling powders or granules.

-

Fire Behavior: PVC is self-extinguishing due to its chlorine content but may release toxic gases (HCl) when burned.

-

Transportation: Packed in sealed, moisture-resistant bags or bulk containers under standard polymer transport regulations.

Summary

Polyvinyl Chloride (PVC) combines versatility, durability, and cost-effectiveness, making it one of the most valuable polymers in industrial applications.

Whether in rigid form for structural uses or flexible form for films and medical devices, PVC continues to play a critical role in modern materials engineering thanks to its adaptability, recyclability, and broad performance range.

Portable Screw Extruder

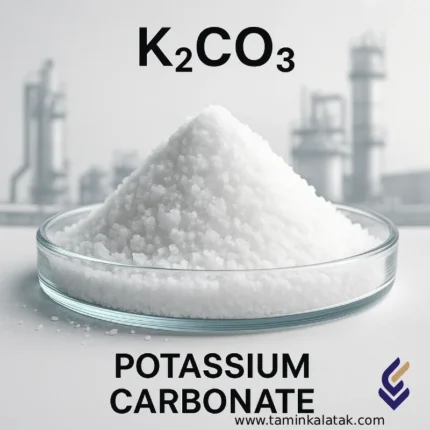

Potassium carbonate

Potassium Carbonate is an important inorganic compound with the chemical formula K₂CO₃. It appears as a white, odorless, highly hygroscopic crystalline powder and is well-known for its high solubility in water, strong alkalinity, and excellent chemical stability. These properties make it widely used across diverse industries — from glass manufacturing and ceramics to food, detergents, and pharmaceuticals.

Chemical Structure

Potassium Carbonate is an alkaline ionic salt, composed of two potassium ions (K⁺) and one carbonate ion (CO₃²⁻).

In its solid form, it has a monoclinic, anhydrous crystal structure.

In aqueous solution, it dissociates completely into free ions, producing a strongly alkaline pH, which makes it a moderately strong base suitable for buffering and neutralization processes.

Physical and Chemical Properties

| Property | Value / Description |

|---|---|

| Chemical Formula | K₂CO₃ |

| Molecular Weight | 138.205 g/mol |

| Density (20°C) | 2.43 g/cm³ |

| Melting Point | ~891°C |

| Boiling/Decomposition Point | >1200°C |

| Solubility (20°C) | Highly soluble (1120 g/L in water) |

| Appearance | White powder or granules, odorless |

| pH (10% solution) | ~11.6 |

| Stability | Stable under normal conditions; strongly hygroscopic |

| Flammability | Non-flammable and non-explosive |

Production Methods

Historically known as “potash”, Potassium Carbonate was once obtained from wood ash extraction. Modern industrial production now relies on controlled chemical processes, including:

-

Carbonation of Potassium Hydroxide (KOH):

CO₂ is bubbled through an aqueous KOH solution:

→ 2 KOH + CO₂ → K₂CO₃ + H₂O

The solution is evaporated and crystallized to obtain high-purity K₂CO₃. -

Electrolysis of Potassium Chloride (KCl):

KCl is electrolyzed to produce KOH, which is then carbonated with CO₂ to form K₂CO₃.

This is the most common modern industrial method. -

Traditional “Potash” Process (Historical):

Leaching potassium-rich plant ash with water and evaporating the lye solution — now largely obsolete due to low yield.

These methods ensure consistent particle size, high purity, and industrial or food-grade quality suitable for modern applications.

Applications

-

Glass Industry: Lowers melting temperature, enhances clarity and thermal resistance.

-

Detergent and Soap Production: Used as an alkaline agent in liquid soaps and industrial cleaners.

-

Food Industry (E501): Approved additive for pH regulation, stabilization, and acidity control. Common in cocoa powder alkalization, instant noodles, and carbonated beverages.

-

Fertilizers: A soluble potassium source for agriculture and hydroponic systems.

-

Ceramics and Glazes: Lowers firing temperature and improves glaze finish.

-

Metallurgy: Used as a flux and refining aid to remove impurities like sulfur.

-

Fire Suppression: Component in dry chemical fire extinguishers and flame-retardant formulations.

-

Pharmaceuticals: Buffer and pH adjuster in medical formulations.

-

Textile Processing: Employed for dye fixing and finishing of natural and synthetic fibers.

Advantages

-

Excellent solubility and easy handling in concentrated industrial solutions.

-

Rich potassium source, beneficial for agriculture and nutrition-related uses.

-

High chemical and thermal stability for long-term storage.

-

Broad industrial compatibility, suitable for glass, ceramics, metallurgy, and food.

-

Safer handling compared to stronger alkalis like Potassium Hydroxide (KOH).

Limitations

-

Highly corrosive in concentrated form; may cause skin and eye irritation.

-

Strongly hygroscopic, requiring moisture-proof packaging.

-

Strong alkalinity can corrode metals or sensitive equipment.

-

Dust inhalation hazard — protective masks are recommended during handling.

Safety and Handling Guidelines

-

Storage: Keep in a dry, cool, well-ventilated area, away from moisture and direct sunlight.

-

Protective Equipment: Use chemical-resistant gloves, goggles, and respiratory protection when handling powders.

-

Transportation: Store in moisture-proof packaging compliant with GHS and international shipping standards.

Emergency Measures:

-

Eye/Skin Contact: Rinse immediately with plenty of water and seek medical advice.

-

Inhalation: Move to fresh air and obtain medical assistance if symptoms persist.

-

Ingestion: Do not induce vomiting; seek medical attention promptly.

Summary

Potassium Carbonate (K₂CO₃) is a versatile, highly soluble alkali essential in modern chemical manufacturing.

Its combination of high purity, stability, and reactivity makes it invaluable in glassmaking, food processing, fertilizers, and pharmaceuticals, while its mild alkalinity ensures safe and effective industrial use.

Potassium Carbonate

Properties of Potassium CarbonateAlkalinity: An aqueous solution of potassium carbonate has a strong alkaline property. Moisture absorption: This substance is highly moisture-absorbent and for this reason is stored in closed containers. Solubility: It is highly soluble in water but insoluble in alcohols such as methanol and ethanol.

Potassium Carbonate ApplicationsGlass industry: It is used as a flux in glass production to reduce the melting temperature of raw materials and increase the viscosity of the melt. Soap industry: It is used as an alkaline agent in the production of soft and liquid soaps to saponify fats. Food industry: As an acidity regulator in foods As a leavening agent in some baked goods As a preservative in some foods Chemical industry: As a catalyst in some chemical reactions As a drying agent Other uses: In the production of dyes and inks In the production of batteries In water purification

Precautions when using potassium carbonateSkin and eye contact: Contact with skin and eyes can cause irritation and burns. Dust inhalation: Inhalation of dust from this substance can cause respiratory problems. Concentrated solutions: Concentrated solutions of potassium carbonate are highly corrosive.

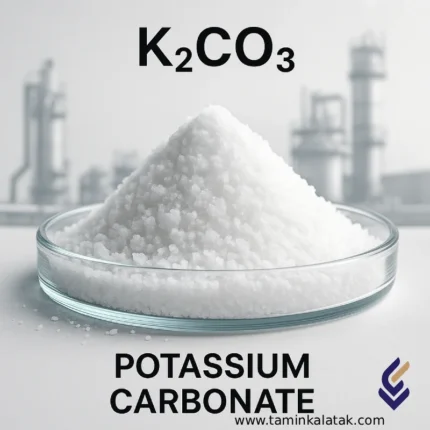

Potassium carbonate

Potassium carbonate is an important inorganic salt with the chemical formula K₂CO₃. It is available as a white, odorless powder or crystalline solid which is highly hygroscopic. Due to its high water solubility, strong alkalinity, and chemical stability, potassium carbonate finds a wide range of applications — from glass manufacturing to pharmaceuticals.

Chemical Structure of Potassium Carbonate

Potassium carbonate is an alkaline ionic salt comprised of two potassium ions (K⁺) and one carbonate ion (CO₃²⁻). In its solid state, it crystallizes in an anhydrous monoclinic structure. In aqueous solution the liberated potassium and carbonate ions confer strong alkaline characteristics and high pH, thereby functioning as a powerful base.

Physical and Chemical Properties

-

Chemical formula: K₂CO₃

-

Molecular weight: ~205 g/mol

-

Density: (Note: the figure “43 g/cm³” seems incorrect in original text — likely 2.43 g/cm³ or a mis-print)

-

Melting point: approx. 891 °C

-

Boiling/decomposition point: above 1,200 °C

-

Solubility in water (20 °C): 1,120 g/L – very high

-

Physical appearance: white powder or granules, odorless

-

pH of 10% solution: around 6 (Note: this is surprisingly low — may vary by grade)

-

Stability: stable under normal conditions, but highly hygroscopic

-

Flammability/explosion hazard: non-flammable and safe in normal conditions

Production Methods

Historically, potassium carbonate was made from wood ash. Today, industrial production is achieved via:

-

CO₂ reaction with potassium hydroxide (KOH):

2 KOH + CO₂ → K₂CO₃ + H₂O

After evaporation and crystallisation, high-purity K₂CO₃ is obtained. -

Electrolysis of potassium chloride (KCl):

First, KOH is generated by electrolysis of KCl. Then KOH reacts with CO₂ to yield K₂CO₃. This modern process is widely adopted in large-scale industries due to its high efficiency. -

Traditional method: Extraction from wood and plant ash – largely obsolete due to low yield and impurities.

These modern methods enable production of industrial or food-grade potassium carbonate with uniform granulation and high purity.

Applications of Potassium Carbonate

-

Glass Industry: Lowers melting point of glass, improves clarity and durability.

-

Detergent/Soap Industry: Serves as an alkaline agent in liquid soap and industrial cleaning formulations.

-

Food Industry (Food Additive E501): Functions as a pH regulator, stabiliser and anti-acid. Used in alkaline cocoa processing, instant noodles, carbonated drinks.

-

Chemical Fertiliser Production: A soluble source of potassium for agriculture and hydroponics.

-

Ceramic & Glaze Industry: Lowers firing temperatures and improves surface quality of glazes.

-

Metallurgy: Used as a flux, metal refining aid, and lubricant in metal smelting operations.

-

Firefighting: Ingredient in dry chemical extinguishers and fire-suppressant compositions.

-

Pharmaceuticals: Employed as a buffer and pH adjuster in selected formulations.

-

Textiles: Used in finishing and colour-fixing for natural and synthetic fibers.

Advantages of Potassium Carbonate

-

Very high solubility → enables concentrated industrial solutions.

-

Provides a rich source of potassium → crucial in agriculture and food sectors.

-

Chemically stable → long shelf life under proper storage.

-

Versatile across many industries: glass, metal, food, pharmaceutical, etc.

-

Safer alternative in some cases compared to stronger alkalis like KOH.

Limitations

-

Strong alkalinity → direct contact with skin or eyes may cause irritation or burns.

-

Hygroscopicity → demands moisture-proof packaging and dry storage.

-

Highly alkaline → may corrode metals and sensitive equipment.

-

Dust inhalation hazard → may irritate respiratory tract; dust masks recommended.

Safety and Storage

-

Storage conditions: Store in a dry, cool, well-ventilated environment, protected from direct sunlight.

-

Protective equipment: Wear chemical-resistant gloves, safety goggles, and respiratory protection when handling dust.

-

Transport & packaging: Use moisture-resistant, durable packaging and comply with chemical transport regulations.

-

Emergency response:

-

Skin/eye contact: Rinse immediately with plentiful water, seek medical attention.

-

Dust inhalation: Move to fresh air; seek medical aid if symptoms persist.

-

Accidental ingestion: Do not induce vomiting; seek urgent medical care.

-

Summary

Potassium Carbonate (K₂CO₃) is a highly functional, white, water-soluble alkaline salt used widely across industrial, food, agricultural and chemical sectors. With strong alkalinity, high solubility and stability, it remains an indispensable raw material for glass production, detergents, fertilisers, food processing and more.

If you are looking to source industrial or food-grade potassium carbonate, we offer reliable supply, full documentation and competitive pricing. Contact our specialists today for expert guidance and current pricing.

Potassium Chloride

Properties of Potassium ChlorideHigh solubility in water: Potassium chloride dissolves easily in water and its aqueous solutions are neutral. Salty taste: Potassium chloride tastes similar to table salt (sodium chloride). High melting point: Potassium chloride has a high melting point.

Applications of Potassium ChlorideAgricultural industry: Potassium fertilizer: Potassium chloride is one of the most important sources of potassium for plants. Potassium plays a vital role in the photosynthesis process, the production of starch and sugar, the transport of nutrients, and plant resistance to diseases. Improving soil texture: Using potassium chloride helps improve soil texture and increase its fertility. Medical Industry: Treatment of Potassium Deficiency: Potassium chloride is prescribed to treat a deficiency of potassium in the blood. Potassium deficiency can cause muscle weakness, irregular heartbeat, and fatigue. Ingredient of Medicines: Potassium chloride is used as an ingredient in some medicines. Food Industry: Salt Substitute: Potassium chloride is used as a substitute for table salt in low-sodium foods. Food Additive: Used as an additive in some foods. Chemical Industry: Raw Material: Potassium chloride is used as a raw material in the production of other chemical compounds.

Importance of Potassium for the BodyPotassium is an essential element for the proper functioning of the body. It plays an important role in regulating blood pressure, nerve transmission, muscle contraction, and water and electrolyte balance. Potassium deficiency can have serious health consequences.

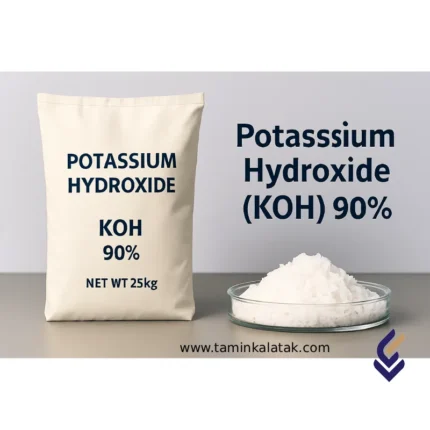

potassium hydroxide 90%

Also known as Caustic Potash or Potash Lye, Potassium Hydroxide is a highly caustic and versatile inorganic base widely used across various industries.

It is available in different grades, most commonly as 90% solid (flakes or pellets) and 45% aqueous solution.

The solid 90% grade is a white, odorless, crystalline, and strongly hygroscopic material, utilized in applications ranging from battery production to agriculture and cleaning formulations.

Chemical Structure of Potassium Hydroxide (90%)

-

Chemical Name: Potassium Hydroxide

-

Chemical Formula: KOH

-

CAS Number: 1310-58-3

-

Structure Type: Ionic – composed of K⁺ and OH⁻ ions

-

Molecular Weight: 56.11 g/mol

-

Crystal Form: White, odorless, hygroscopic crystals (absorbs moisture and CO₂ from air)

-

EC Number: 215-181-3

Physical and Chemical Properties

| Property | Description / Value |

|---|---|

| Physical State | Solid (Flakes / Pellets) – White |

| Purity | ≥ 90% (Industrial Grade) |

| Density (20°C) | 2.12 g/cm³ |

| Melting Point | 360°C (partial decomposition at higher temperatures) |

| Boiling Point | 1320°C (decomposes before complete vaporization) |

| pH (1% solution, 25°C) | 13.5 – 14 |

| Solubility in Water (20°C) | ~1100 g/L – Highly exothermic dissolution |

| Reaction with Water | Strongly exothermic |

| Solubility in Ethanol | High (unlike NaOH) |

| Vapor Pressure | Zero (non-volatile) |

Applications

1. Detergent and Cleaning Industry

-

Used in the manufacture of liquid dishwashing detergents and potassium-based soaps.

-

Serves as a milder alternative to Sodium Hydroxide (NaOH) in specific cleaning formulations.

2. Food Industry (E525 – Food Grade)

-

Employed as a pH regulator and food additive under code E525.

-

Used for softening olives, preparing alkaline beverages, and food processing under controlled conditions.

3. Chemical Industry

-

Raw material for potassium compound synthesis, including K₂CO₃, K₃PO₄, and other derivatives.

-

Applied in the production of alkaline batteries and chemical intermediates.

4. Agriculture

-

Used in alkaline nutrient solutions, fertilizer production, and pest control formulations.

-

Provides an available source of potassium for specialized agrochemical formulations.

5. Metallurgy and Battery Manufacturing

-

Functions as an electrolyte in Nickel-Cadmium (Ni-Cd) and Nickel-Metal Hydride (Ni-MH) batteries.

-

Acts as a metal surface cleaner and desulfurization agent.

Advantages

✅ Stronger base compared to Sodium Hydroxide in certain reactions

✅ Rapid and complete solubility in water and alcohol

✅ Ideal for processes requiring potassium ions (K⁺)

✅ Convenient to handle, transport, and store in solid form

Limitations

⚠️ Higher cost compared to NaOH

⚠️ Highly corrosive to skin, eyes, and light metals

⚠️ Strongly hygroscopic – requires moisture-proof packaging and dry storage

⚠️ Exothermic reaction with water – may cause splashing and thermal burns

Safety and Handling

-

GHS Classification: H314 – Causes severe skin burns and serious eye damage (Skin Corr. 1A)

-

Required PPE: Chemical-resistant gloves, safety goggles, face shield, and dust mask

-

Skin/Eye Contact: Rinse immediately with plenty of cold water for at least 15 minutes and seek medical attention

-

Reaction with Water: Highly exothermic – risk of splashing or sudden boiling

-

Storage Conditions: Store in a dry, cool, and well-ventilated area away from moisture and CO₂ exposure

-

Packaging Options: 25 kg laminated bags, sealed HDPE drums, or metal containers

-

Chemical Incompatibilities: Strong acids, light metals (e.g., aluminum, zinc), and chlorinated organic compounds

Summary

Potassium Hydroxide (KOH) is an essential alkaline compound used in numerous industrial sectors such as detergents, batteries, fertilizers, food processing, and chemical synthesis.

Its strong basicity, high solubility, and chemical reactivity make it a critical raw material in both industrial and laboratory-scale processes.

Potassium Nitrate

Physical and chemical properties of potassium nitrateSolubility: It dissolves well in water. Strong oxidizer: Potassium nitrate is a strong oxidizer and can cause violent reactions when combined with combustible materials. Hygroscopic: It absorbs moisture from the air. Thermal stability: It is stable up to a certain temperature but decomposes at higher temperatures.

Potassium nitrate applicationsFertilizer: Potassium nitrate is used as an important source of nitrogen and potassium in chemical fertilizers. Explosives: It is one of the main components of gunpowder and is also used in the production of other explosives. Food industry: It is used as a food preservative and in some food production processes. Pharmaceuticals: It is used as an excipient in some drugs. Glass industry: Used in the production of special glasses. Other applications: Used in various industries such as the production of fire retardants, metal plating, and the production of colored glass.

Safety tips when working with potassium nitrateStrong oxidizer: Avoid direct contact of potassium nitrate with combustible materials. Work environment: Work in a well-ventilated environment. Protective equipment: Use gloves, safety glasses, and a mask. Storage: Store in closed containers in a cool, dry place.

Potassium Persulfate

Properties and characteristicsStrong oxidizing power: The most important property of potassium persulfate is its very strong oxidizing power. This substance is able to oxidize many compounds. Stability at room temperature: Potassium persulfate is stable at room temperature and can be easily stored. Low moisture absorption: This compound absorbs moisture in very small amounts. Acidic aqueous solution: An aqueous solution of potassium persulfate has acidic properties.

Potassium persulfate applicationsInitiation of polymerization reactions: One of the most important uses of potassium persulfate is as a polymerization initiator in the production of various polymers such as synthetic rubber, polytetrafluoroethylene, and polyacrylamide. Bleach: Due to its strong oxidizing properties, potassium persulfate is used as a bleach in various industries. Oxidizing agent in chemical reactions: It is used as an oxidizing agent in many chemical reactions. Metal surface cleaner: It is used to clean metal surfaces from oxides and contaminants. food industry: It is used as a flour improver in some food production processes.

Potassium Sulfate

Key Properties of Potassium SulfateHigh solubility in water: This makes it easy to apply to plants. Source of potassium and sulfur: Potassium is essential for plant growth and development, while sulfur is crucial for protein synthesis. Neutral pH: It does not significantly affect soil pH.

Applications of Potassium SulfateAgriculture: Fertilizer: Potassium sulfate is a popular fertilizer as it provides both potassium and sulfur, essential nutrients for plant growth. It is particularly useful for crops that are sensitive to chloride, such as potatoes and tobacco. Industry: Glassmaking: It is used in the production of special types of glass. Dyeing: It is used as a mordant in dyeing textiles. Food Industry: It can be used as a food additive.

Benefits of Using Potassium Sulfate as a FertilizerImproved plant growth and development: Potassium sulfate provides essential nutrients for healthy plant growth. Increased crop yield: By improving plant health and nutrient uptake, potassium sulfate can lead to higher crop yields. Enhanced fruit quality: It can improve the quality of fruits and vegetables by increasing their size, color, and flavor. Soil health: Potassium sulfate can help improve soil structure and fertility.