PolyOxyMethylene (POM)

Key CharacteristicsHigh Stiffness and Strength: POM exhibits excellent mechanical properties, including high tensile strength, stiffness, and impact resistance. Low Friction: POM has a very low coefficient of friction, making it an excellent choice for moving parts. Dimensional Stability: POM maintains its shape and size over a wide range of temperatures and under various environmental conditions. Good Chemical Resistance: POM is resistant to many chemicals and solvents, although it can be susceptible to strong acids and bases. Fatigue Resistance: POM exhibits good resistance to fatigue, making it suitable for applications involving repeated stress.

Applications PolyoxymethyleneAutomotive: Gears, bearings, fuel system components, and other mechanical parts. Mechanical Engineering: Gears, pulleys, cams, and other moving parts in machinery. Consumer Goods: Handles, knobs, zippers, and other durable consumer products. Electrical/Electronics: Connectors, insulators, and other electrical components. Medical Devices: Surgical instruments and other medical components.

Advantages of Using POMHigh Strength and Stiffness: Excellent mechanical properties for demanding applications. Low Friction and Wear Resistance: Ideal for moving parts and applications requiring low friction. Dimensional Stability: Maintains precise dimensions over time. Good Chemical Resistance: Suitable for use in various chemical environments.

Disadvantages of POMSensitivity to Heat: POM can soften and deform at elevated temperatures. Creep: May exhibit creep under sustained loads at higher temperatures. Susceptibility to Certain Chemicals: Can be degraded by strong acids and bases. In summary, Polyoxymethylene (POM) is a high-performance engineering thermoplastic with excellent mechanical properties, low friction, and good dimensional stability. These properties make it a valuable material for a wide range of applications in various industries.

PolyOxyMethylene plastic (POM / Acetal)

StructurePolyoxymethylene (POM), also known as Acetal, is a semi-crystalline thermoplastic composed of repeating oxymethylene (-CH₂O-) units in its molecular structure. It exists in two main forms: homopolymer (POM-H) and copolymer (POM-C). The homopolymer version, such as DuPont’s Delrin®, has a highly regular and crystalline structure, providing higher mechanical strength and stiffness. The copolymer variant incorporates comonomers to reduce the risk of thermal and oxidative degradation, improving chemical resistance and thermal stability. The strong carbon-oxygen bonds in POM’s backbone contribute to its high strength, low friction, and excellent wear resistance, making it an ideal material for precision components in various industries. However, due to its highly crystalline nature, POM can be brittle under certain conditions and has limited adhesion properties, often requiring surface treatments for bonding or painting.

PropertiesPolyoxymethylene (POM), or Acetal, is a high-performance engineering thermoplastic known for its excellent mechanical strength, stiffness, and dimensional stability. It has a low coefficient of friction and high wear resistance, making it ideal for applications involving sliding or moving parts. POM exhibits good chemical resistance, particularly against solvents, fuels, and weak acids, while also having low moisture absorption, allowing it to maintain its properties in humid environments. It offers good electrical insulating properties, making it suitable for electronic components. Additionally, POM has a high degree of crystallinity, contributing to its rigidity and durability. However, it has poor resistance to ultraviolet radiation, can degrade at high temperatures, and has limited adhesion properties, requiring special treatments for bonding and painting.

Advantages

- High mechanical strength and rigidity

- Excellent wear and abrasion resistance

- Low friction, making it ideal for moving parts

- Good dimensional stability with low moisture absorption

- Strong chemical resistance to solvents, fuels, and weak acids

- Good electrical insulating properties

- Easy to machine and fabricate into precise components

Disadvantages

- Poor resistance to UV radiation, leading to degradation over time

- Limited heat resistance, typically usable below 120°C

- Can be brittle under high-impact loads

- Difficult to bond or paint without special surface treatments

- Susceptible to thermal degradation if overheated during processing

Applications

- Automotive – Fuel system components, gears, door locks, seatbelt parts

- Industrial machinery – Bearings, bushings, conveyor belt parts, rollers

- Consumer products – Zippers, buckles, eyeglass frames, knife handles

- Electronics – Switches, connectors, electrical housings

- Medical devices – Insulin pens, inhaler components, surgical instruments

- Aerospace – Lightweight gears, fasteners, interior components

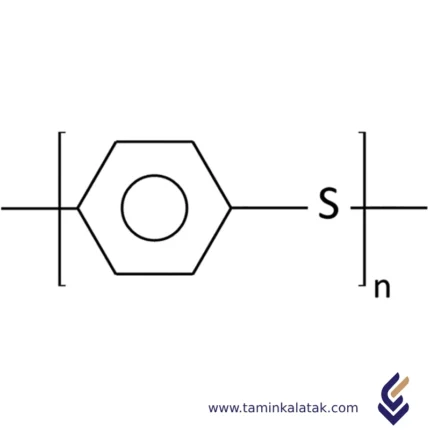

PolyPhenylene Sulfide (PPS)

StructurePolyphenylene sulfide (PPS) is a semi-crystalline polymer with a repeating backbone structure consisting of alternating benzene rings and sulfur atoms. This structure gives PPS its exceptional thermal stability, chemical resistance, and mechanical strength. The rigid benzene rings contribute to its high stiffness and dimensional stability, while the sulfur atoms provide resistance to heat and oxidation. PPS is inherently flame-retardant due to the presence of sulfur, which limits flammability and smoke generation. Depending on the polymerization method, PPS can be either linear or cross-linked, with linear PPS offering better processability and toughness. The polymer's highly ordered crystalline regions enhance its strength and resistance to solvents, making it suitable for high-performance applications in industries such as automotive, aerospace, and electronics.

PropertiesPolyphenylene sulfide (PPS) exhibits a unique combination of properties that make it suitable for high-performance applications. It has excellent thermal stability, withstanding continuous use temperatures of up to 260°C, and maintains its mechanical strength even at elevated temperatures. Its inherent chemical resistance allows it to resist strong acids, bases, and solvents without degradation. PPS also has exceptional dimensional stability due to its low moisture absorption, which prevents swelling or warping. The polymer is naturally flame-retardant, with a UL 94 V-0 rating, meaning it self-extinguishes when exposed to flame. Additionally, PPS has high stiffness and rigidity, along with good wear and fatigue resistance, making it suitable for applications requiring long-term durability. Its excellent electrical insulation properties make it a preferred material in electronic and electrical components. Depending on the grade, PPS can be reinforced with glass fibers or other fillers to further enhance its mechanical properties, ensuring it meets the demanding requirements of industries such as automotive, aerospace, and industrial manufacturing.

Applications of Polyphenylene Sulfide (PPS)

- Automotive: Fuel system components, coolant system parts, electrical connectors, under-the-hood applications.

- Aerospace: Lightweight structural components, flame-retardant electronic parts.

- Electronics & Electrical: Connectors, sockets, switches, bobbins, high-performance circuit boards.

- Industrial: Chemical processing equipment, pump components, filtration systems, gears, bearings.

- Medical: Sterilization-resistant instruments and surgical tools.

- Household Appliances & Power Tools: High-heat-resistant components, durable mechanical parts.

Advantages of PPS

- High Thermal Stability: Can withstand continuous temperatures up to 260°C.

- Excellent Chemical Resistance: Resistant to acids, bases, solvents, and fuels.

- Dimensional Stability: Low moisture absorption prevents warping or swelling.

- Flame Retardant: UL 94 V-0 rating, meaning it self-extinguishes when exposed to flames.

- High Mechanical Strength: Stiff and rigid, with good wear and fatigue resistance.

- Excellent Electrical Insulation: Suitable for high-performance electronic components.

- Low Friction & Wear Resistance: Ideal for sliding and moving parts.

Disadvantages of PPS

- Brittleness: Pure PPS is brittle and requires reinforcement for improved toughness.

- High Cost: More expensive than some other engineering plastics.

- Processing Complexity: Requires high-temperature molding, increasing production costs.

- Sensitivity to Strong Oxidizers: While chemically resistant, it can degrade in strong oxidizing environments.

PolyPropylene (PP Chemical)

Structure of Polypropylene (PP)Polypropylene (PP) is a semi-crystalline thermoplastic polymer derived from propene (C₃H₆) monomers through the polymerization process.

- Molecular Structure:

- Composed of repeating propylene units (C₃H₆) linked together in a chain-like structure.

- Exists in three main forms:

- Isotactic PP – Most commonly used, with all methyl groups (CH₃) aligned on one side of the polymer chain, resulting in high crystallinity and strength.

- Syndiotactic PP – Alternating arrangement of methyl groups, making it more flexible but less crystalline.

- Atactic PP – Random arrangement of methyl groups, leading to an amorphous structure with low strength.

- Polymerization Process:

- Polypropylene is synthesized using Ziegler-Natta catalysts or metallocene catalysts in industrial polymerization reactions.

- It is classified as a thermoplastic, meaning it can be melted and reshaped multiple times without significant degradation.

Properties of Polypropylene (PP)Polypropylene possesses a combination of mechanical, thermal, and chemical properties, making it ideal for diverse applications.

1. Mechanical Properties:

✔ High Tensile Strength – Strong yet lightweight, making it ideal for packaging and textiles. ✔ Impact Resistance – Can withstand moderate shocks and impacts. ✔ Good Elasticity & Flexibility – Suitable for films, fibers, and flexible containers.2. Thermal Properties:

✔ High Melting Point (~160°C - 170°C) – More heat-resistant than polyethylene (PE). ✔ Low Thermal Conductivity – Acts as an insulating material. ✔ Resistant to Temperature Fluctuations – Can handle both hot and cold environments.3. Chemical Properties:

✔ Resistant to Acids, Alkalis, and Solvents – Does not degrade easily when exposed to chemicals. ✔ Low Water Absorption – Maintains mechanical properties in humid environments. ✔ Good Fatigue Resistance – Ideal for repeated bending applications like hinges.4. Electrical Properties:

✔ Excellent Electrical Insulation – Used in wires, cables, and electrical components.5. Environmental Properties:

✔ Recyclable (#5 plastic code) – Can be reused in eco-friendly applications. ✔ UV Sensitivity – Can degrade when exposed to prolonged UV radiation unless treated with stabilizers.Applications of Polypropylene (PP)

- Packaging Industry

- Textile Industry

- Automotive Industry

- Medical & Healthcare Applications

- Household & Consumer Products

- Industrial Applications

Advantages of Polypropylene (PP)✔ Lightweight & Strong – Provides durability without adding extra weight. ✔ Excellent Chemical Resistance – Withstands exposure to acids, bases, and solvents. ✔ High Heat Resistance – Can be used in microwaves and hot water applications. ✔ Waterproof & Moisture-Resistant – Ideal for food packaging and textiles. ✔ Recyclable & Eco-Friendly – Can be reused, reducing plastic waste. ✔ Affordable & Cost-Effective – Inexpensive compared to other polymers. ✔ Non-Toxic & Safe – Used in medical and food-grade applications.

Disadvantages of Polypropylene (PP)✘ UV Degradation – Can become brittle when exposed to sunlight for long periods unless UV stabilizers are added. ✘ Low Impact Resistance at Low Temperatures – Can crack in extremely cold conditions. ✘ Flammability – Easily combustible and requires flame retardants for certain applications. ✘ Difficult to Paint or Glue – Requires special surface treatments for adhesion. ✘ Limited Transparency – Unlike PET, PP is not completely clear. ✘ Environmental Concerns – Though recyclable, it is not biodegradable, leading to plastic waste issues.

polypropylene (PP Textile)

StructurePolypropylene (PP) textile grade is a lightweight, semi-crystalline thermoplastic polymer composed of repeating propylene (C₃H₆) units. It is primarily found in the isotactic form, where the methyl (-CH₃) groups are aligned on the same side of the polymer chain, resulting in high crystallinity (50-70%) and enhanced mechanical properties. This structure gives polypropylene excellent tensile strength, flexibility, and durability, making it suitable for various textile applications. With a low density of around 0.90-0.91 g/cm³, it is one of the lightest synthetic fibers available. Additionally, it is highly hydrophobic, meaning it does not absorb moisture, which makes it ideal for moisture-wicking applications.

PropertiesPolypropylene (PP) textile grade is a lightweight and durable synthetic fiber with a unique combination of physical, mechanical, thermal, and chemical properties. It has a low density of around 0.90-0.91 g/cm³, making it one of the lightest synthetic fibers available, while its hydrophobic nature prevents moisture absorption, ensuring quick drying and resistance to mildew. The material exhibits high tensile strength, good elongation, and excellent abrasion resistance, making it ideal for applications requiring durability, such as ropes, carpets, and industrial fabrics. With a melting point of approximately 165°C, polypropylene offers good thermal stability, although it has a lower heat resistance compared to materials like polyester and nylon. Chemically, it is highly resistant to acids, alkalis, and organic solvents, but it has a low affinity for dyes, requiring special treatments for coloration. While it is susceptible to UV degradation, stabilizers can be added to improve its resistance to sunlight. Additionally, polypropylene is recyclable, resistant to mold and bacteria, and easy to process into various forms such as fibers and nonwoven fabrics. These properties make it a popular choice for applications in nonwoven textiles, medical fabrics, sportswear, upholstery, and filtration materials.

ApplicationsPolypropylene textile-grade fibers are widely used in various industries due to their lightweight, durability, and moisture-resistant properties. Some key applications include: Application

- Nonwoven Fabrics: Used in medical textiles, surgical masks, hygiene products (diapers, sanitary pads), and geotextiles.

- Ropes and Nets: High-strength and lightweight ropes for marine, fishing, and industrial uses.

- Carpets and Upholstery: Used in household and commercial carpets due to stain resistance and durability.

- Sportswear and Activewear: Moisture-wicking properties make it suitable for athletic clothing, socks, and thermal wear.

- Filtration Fabrics: Employed in air and liquid filtration systems due to its chemical resistance.

- Industrial Textiles: Reinforcement fabrics for automotive, construction, and packaging applications.

Advantages

- Lightweight: One of the lightest synthetic fibers, making it comfortable and cost-effective in applications.

- Moisture-Resistant: Does not absorb water, making it quick-drying and resistant to mold and mildew.

- High Tensile Strength: Strong and durable, suitable for heavy-duty textile applications.

- Chemical and Stain Resistance: Resists acids, alkalis, and organic solvents, ensuring longevity.

- Thermal Insulation: Low thermal conductivity makes it useful in cold-weather garments.

- Recyclable: Eco-friendly as it can be melted and reused.

Disadvantages

- Low Dyeability: Has a low affinity for dyes, requiring special treatments to achieve vibrant colors.

- UV Sensitivity: Prolonged exposure to sunlight can degrade the fibers unless UV stabilizers are added.

- Low Heat Resistance: Begins to soften at relatively low temperatures (~165°C), limiting its use in high-temperature applications.

Polypropylene Fiber Compounds

Structure Polypropylene Fiber Compounds

Polypropylene fiber compounds consist of a polymer matrix primarily composed of polypropylene, which is a semi-crystalline thermoplastic made from the polymerization of propylene monomers. The structure includes long molecular chains with repeating propylene units, giving the material high strength and flexibility. To enhance performance, various additives such as UV stabilizers, flame retardants, impact modifiers, and processing aids are incorporated into the polymer matrix. These compounds can be extruded and spun into fine fibers, which maintain a high degree of orientation and crystallinity, contributing to their mechanical strength, chemical resistance, and durability. The molecular alignment during fiber production improves tensile properties, making polypropylene fibers suitable for applications requiring lightweight yet strong materials. The non-polar nature of the polymer makes it resistant to moisture absorption, while the addition of stabilizers can further enhance its resistance to environmental factors such as UV radiation and oxidation. The final structure of polypropylene fiber compounds results in a material that is versatile, durable, and well-suited for applications in textiles, industrial fabrics, geotextiles, and reinforcement materials.Properties Polypropylene Fiber Compounds

Polypropylene fiber compounds possess a unique combination of properties that make them highly desirable for various applications. They are lightweight, with a low density of approximately 0.90 g/cm³, which contributes to their excellent strength-to-weight ratio. These fibers exhibit high tensile strength and durability while maintaining flexibility. Their hydrophobic nature ensures resistance to moisture absorption, preventing degradation in wet conditions. Polypropylene fibers also offer excellent chemical resistance, making them impervious to most acids, bases, and organic solvents. They have good thermal stability with a melting point between 160 and 170°C, although heat resistance can be improved with specialized additives. Electrical insulation properties are another key characteristic, as polypropylene is a non-conductive material. While naturally susceptible to UV degradation, the addition of stabilizers enhances their resistance to sunlight and weathering, making them suitable for outdoor applications. Furthermore, these fibers are resistant to microbial growth, reducing the risk of mold and mildew formation. Their low friction coefficient contributes to a smooth texture, making them comfortable for textile applications. Overall, polypropylene fiber compounds offer a balance of strength, durability, chemical resistance, and lightweight performance, making them ideal for use in textiles, industrial fabrics, geotextiles, and reinforcement materials.Applications of Polypropylene Fiber Compounds

- Textiles & Apparel: Used in nonwoven fabrics, sportswear, carpet fibers, and upholstery.

- Industrial Uses: Found in ropes, nets, packaging materials, filtration fabrics, and geotextiles.

- Construction & Infrastructure: Reinforcement fibers for concrete, roofing membranes, and insulation materials.

- Automotive: Used in seat covers, interior fabrics, and noise-dampening materials.

- Medical & Hygiene Products: Used in surgical masks, diapers, wipes, and sanitary products.

- Agriculture: Utilized in crop covers, greenhouse shading, and erosion control fabrics.

Advantages of Polypropylene Fiber Compounds

- Lightweight: Lower density than most synthetic fibers, reducing overall material weight.

- High Strength-to-Weight Ratio: Provides durability while remaining lightweight.

- Moisture Resistance: Hydrophobic nature prevents water absorption and mold growth.

- Chemical Resistance: Resistant to acids, bases, and most solvents, making it ideal for industrial and medical applications.

- Good Thermal Stability: Withstands moderate temperatures and maintains structure.

- UV and Weather Resistance: Can be enhanced with stabilizers for outdoor applications.

- Low Cost: More economical compared to other synthetic fibers like nylon and polyester.

- Eco-Friendly Options: Some grades are recyclable and can be used in sustainable applications.

Disadvantages of Polypropylene Fiber Compounds

- Low Melting Point: Less heat-resistant compared to materials like polyester or aramid fibers.

- UV Degradation: Without stabilizers, prolonged exposure to sunlight can cause brittleness.

- Limited Dyeability: Requires special dyeing techniques due to its non-polar nature.

- Low Elasticity: Lacks stretch and resilience compared to some other synthetic fibers.

- Flammability: Requires flame retardant additives for fire-resistant applications.

Polypropylene Talc Compounds

Structure

Polypropylene talc compounds consist of a polymer matrix made of polypropylene, a semi-crystalline thermoplastic, combined with finely dispersed talc particles. Talc, a naturally occurring magnesium silicate mineral, is integrated into the polymer matrix to enhance mechanical and thermal properties. The structure of these compounds features a heterogeneous phase where talc particles act as a reinforcing filler within the continuous polypropylene phase. The degree of dispersion and interfacial adhesion between the talc and polypropylene significantly influences the overall performance of the material. The crystalline regions of polypropylene provide strength and rigidity, while the amorphous regions contribute to impact resistance and flexibility. The inclusion of talc modifies the crystalline morphology, increasing stiffness, reducing shrinkage, and improving dimensional stability. The overall structure results in a composite material that offers a balance of strength, thermal resistance, and processability, making it suitable for applications that require durability and high performance under mechanical stress.Properties

Polypropylene talc compounds exhibit a unique combination of mechanical, thermal, and chemical properties that make them suitable for a wide range of applications. The addition of talc significantly enhances stiffness and rigidity, improving the material’s structural integrity and load-bearing capacity. These compounds also offer excellent dimensional stability, reducing shrinkage and warpage, which is crucial for precision-molded components. The presence of talc increases the heat deflection temperature, making the material more resistant to thermal deformation in high-temperature environments. Additionally, polypropylene talc compounds maintain good impact resistance, with the level of toughness depending on the talc content and polypropylene grade. They also demonstrate superior scratch and wear resistance, making them ideal for automotive and household applications. The material retains polypropylene’s inherent chemical resistance to acids, bases, and organic solvents, ensuring durability in harsh environments. Moreover, the addition of talc reduces the coefficient of thermal expansion, minimizing thermal expansion-related distortions. The density of the compound increases with higher talc content, generally ranging from 0.95 to 1.20 g/cm³. Overall, polypropylene talc compounds provide a balance of strength, heat resistance, and processability while maintaining cost-effectiveness for various industrial applications.Applications of Polypropylene Talc Compounds

- Automotive Industry: Used in dashboards, interior trims, bumpers, door panels, and under-the-hood components for improved stiffness and thermal resistance.

- Appliances & Consumer Goods: Found in washing machine parts, vacuum cleaner housings, kitchenware, and furniture components due to durability and scratch resistance.

- Industrial & Packaging: Utilized in rigid containers, crates, pallets, and technical parts requiring dimensional stability.

- Construction Materials: Applied in pipes, fittings, wall panels, and roofing sheets for strength and thermal stability.

- Electrical & Electronics: Used in enclosures, switchgear housings, and insulation components for mechanical durability and heat resistance.

- Medical & Healthcare: Employed in trays, medical device housings, and equipment casings due to chemical resistance and processability.

Advantages of Polypropylene Talc Compounds

- Increased Stiffness & Rigidity: Talc reinforcement significantly improves mechanical strength.

- Enhanced Dimensional Stability: Reduces shrinkage and warpage in molded parts.

- Higher Heat Deflection Temperature (HDT): Provides better resistance to thermal deformation.

- Improved Scratch & Wear Resistance: Suitable for high-contact surfaces like automotive interiors and appliances.

- Good Chemical Resistance: Maintains durability against acids, bases, and organic solvents.

- Lower Coefficient of Thermal Expansion (CTE): Minimizes expansion and contraction with temperature changes.

- Cost-Effective: Offers a balance of performance and affordability compared to high-performance engineering plastics.

- Better Processability: Allows easy molding, extrusion, and thermoforming with enhanced flow properties.

Disadvantages of Polypropylene Talc Compounds

- Reduced Impact Strength: High talc content can make the material more brittle, especially at low temperatures.

- Increased Density: The addition of talc raises the overall weight compared to pure polypropylene.

- Lower Flexibility: Higher stiffness results in reduced elongation and ductility.

- Limited UV Resistance: Requires UV stabilizers for prolonged outdoor exposure.

- Potential Processing Challenges: High talc loading may affect moldability and increase tool wear during injection molding.

Polysorbate 20 (Tween 20)

Polysorbate 20, commercially known as Tween 20, is a non-ionic surfactant widely used as an emulsifier, solubilizer, and stabilizer in various industries.

It is produced by the reaction of sorbitol with ethylene oxide and lauric acid, resulting in an amphiphilic compound capable of blending oil and water phases effectively.

Due to its excellent surface-active properties and mildness, Polysorbate 20 finds extensive applications in the cosmetic, pharmaceutical, food, and biotechnology sectors.

Chemical Structure

-

Chemical Name: Polyoxyethylene (20) sorbitan monolaurate

-

Molecular Formula: C₅₈H₁₁₄O₂₆

-

Molecular Weight: ≈ 1228 g/mol

-

Structure:

-

One sorbitol molecule (sugar alcohol backbone)

-

20 ethylene oxide units (hydrophilic component)

-

One lauric acid ester group (lipophilic component)

-

-

HLB Value: ≈ 16.7 (suitable for oil-in-water emulsions)

This unique structure provides both hydrophilic (water-loving) and lipophilic (oil-loving) properties, making it a highly effective surfactant and emulsifier.

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Appearance | Clear to light yellow viscous liquid |

| Odor | Faint or odorless |

| Solubility | Completely soluble in water, alcohol, and glycerol; insoluble in mineral oils |

| HLB Value | ~16.7 |

| pH (1% aqueous solution) | 5.0 – 7.0 |

| Melting Point | ≈ 16°C |

| Boiling Point | >100°C |

| Ionic Nature | Non-ionic |

Applications

1. Cosmetics and Personal Care

-

Functions as an emulsifier in creams, lotions, shampoos, and cleansers

-

Acts as a solubilizer for essential oils, fragrances, and active ingredients in aqueous systems

-

Reduces surface tension to improve spreadability and uniform distribution

2. Pharmaceuticals

-

Enhances the solubility of poorly soluble drugs

-

Stabilizes emulsions and suspensions

-

Used in vaccines, ophthalmic preparations, and injectables as a dispersing or wetting agent

3. Food Industry

-

Serves as an emulsifier and stabilizer in sauces, ice creams, chocolates, and dairy products

-

Improves texture, homogeneity, and prevents phase separation

4. Biotechnology and Microbiology

-

Utilized for membrane protein extraction and virus inactivation

-

Applied in cell culture and microbial preparation as a gentle detergent

Advantages

-

Non-ionic nature: chemically stable across acidic and alkaline environments

-

Excellent compatibility with a wide range of ingredients

-

Produces stable, uniform emulsions

-

Improves solubility of hydrophobic compounds

-

Acts as an anti-static agent and viscosity modifier

-

Vegan-friendly and non-comedogenic (does not clog pores)

Limitations

-

Possible trace contamination with 1,4-dioxane during manufacturing (requires purification control)

-

May cause mild skin irritation in sensitive individuals

-

Can irritate eyes or skin at high concentrations

-

Requires careful formulation control in pharmaceutical and cosmetic applications

Safety and Storage

-

Safety: Considered safe for skin and hair when used within recommended limits and industrial standards.

-

Recommended concentration: Typically 1–20% depending on the formulation.

-

Handling precautions:

-

Avoid direct eye contact.

-

In case of irritation, discontinue use and seek medical advice.

-

-

Storage conditions:

-

Store in tightly sealed containers.

-

Keep away from direct sunlight and excessive heat.

-

Maintain in a cool, dry environment (15–30°C).

-

Summary

Polysorbate 20 (Tween 20) is a versatile non-ionic surfactant known for its mildness, high water solubility, and emulsifying efficiency.

Its ability to combine oil and water phases makes it essential in cosmetics, pharmaceuticals, food formulations, and biotechnological applications.

With proper use and quality control, it provides stable, safe, and effective performance across a broad range of formulations.

Polysorbate 40 (Tween 40)

Polysorbate 40, also known by its trade name Tween 40, is a non-ionic surfactant and emulsifier produced by the reaction of sorbitan (a sugar-derived compound) with palmitic acid, followed by ethoxylation with ethylene oxide.

Thanks to its excellent emulsifying, stabilizing, and solubilizing properties, it is widely used in the food, cosmetic, pharmaceutical, and personal care industries.

Chemical Structure

-

Chemical Name: Polyoxyethylene (20) sorbitan monopalmitate

-

Molecular Formula: C₆₂H₁₂₂O₂₆

-

Average Molecular Weight: ≈ 1311 g/mol

-

Chemical Type: Non-ionic surfactant

-

HLB Value: ≈ 15.6 (suitable for oil-in-water emulsions)

-

Structure Description:

-

Hydrophilic segment: Polyoxyethylene chain

-

Lipophilic segment: Sorbitan palmitate backbone

-

This amphiphilic structure enables Polysorbate 40 to interact simultaneously with both aqueous and oily phases, forming stable and homogeneous emulsions.

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Appearance | Thick, amber-yellow to semi-transparent liquid |

| Odor | Mild, faint odor |

| Solubility | Soluble in water, ethanol, and certain organic solvents |

| Density (at 25°C) | ~1.05 g/cm³ |

| Freezing Point | –12°C to –15°C |

| pH Stability | Stable under neutral pH; resistant to oxidation |

| Thermal Stability | Stable under normal processing temperatures |

| Key Features | Enhances solubility of poorly soluble substances, prevents phase separation, provides good thermal stability |

Applications

1. Food Industry

-

Used as an emulsifier in ice cream, sauces, margarine, whipped toppings, and confectionery products

-

Improves texture, smoothness, and uniformity of formulations

-

Prevents oil-water separation and extends product shelf life

2. Cosmetics and Personal Care

-

Commonly used in creams, lotions, shampoos, and skincare formulations

-

Enhances absorption of active ingredients and stabilizes emulsions

-

Prevents graininess or phase separation in finished products

3. Pharmaceuticals

-

Functions as a surfactant and stabilizer in liquid preparations, suspensions, and injectables

-

Improves solubility of poorly water-soluble drugs

-

Helps maintain stability of temperature- or light-sensitive formulations

Advantages

-

Multifunctional: Suitable for use across food, cosmetic, and pharmaceutical industries

-

High safety profile: Approved for food and cosmetic applications (FDA & EFSA compliant)

-

Excellent emulsion stability: Produces consistent and homogeneous systems even under variable temperature conditions

-

High compatibility: Easily blends with other surfactants and additives

-

Improves product performance: Enhances shelf life, texture, and overall quality of formulations

Limitations

-

May cause mild skin or eye irritation at high concentrations

-

Possible allergic reactions in sensitive individuals

-

Decomposes under extremely high temperatures or strongly alkaline conditions

Safety and Handling

-

Regulatory Status: Considered safe for use in foods, cosmetics, and pharmaceuticals within permitted levels (FDA & EFSA approved).

-

Storage Conditions:

-

Store in tightly sealed, corrosion-resistant containers

-

Keep in a cool, dry place (20–30°C) away from direct sunlight

-

Avoid prolonged exposure to high humidity

-

-

Personal Protection (HSE):

-

Use gloves and protective eyewear during handling

-

In case of eye contact, rinse immediately with plenty of water

-

Summary

Polysorbate 40 (Tween 40) is a high-performance, non-ionic surfactant and emulsifier designed to improve product stability, solubility, and consistency.

Its balanced hydrophilic–lipophilic structure allows for efficient emulsification of oil and water phases, making it an essential ingredient in formulations requiring stability, smooth texture, and long shelf life.

By incorporating Polysorbate 40, manufacturers can achieve enhanced processing efficiency, superior product quality, and improved consumer satisfaction.

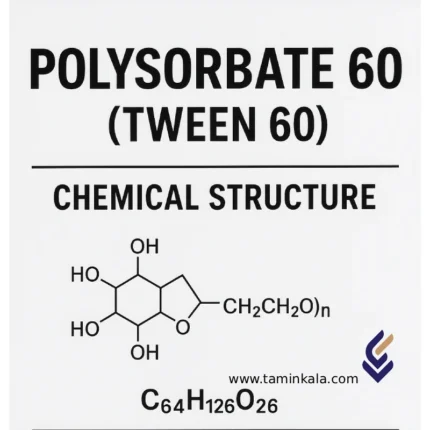

Polysorbate 60 (Tween 60)

Polysorbate 60, commercially known as Tween 60, is a non-ionic surfactant and multifunctional emulsifier produced by the reaction of sorbitan (a sugar-derived compound) with stearic acid, followed by ethoxylation with ethylene oxide.

Due to its strong emulsifying capability and ability to form stable oil-in-water (O/W) systems, it is widely used across the food, cosmetic, and pharmaceutical industries.

Chemical Structure

-

Chemical Name: Polyoxyethylene (20) sorbitan monostearate

-

Molecular Formula: C₆₄H₁₂₆O₂₆

-

Average Molecular Weight: ≈ 1315 g/mol

-

Chemical Type: Non-ionic surfactant

-

HLB Value: ≈ 14.9 (ideal for O/W emulsions)

-

Structure Description:

-

Hydrophilic portion: Polyoxyethylene chain

-

Lipophilic portion: Sorbitan stearate backbone

-

This dual (hydrophilic-lipophilic) structure makes Polysorbate 60 an ideal emulsifier for creating stable and uniform formulations.

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Appearance | Thick, pale yellow to amber liquid |

| Odor | Mild, faint odor |

| Density (at 20°C) | ~1.05 g/cm³ |

| Freezing Point | –18°C to –22°C |

| Solubility | Soluble in water, ethanol, and certain organic solvents |

| pH Stability | Stable within pH 4.5–7.5 |

| Thermal Stability | Resistant to typical processing temperatures |

| Key Feature | Enhances solubility of lipophilic substances and improves emulsion stability |

Applications

1. Food Industry

-

Used in cakes and pastries to increase volume and improve softness

-

In ice cream to prevent ice crystal formation and improve smoothness

-

In whipped toppings to stabilize foam and enhance creamy texture

-

Acts as an emulsifier in sauces, margarines, and dairy-based products

2. Cosmetics and Personal Care

-

Provides smooth and stable texture in creams and lotions

-

Used in shampoos and conditioners as a dispersing and stabilizing agent

-

Enhances permeability of active ingredients in skincare formulations

3. Pharmaceutical Industry

-

Serves as a carrier and stabilizer in liquid and semi-solid preparations

-

Improves solubility of poorly water-soluble drugs

-

Enhances stability of heat- or light-sensitive formulations

Advantages

-

Multifunctional: Suitable for a wide range of industries

-

High Safety: Approved for use within permissible limits by FDA and EFSA

-

Excellent thermal and chemical stability

-

Highly compatible with other surfactants and additives

-

Forms stable emulsions even under challenging processing conditions

Limitations

-

May cause mild irritation to skin or eyes upon direct contact

-

Possible allergic reactions in sensitive individuals, especially at high concentrations

-

Instability at very high pH levels or extreme temperatures

Safety and Handling

-

Regulatory Status: Safe for use in food, cosmetics, and pharmaceuticals according to FDA and EFSA guidelines

-

Storage Conditions:

-

Store between 20–30°C, away from direct sunlight

-

Keep in tightly closed, corrosion-resistant containers

-

Avoid long-term exposure to high humidity

-

-

HSE Precautions:

-

Use protective gloves and safety goggles during handling

-

In case of eye contact, rinse immediately with plenty of water

-

Summary

Polysorbate 60 (Tween 60) is a versatile, non-ionic surfactant and emulsifier that plays a crucial role in the food, cosmetic, and pharmaceutical industries.

Its unique balance of hydrophilic and lipophilic groups provides excellent emulsifying power, enhancing product stability, texture, and shelf life.

Selecting this ingredient in formulation development helps optimize production efficiency, improve end-product quality, and ensure greater customer satisfaction.

Polysorbate 80 (Tween 80)

Polysorbate 80, commercially known as Tween 80, is a non-ionic surfactant and powerful emulsifier produced by the reaction of sorbitan with oleic acid followed by ethoxylation with ethylene oxide.

Due to its excellent compatibility with both aqueous and oily phases, Polysorbate 80 plays a crucial role in the formulation of numerous food, pharmaceutical, and cosmetic products.

Its high clarity, chemical stability under various conditions, and relative safety have made it one of the most widely used industrial additives worldwide.

Chemical Structure of Polysorbate 80 (Tween 80)

The molecular structure of Polysorbate 80 consists of a sorbitan core linked via polyoxyethylene chains to oleic acid, a monounsaturated fatty acid.

This amphiphilic structure allows it to effectively reduce surface tension between oil and water phases and form stable emulsions.

-

Chemical Formula: C₆₄H₁₂₄O₂₆

-

CAS Number: 9005-65-6

-

Chemical Name: Polyoxyethylene (20) sorbitan monooleate

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Physical State | Thick liquid, pale yellow to amber |

| Density (at 20°C) | ~1.06 g/cm³ |

| Freezing Point | 0°C to –5°C |

| Solubility | Completely soluble in water, ethanol, and several organic solvents |

| pH Stability | Stable between pH 4–8 |

| Thermal Stability | Stable at ambient temperature |

| HLB (Hydrophilic-Lipophilic Balance) | ~15 |

Applications of Polysorbate 80 (Tween 80)

Polysorbate 80 is widely utilized across multiple industries due to its excellent emulsifying and solubilizing properties:

1. Food Industry

-

Improves texture, creaminess, and phase stability in ice creams, sauces, cakes, and dairy products

-

Prevents separation of oil and water during storage and processing

2. Pharmaceutical Industry

-

Enhances solubility of oil-soluble drugs

-

Used in the preparation of injectable solutions, vaccines, and suspensions

-

Provides stability to biologically active compounds

3. Cosmetics and Personal Care

-

Forms stable emulsions in creams, lotions, shampoos, and conditioners

-

Improves spreadability and sensory texture of formulations

4. Industrial Applications

-

Used in the formulation of lubricants, coatings, and cleaning agents

-

Acts as a wetting and dispersing agent in various chemical systems

Advantages of Polysorbate 80 (Tween 80)

-

Excellent compatibility with a wide range of hydrophilic and lipophilic substances

-

Relatively safe for food and pharmaceutical applications within approved limits

-

High solubilizing power for lipophilic compounds

-

Good thermal and chemical stability under normal processing conditions

-

Enhances product quality in terms of texture, taste, and appearance

Limitations of Polysorbate 80 (Tween 80)

-

May cause mild allergic reactions or skin sensitivity in certain individuals

-

Reduced stability under highly acidic or alkaline conditions

-

Susceptible to oxidation when exposed to high temperatures over prolonged periods

-

Limited use in organic or additive-free products

Safety and Storage

-

Storage Conditions:

-

Store in sealed containers, away from direct sunlight

-

Maintain temperature between 15–25°C

-

Avoid exposure to strong oxidizing agents

-

-

Safety:

-

Considered safe for use within the dosage limits established by international standards (FDA, EFSA, etc.)

-

Protective gloves and safety goggles should be worn during industrial handling

-

Summary

Polysorbate 80 (Tween 80) is a versatile, non-ionic surfactant and emulsifier with broad applications in the food, pharmaceutical, cosmetic, and industrial sectors.

Its unique amphiphilic nature enables it to stabilize emulsions, enhance solubility, and improve the overall performance of formulated products.

Owing to its stability, efficiency, and safety, it remains an indispensable ingredient in modern formulation science and manufacturing processes.

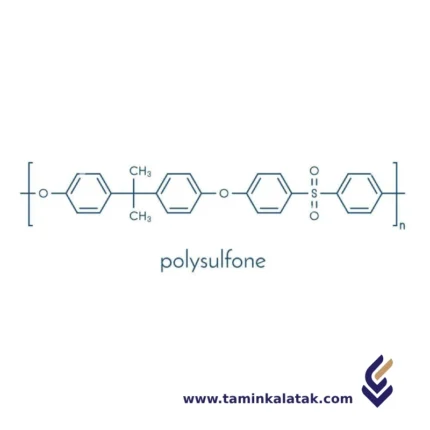

PolySulfone (PSU)

Key Features of PolySulfoneHigh Temperature Resistance: PolySulfone can withstand high temperatures without significant degradation and is well-suited for thermal environments. Excellent Chemical Resistance: Resistant to a wide range of chemicals including acids, bases, solvents, and many industrial fluids. Good Mechanical Strength: Exhibits high tensile strength, stiffness, and impact resistance. Dimensional Stability: Maintains its shape and size over a wide range of temperatures and under various environmental conditions. Hydrolytic Stability: Exhibits excellent resistance to hydrolysis (degradation by water), making it suitable for applications involving moisture or steam. Sterilizable: Can be repeatedly sterilized using methods such as autoclaving, making it suitable for medical applications.

PolySulfone ApplicationsMedical Devices: Surgical instruments, medical implants, and components for medical devices. Food Processing: Equipment for food and beverage processing such as valves, pumps, and piping. Chemical Processing: Components for chemical plants and processing equipment. Electronics: Connectors, insulators, and other electronic components. Membranes: Used in various membrane applications such as water filtration and gas separation.

Advantages of PolySulfoneHigh Temperature Resistance: Suitable for applications involving high temperatures and steam sterilization. Excellent Chemical Resistance: Ideal for use in harsh chemical environments. Hydrolytic Stability: Resistant to degradation by water and steam. Biocompatibility: Some grades of PSU are biocompatible and are suitable for medical applications.

Disadvantages of PolySulfoneHigh Cost: PSU is a relatively expensive polymer compared to other engineering plastics. Processing Challenges: PSU can be more challenging to process than some other polymers due to its high melting point.