Phenol

Properties of PhenolPhysical state: White solid Odor: Characteristic and pungent odor Solubility: Slightly soluble in water and easily soluble in organic solvents such as alcohol and ether. Acidity: Phenol is a weak acid and can react with bases. Toxicity: Phenol is a toxic and corrosive substance, and its contact with the skin, eyes, and respiratory tract can cause serious damage.

Phenol ApplicationsProduction of epoxy resins: Phenol is one of the main components in the production of epoxy resins, which are used in the manufacture of adhesives, coatings, and composites. Nylon Production: Phenol is used in the production of some types of nylon. Disinfectant production: Phenol and its derivatives are used as disinfectants and antiseptics. Dye and ink production: Phenol is used in the production of some dyes and inks. Pharmaceutical production: Phenol is used as a raw material in the production of some drugs. Detergent production: Phenol is used in the production of some detergents.

Safety and hazardsPhenol is a dangerous chemical and precautions should be taken when working with it. Phenol contact with the skin can cause burns and wounds. Inhalation of phenol vapors can cause respiratory tract irritation, dizziness, headache and even loss of consciousness. Ingestion of phenol can also cause poisoning.

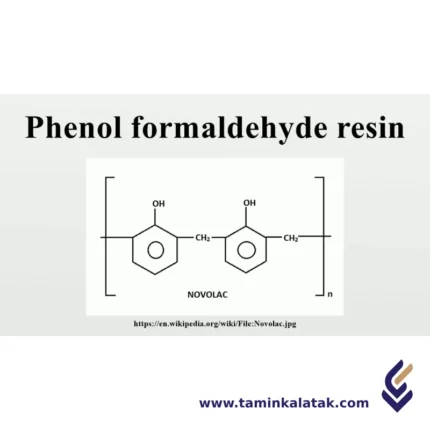

Phenol/ Formaldehyde resins (PF)

Structure Phenol-Formaldehyde

Phenol-formaldehyde resins are thermosetting polymers formed through the reaction of phenol with formaldehyde under acidic or basic conditions. The structure of these resins varies depending on the synthesis process. In the case of novolac resins, which are produced under acidic conditions with a formaldehyde-to-phenol ratio of less than one, the structure consists of linear chains of phenol units linked by methylene (-CH₂-) bridges. These resins require a curing agent, such as hexamethylenetetramine, to form a three-dimensional cross-linked network. On the other hand, resole resins, synthesized under basic conditions with an excess of formaldehyde, have a partially cross-linked structure due to the presence of hydroxymethyl (-CH₂OH) groups, which can further react upon heating to form a rigid, highly cross-linked network. This cross-linking gives phenol-formaldehyde resins their excellent thermal stability, chemical resistance, and mechanical strength, making them suitable for applications in adhesives, laminates, coatings, and molding compounds.Properties Phenol-Formaldehyde

Phenol-formaldehyde resins possess several important properties that make them highly useful in industrial applications. They exhibit excellent thermal stability, allowing them to withstand high temperatures without significant degradation. These resins also have high mechanical strength and rigidity, making them suitable for structural applications. Their chemical resistance is another key feature, as they are resistant to acids, bases, and solvents, ensuring durability in harsh environments. Additionally, phenol-formaldehyde resins have good electrical insulation properties, making them ideal for use in electrical and electronic components. They also possess inherent flame resistance, as they are self-extinguishing and do not easily catch fire. However, despite these advantages, they can be brittle and release formaldehyde, which requires controlled handling and proper ventilation during processing.Applications Phenol-Formaldehyde

- Used as adhesives and binders in plywood, particleboard, and laminates

- Employed in molding compounds for manufacturing electrical switches, knobs, and handles

- Used in coatings and varnishes for wood, metals, and electrical components

- Serves as a binder in abrasive products such as grinding wheels

- Utilized in insulation materials like fiberglass and composite structures

- Applied in foundry sand molds for metal casting

Advantages Phenol-Formaldehyde

- High thermal stability, making it resistant to heat and fire

- Excellent mechanical strength and rigidity for structural applications

- Strong adhesion properties, making it an effective bonding agent

- Good chemical resistance to acids, bases, and solvents

- Provides electrical insulation, suitable for electrical applications

Disadvantages Phenol-Formaldehyde

- Brittle nature, which can lead to cracking under stress

- Potential formaldehyde emissions, requiring controlled processing

- Limited flexibility compared to some other synthetic polymers

- Can be expensive compared to alternative resins in certain applications

Phenolic Resin

Types of Phenolic ResinPhenolic resins are divided into two main categories based on the reaction conditions and the type of catalyst: Resole: This type of resin is produced in an alkaline environment and is irreversible after curing. Resoles are used in the production of adhesives, coatings, and molding materials due to their high adhesion properties and heat resistance. Novalak: This type of resin is produced in an acidic environment and is reversible after curing. Novalaks are used as intermediate resins in the production of epoxy and phenol formaldehyde resins.

Phenolic resin propertiesHigh thermal resistance: Phenolic resins have excellent resistance to heat and flame and do not deform at high temperatures. High chemical resistance: These resins are resistant to many chemicals such as acids, bases and solvents. Good electrical insulation: Phenolic resins are good electrical insulation and are used in the manufacture of electronic components. High mechanical strength: These resins have good mechanical strength and are used in the manufacture of components with high mechanical loads.

Phenolic resin applicationsAdhesive industry: Phenolic resins are used as adhesives to bond a variety of materials such as wood, metal and ceramics. Composite industry: These resins are used as matrices in the production of fiber-reinforced composites. Molding industry: Phenolic resins are used in the production of molded parts such as billiard balls, laboratory tables and electrical insulators. Coatings industry: Phenolic resins are used in the production of protective coatings for metals and concrete. Insulation industry: These resins are used as thermal and acoustic insulation.

Phosphoric acid

Phosphorous acid

Phthalic anhydride

Phthalic Anhydride is an important aromatic chemical intermediate that appears as white crystalline flakes or powder with a pungent, irritating odor.

It is primarily used as a key raw material in the production of saturated and unsaturated polyester resins, PVC plasticizers, alkyd resins, and various pharmaceutical and dye intermediates.

Chemical Structure

Phthalic Anhydride consists of a 1,3-isobenzofuran-1,3-dione ring, obtained by dehydration of phthalic acid.

-

Molecular Formula: C₈H₄O₃

-

Structure Type: Cyclic anhydride derived from phthalic acid

-

Functional Groups: Two carbonyl groups within a fused aromatic ring

Physical and Chemical Properties

| Property | Specification |

|---|---|

| Appearance | White to transparent crystalline solid or powder |

| Density (solid, 20 °C) | ~1.53 g/cm³ |

| Melting Point | 131–132 °C |

| Boiling Point | 284–295 °C (may sublime) |

| Vapor Pressure (20 °C) | ~0.0015 mmHg (very low) |

| Solubility in Water | Slight (~0.62 g/100 g at 20 °C); higher at 100 °C (~19 g/100 g) |

| Color and Odor | Colorless to faint yellow; strong, pungent odor |

Key Advantages

-

Essential intermediate in manufacturing saturated and unsaturated polyester resins, widely used in fiberglass, coatings, and industrial paints.

-

Primary precursor for phthalate plasticizers used to enhance flexibility and durability in PVC.

-

Plays a crucial role in the synthesis of pharmaceuticals, dyes, pigments, and cosmetic raw materials.

-

High reactivity and conversion efficiency, enabling cost-effective large-scale production.

Limitations and Hazards

-

Strong irritant to skin, eyes, and respiratory system; requires controlled industrial environments.

-

Dust explosion hazard: airborne fine particles may ignite — appropriate dust control systems are essential.

-

Reacts exothermically with moisture — hydrolyzes to phthalic acid upon exposure to humidity.

-

Environmental restrictions apply in some regions due to ecological impact and emission control standards.

Applications

-

Unsaturated Polyester Resins (UPR): for FRP, composites, laminates, and industrial coatings.

-

Plasticizer Production: synthesis of phthalate esters for flexible PVC applications.

-

Paints, Adhesives, and Pigments: intermediate for alkyd resins and colorant synthesis.

-

Pharmaceuticals and Cosmetics: used in controlled synthesis of active intermediates.

-

Specialty Chemicals: manufacturing of lubricant additives, fertilizers, and functionalized industrial oils.

Safety and Handling

GHS Classification:

-

H317 – May cause an allergic skin reaction

-

H318 – Causes serious eye damage

-

H334 – May cause respiratory sensitization

Personal Protective Equipment (PPE):

-

Safety goggles or face shield

-

Chemical-resistant gloves and protective clothing

-

Respiratory protection where dust formation is possible

Storage Conditions:

-

Store in a cool, dry, and well-ventilated area

-

Keep containers tightly closed and away from moisture

-

Prevent dust accumulation and static discharge

Emergency Measures:

-

Skin/Eye Contact: Flush immediately with plenty of water and seek medical attention

-

Inhalation: Move to fresh air and consult a physician if irritation persists

-

Spillage: Avoid dust dispersion; collect dry material and dispose of safely according to local regulations

Summary:

Phthalic Anhydride (PA) is a high-purity, versatile intermediate essential in the resin, plasticizer, coating, and chemical manufacturing industries.

Its balance of reactivity, performance, and product yield makes it a critical compound in modern industrial chemistry — provided it is handled under proper safety and environmental protocols.

Physical Plasticizers (Softeners)

Other plasticizer applications

Packaging industry: Production of flexible, heat- and chemical-resistant packaging films Automotive industry: Production of car interior parts such as dashboards and seat covers Construction industry: Production of thermal and acoustic insulation, flooring and wall coverings Medical industry: Production of medical equipment such as tubes and blood bags Electronics industry: Production of electrical insulation and protective coatings

Benefits of using other plasticizers

Improving the properties of polymers: Other plasticizers allow polymers to have a wider range of properties. Reducing environmental impacts: Biodegradable plasticizers help reduce environmental pollution. Increasing the lifespan of products: Heat- and chemical-resistant plasticizers increase the lifespan of products. Reducing production costs: Some other plasticizers can reduce production costs.

Pipe Stabilizer

Why do we need pipe stabilizers?Preventing pipe damage: By preventing the movement and vibration of pipes, it prevents stress and pressure on joints and seams and increases the life of the pipe. Noise reduction: Vibration of pipes can cause annoying sounds. Stabilizers reduce these sounds by reducing vibration. Maintaining the arrangement of pipes: Stabilizers help maintain the arrangement and order of pipes and prevent problems in the plumbing system. Safety: By preventing the movement of pipes, accidents such as fluid leakage or injury to people are prevented.

Pipe Stabilizers ApplicationsConstruction Industry: Used to maintain water, gas, sewage, and heating and cooling pipes in buildings. Oil and Gas Industry: Used to maintain oil and gas transmission pipes in pipelines. Chemical Industry: Used to maintain pipes containing chemicals in factories and laboratories. Automotive Industry: Used to maintain cooling and fuel system pipes in cars.

Plastic Coating Machine & Taking-o…

Polishing Masterbatch

Structure

Polishing masterbatch is a specialized additive used in plastic processing to enhance the surface finish, gloss, and smoothness of the final product. It typically consists of a carrier resin, which is compatible with the base polymer, along with finely dispersed polishing agents, lubricants, and processing aids. The polishing agents, often inorganic materials like silica or wax-based compounds, help to reduce surface roughness and improve optical properties. Lubricants such as stearates facilitate smoother processing by reducing friction during extrusion or molding. Processing aids optimize the dispersion of the active components and ensure uniformity in the final application. The structure of polishing masterbatch allows it to be easily mixed with the base polymer, enhancing the end product’s appearance, reducing surface defects, and improving overall quality in applications like films, sheets, and molded components.Properties

Polishing masterbatch possesses several key properties that enhance the quality of plastic products. It improves surface gloss and smoothness, giving the final product a shiny and polished appearance. The masterbatch enhances scratch resistance, reducing the likelihood of surface defects and wear over time. It also provides excellent dispersion within the polymer matrix, ensuring uniform distribution and consistent performance. With good thermal stability, it can withstand high processing temperatures without degrading or causing discoloration. Additionally, it offers low friction and anti-stick properties, which facilitate easier processing and demolding. Some formulations may also include anti-static or UV-resistant properties to further enhance durability. Overall, polishing masterbatch is designed to improve the aesthetic and functional properties of plastics while maintaining compatibility with various polymer systems.Applications

- Used in plastic films to enhance gloss and smoothness for better visual appeal.

- Applied in injection molding and extrusion processes to improve the surface finish of plastic products.

- Utilized in automotive interior and exterior parts for a polished and scratch-resistant surface.

- Employed in household and consumer goods to enhance the aesthetic quality and durability.

- Used in packaging materials to improve transparency and surface quality.

- Applied in synthetic fibers and textiles to enhance smoothness and reduce friction.

Advantages

- Enhances surface gloss and smoothness, improving the overall appearance.

- Improves scratch and wear resistance, increasing the lifespan of plastic products.

- Provides uniform dispersion within the polymer matrix for consistent quality.

- Reduces surface friction, aiding in smoother processing and demolding.

- Compatible with a wide range of polymers, making it versatile in applications.

- Helps reduce production defects such as flow marks and rough surfaces.

- Can offer additional functionalities like UV resistance or anti-static properties.

Disadvantages

- May slightly alter the mechanical properties of the base polymer, such as flexibility or toughness.

- Can increase production costs due to the addition of specialized additives.

- In some cases, excessive use may affect transparency or optical clarity.

- Not all formulations are compatible with every type of plastic, requiring specific selection.

- Potential for migration over time, which may affect long-term performance in certain applications.

Poly Ether Ketones (PEK)

Structure Poly Ether Ketones

Poly Ether Ketones (PEK) have a highly rigid, semi-crystalline structure consisting of repeating aromatic rings linked by ether (-O-) and ketone (C=O) functional groups. The backbone of PEK is composed of benzophenone and diphenyl ether units, which contribute to its exceptional thermal and mechanical properties. The presence of ketone groups enhances stiffness and heat resistance, while the ether linkages provide some flexibility and processability. This unique molecular arrangement results in a polymer with high strength, excellent chemical resistance, and remarkable stability under extreme conditions. The semi-crystalline nature of PEK allows it to maintain its mechanical integrity at elevated temperatures, making it highly suitable for demanding applications in aerospace, automotive, and industrial sectors.Properties Poly Ether Ketones

Poly Ether Ketones (PEK) exhibit exceptional thermal stability, mechanical strength, and chemical resistance, making them one of the most advanced high-performance thermoplastics. They have a high melting point of approximately 360°C and can withstand continuous service temperatures above 250°C without significant degradation. PEK is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents, ensuring durability in harsh environments. Its excellent mechanical properties include high tensile strength, stiffness, and wear resistance, making it ideal for applications requiring long-term reliability. The polymer also has good electrical insulating properties, low moisture absorption, and outstanding dimensional stability, which contribute to its performance in aerospace, automotive, electronics, and medical industries. Additionally, PEK's semi-crystalline structure enhances its resistance to creep and fatigue, further increasing its suitability for high-stress and high-temperature applications.Applications of Poly Ether Ketones (PEK)

- Aerospace components such as structural parts, brackets, and insulation due to high-temperature resistance and lightweight properties.

- Automotive parts including gears, bearings, and seals where durability and wear resistance are required.

- Electrical and electronic components like connectors, insulators, and circuit boards because of excellent electrical insulation and chemical stability.

- Medical implants and surgical instruments due to biocompatibility, sterilization resistance, and mechanical strength.

- Industrial applications such as pump components, valves, and chemical processing equipment that require corrosion and high-heat resistance.

Advantages of Poly Ether Ketones (PEK)

- High thermal stability, withstanding temperatures above 250°C.

- Excellent mechanical strength, stiffness, and wear resistance.

- Superior chemical resistance against acids, bases, and organic solvents.

- Low moisture absorption and outstanding dimensional stability.

- Good electrical insulation properties, making it suitable for electronic applications.

- High resistance to creep and fatigue, ensuring long-term performance in demanding environments.

Disadvantages of Poly Ether Ketones (PEK)

- High production and processing costs compared to standard engineering plastics.

- Limited availability due to specialized manufacturing processes.

- Difficult to process because of its high melting point and specific molding requirements.

- Brittle behavior under certain conditions, which may require reinforcement for improved toughness.

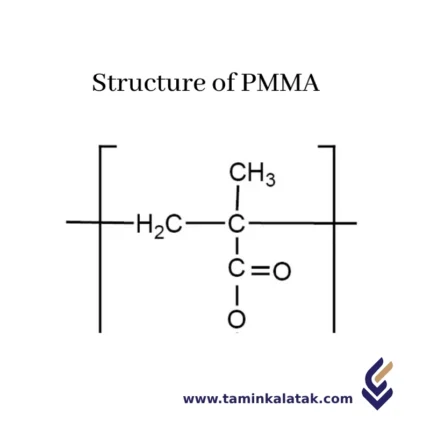

Poly Methyl Meth Acrylate (PMMA)

StructureThe structure of Poly(methyl methacrylate) (PMMA) is based on the polymerization of methyl methacrylate (MMA) monomers. Each MMA monomer consists of a methacrylate group, which contains a carbon-carbon double bond (C=C) attached to a methyl group (CH3) and a methoxycarbonyl group (COO). During polymerization, the double bonds of the MMA monomers open up, linking the monomers into long chains. This process results in a polymer backbone of repeating units, where each unit contains a carbon atom bonded to a methyl group and a carbonyl group, forming a structure like -[CH2-C(CH3)COO]-. This repeating unit gives PMMA its characteristics, including its optical clarity, rigidity, and resistance to UV degradation. The polymerization creates a linear or branched structure that is highly crystalline or amorphous, depending on the processing conditions, which contributes to PMMA's strength and transparency.

PropertiesPoly(methyl methacrylate) (PMMA) is a versatile and widely used polymer with several notable properties. It is known for its excellent optical clarity and transparency, often being used as a lightweight alternative to glass in applications such as windows, displays, and lenses. PMMA has good weather resistance, including UV stability, which helps prevent degradation, yellowing, or brittleness when exposed to sunlight. It is also relatively lightweight compared to glass, which makes it an attractive choice in applications where weight reduction is important. Additionally, PMMA has moderate chemical resistance, although it is susceptible to attack by strong acids, bases, and solvents like acetone. The material has a relatively high rigidity, making it resistant to deformation under normal conditions, though it is more brittle than other plastics such as polycarbonate. PMMA also has good electrical insulating properties and can be easily processed through methods like extrusion, injection molding, and casting. However, it is prone to scratching and requires careful handling or coating to maintain its clarity. Despite its brittleness, PMMA remains a popular choice due to its balance of clarity, weather resistance, and versatility.

Applications of Poly Methyl Meth Acrylate (PMMA)

- Optical Lenses: Used in eyeglasses, camera lenses, and optical devices due to its excellent transparency and clarity.

- Signage and Displays: Commonly used in illuminated signs, point-of-purchase displays, and advertising displays.

- Automotive: Used in automotive lighting, such as headlights and tail lights, and in the production of interior and exterior parts.

- Aerospace: Applied in aircraft windows, cockpit covers, and light fixtures for its light weight and optical properties.

- Construction: Used in windows, skylights, facades, and other building materials as a glass alternative due to its durability and weather resistance.

- Medical: Used in intraocular lenses (IOLs), bone cement, and other medical devices for its biocompatibility and clarity.

- Aquarium Panels: Popular in large aquariums and tanks as a transparent, lightweight alternative to glass.

- Furniture: Applied in the production of furniture, particularly in modern or minimalist designs for tables, chairs, and partitions.

Advantages of Poly Methyl Meth Acrylate (PMMA)

- High Transparency: PMMA is highly transparent, making it an excellent choice for optical and display applications.

- Lightweight: PMMA is significantly lighter than glass, which makes it easier to handle and install, reducing overall weight in many applications.

- UV and Weather Resistance: PMMA has strong UV resistance, preventing yellowing and degradation when exposed to sunlight, making it suitable for outdoor applications.

- Good Chemical Resistance: It is resistant to many common chemicals and environmental factors, which makes it durable in a wide range of conditions.

- Ease of Processing: PMMA can be easily processed through various methods such as extrusion, injection molding, and casting, allowing for flexibility in design.

- Versatile: It can be used in a wide range of industries, from medical and aerospace to consumer products, showcasing its broad utility.

Disadvantages of Poly Methyl Meth Acrylate (PMMA)

- Brittleness: PMMA is more brittle compared to other plastics like polycarbonate, which makes it prone to cracking or breaking under impact.

- Scratch Sensitivity: It is more easily scratched than other materials, which can degrade its appearance and clarity over time.

- Chemical Sensitivity: While it has good chemical resistance, PMMA can still be affected by strong acids, bases, and some solvents like acetone.

- Low Impact Resistance: PMMA is less impact-resistant than other materials like polycarbonate, making it less suitable for high-stress applications.

- Limited Flexibility: PMMA is relatively rigid and can be prone to shattering under stress, which limits its use in applications that require flexibility or higher durability.