Manganese Sulfate

Importance of Manganese for PlantsManganese is an essential micronutrient for plant growth. This element plays an important role in the process of photosynthesis, cellular respiration, and enzyme production. Manganese deficiency in plants causes symptoms such as yellowing of leaves, reduced growth, and reduced crop yield.

Applications of Manganese SulfateAgricultural fertilizer: Manganese sulfate is used as a micronutrient fertilizer to improve soils that are deficient in manganese. This fertilizer is produced in powder or granular form and added to the soil. Chemical industry: Manganese sulfate is used as a raw material in the production of other manganese compounds such as manganese dioxide. Dyeing industry: Used in the dyeing industry to stabilize colors. Battery industry: Used in the production of dry batteries. Pharmaceutical industry: Used as a supplement in some drugs.

Benefits of using manganese sulfateIncreasing crop yield: Providing plants with the manganese they need increases the yield and quality of agricultural products. Improving crop quality: Manganese plays a role in improving the color, taste, and size of fruits. Increasing plant resistance: Plants that have sufficient manganese are more resistant to diseases and pests. Improving soil structure: Manganese sulfate helps improve soil structure and increase its permeability.

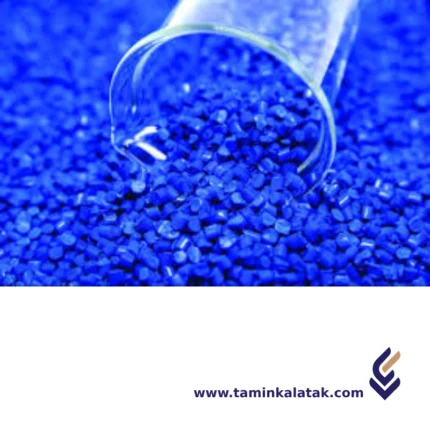

Masterbatch Anti algae and moss

StructureThe structure of an anti-algae and moss masterbatch consists of a polymer carrier, biocidal agents, UV stabilizers, and dispersing aids. The polymer carrier, typically made of polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC), ensures compatibility with the final plastic product and allows for easy incorporation during manufacturing. Biocidal agents are the active components that prevent the growth of algae, moss, and fungi by disrupting their cellular processes or inhibiting their ability to thrive on the plastic surface. UV stabilizers are often included to protect the plastic from ultraviolet radiation, which can accelerate degradation and create conditions favorable for microbial growth. Dispersing aids help evenly distribute the active ingredients throughout the plastic matrix, ensuring consistent protection over time. This carefully formulated combination helps extend the lifespan of plastic products exposed to moisture and outdoor environments while maintaining their aesthetic and functional properties.

PropertiesAnti-algae and moss masterbatch exhibits several key properties that enhance the durability and performance of plastic products in outdoor and high-moisture environments. It possesses strong antimicrobial and biocidal activity, effectively preventing the growth of algae, moss, fungi, and other microorganisms on plastic surfaces. The masterbatch is highly weather-resistant, with the ability to withstand prolonged exposure to sunlight, humidity, and rain without losing its effectiveness. It is often formulated with UV stabilizers to prevent degradation caused by ultraviolet radiation, ensuring long-term protection and maintaining the integrity of the plastic. The dispersion of active agents within the polymer matrix is uniform, allowing consistent performance across the entire product. It is also chemically stable, meaning it does not easily leach out or degrade under normal usage conditions. Additionally, it is compatible with various thermoplastic materials, such as polyethylene, polypropylene, and PVC, making it suitable for a wide range of applications, including roofing materials, outdoor furniture, agricultural films, and drainage systems.

Applications

-

- Agriculture: Used in greenhouse films, mulch films, and irrigation pipes to prevent algae growth.

- Construction: Applied in roofing sheets, tiles, drainage pipes, and water tanks to inhibit moss formation.

- Marine Industry: Helps reduce biofouling on boats, docks, and marine equipment.

- Textile Industry: Used in synthetic outdoor fabrics and geotextiles to prevent microbial degradation.

- Packaging Industry: Applied in food packaging, beverage containers, and water storage units to minimize contamination.

Advantages

-

- Prevents algae and moss growth, extending product lifespan.

- Reduces maintenance and cleaning costs.

- Enhances aesthetic appeal by preventing discoloration and surface damage.

- Improves material durability by protecting against microbial degradation.

- Available in eco-friendly formulations.

- Compatible with various plastic polymers like PE, PP, and PVC.

Disadvantages

-

- Increases production costs due to specialized additives.

- Some formulations may have environmental impacts, especially in aquatic ecosystems.

- Effectiveness may decrease over time as active ingredients degrade.

- Subject to regulatory restrictions depending on the biocides used.

- May affect the recyclability of plastic materials.

Masterbatch Anti fungus and mold

StructureA Masterbatch anti-fungus and mold formulation typically consists of a polymer carrier, such as polyethylene or polypropylene, which acts as a base resin to evenly distribute the additives throughout the material. The key components are the active anti-fungal and anti-mold agents, which include biocides, fungicides, and anti-microbial agents that inhibit the growth of fungi, mold, and bacteria. These can include chemicals like zinc pyrithione, silver-based compounds, or organosulfur agents. To enhance the processing and performance, fillers such as calcium carbonate or silica may be added, along with stabilizers like UV stabilizers, antioxidants, or light stabilizers to maintain the longevity of the masterbatch. Additionally, processing aids such as lubricants and dispersing agents are often incorporated to improve the flow and dispersion of the ingredients during manufacturing. In some cases, surfactants or pigments might be included to optimize the dispersion and give the product color, though this is less common for anti-fungal and mold masterbatches. These masterbatches are then mixed into the final product, such as plastics or coatings, to provide effective protection against mold and fungal growth.

PropertiesMasterbatch anti-fungus and mold possesses several key properties that make it effective in preventing microbial growth in plastic and polymer-based materials. It provides strong antifungal and antimicrobial protection by inhibiting the growth of mold, mildew, and bacteria, ensuring long-term durability and hygiene of the final product. The formulation is designed for excellent dispersion within the base polymer, allowing uniform distribution of active agents. It is highly stable under various environmental conditions, including high temperatures and UV exposure, preventing degradation over time. Many formulations are non-toxic and comply with regulatory safety standards, making them suitable for applications in packaging, medical devices, and consumer goods. Additionally, these masterbatches maintain the mechanical properties of the base polymer, ensuring that strength, flexibility, and appearance remain unaffected. They are also compatible with a wide range of polymers such as polyethylene, polypropylene, and polystyrene, offering versatility in application. Some variations include moisture-resistant and weatherproof properties, making them ideal for both indoor and outdoor use.

Applications

- Used in plastic packaging to prevent mold growth on food and consumer goods

- Incorporated into medical devices and equipment to ensure hygiene and reduce microbial contamination

- Applied in household products such as plastic containers, furniture, and flooring to prevent fungal damage

- Used in automotive interiors to prevent mold buildup in humid conditions

- Integrated into construction materials like PVC pipes, wall panels, and insulation for long-term mold resistance

- Employed in textiles and synthetic fibers to enhance durability and cleanliness

- Added to coatings and paints to protect surfaces from fungal and bacterial growth

- Utilized in agricultural films and greenhouse materials to minimize mold-related crop damage

Advantages

- Provides long-lasting antifungal and antimicrobial protection

- Helps in extending the lifespan of plastic materials by preventing microbial degradation

- Reduces health risks associated with mold exposure, particularly in medical and food-related applications

- Compatible with a wide range of polymers and processing methods

- Maintains the mechanical and aesthetic properties of the base material

- Some formulations are non-toxic and environmentally friendly

- Enhances hygiene and safety in various industries, including food, healthcare, and construction

Disadvantages

- May increase production costs due to the addition of specialized additives

- Some formulations may have regulatory restrictions for food contact or medical use

- Prolonged exposure to high temperatures and UV radiation can cause reduced effectiveness over time

- The presence of antimicrobial agents may lead to resistance development in microorganisms

- Requires precise formulation and dosage to avoid affecting the physical properties of the final product

Medicinal lithium carbonate

Lithium Carbonate (Li₂CO₃) is an inorganic compound widely used in psychiatry and pharmaceutical formulations as a mood stabilizer.

It plays a crucial role in the treatment of bipolar disorder, manic depression, and mood fluctuations, helping regulate neurotransmitter activity and stabilize emotional balance.

Chemical Structure and Composition

-

Chemical Formula: Li₂CO₃

-

Molecular Weight: 73.89 g/mol

-

Molecular Structure: Composed of two lithium ions (Li⁺) and one carbonate ion (CO₃²⁻)

-

CAS Number: 554-13-2

-

Grade: Pharmaceutical / API (≥99.5% purity)

Lithium Carbonate is an ionic compound formed from one of the lightest alkali metals.

Due to its ionic nature, it dissociates partially in aqueous media and demonstrates controlled solubility, which is essential for its pharmacokinetic behavior.

Physical and Chemical Properties

| Property | Specification |

|---|---|

| Appearance | White powder or colorless crystals |

| Density | ~2.11 g/cm³ |

| Melting Point | ~723°C |

| Solubility in Water | Slightly soluble (~1.3 g/L at 25°C) |

| Vapor Pressure | Negligible (non-volatile at room temperature) |

| Purity (Pharma Grade) | ≥99.5% |

| Stability | Stable under normal storage conditions |

| Odor | Odorless |

Pharmaceutical Applications

Pharmaceutical Grade Lithium Carbonate is primarily used in psychiatric medicine for mood stabilization and long-term management of affective disorders.

Main therapeutic uses include:

-

Treatment of Bipolar Disorder

-

Control of manic and hypomanic episodes

-

Prevention of severe depressive phases

-

Reduction of aggressive or self-harming behavior

-

Component of sustained-release formulations for steady plasma concentration

Additionally, it is used in neuroscience research and drug development studies related to neurotransmitter regulation and neuroprotection.

Advantages

-

Proven clinical efficacy in stabilizing mood and preventing relapse

-

Long-term maintenance therapy effectiveness

-

Reduces hospitalization rates in bipolar patients

-

Cost-effective compared to newer mood stabilizers

-

Backed by over 50 years of medical research and clinical experience

Limitations and Side Effects

Despite its therapeutic importance, Lithium Carbonate must be used under strict medical supervision due to potential side effects:

-

Possible tremors, weight gain, and increased thirst

-

Requires regular monitoring of serum lithium levels to avoid toxicity

-

Drug interactions with diuretics, NSAIDs, and cardiac medications

-

Contraindicated during pregnancy and lactation

-

Long-term use may affect renal and thyroid function

Safety and Storage Guidelines

-

Storage Conditions: Store in a cool, dry place, protected from moisture and direct light.

-

Handling: Follow Good Manufacturing Practices (GMP); avoid inhalation of powder.

-

Administration: Use only under medical supervision and at prescribed dosages.

-

Monitoring: Regularly assess renal and thyroid function during extended use.

-

Hydration: Ensure adequate fluid intake to prevent dehydration.

-

Avoid concomitant use with interacting drugs unless approved by a physician.

Summary

Pharmaceutical Grade Lithium Carbonate remains one of the most effective and established treatments for mood disorders, particularly bipolar disorder.

Its long-standing clinical validation, affordability, and therapeutic reliability make it a cornerstone compound in modern psychopharmacology.

Medicinal Magnesium Stearate

Specific uses of magnesium stearate in the pharmaceutical industryTablet production: Magnesium stearate is used as a lubricant and anti-caking agent in the production of compressed tablets. Capsule production: It helps improve the flowability of capsule filling powders. Pharmaceutical powder production: Magnesium stearate helps reduce the stickiness of powders and improve their flowability.

Safety tipsMagnesium stearate may cause lung irritation if inhaled for a long time. Direct contact with eyes can cause irritation. Use a mask and safety glasses when working with magnesium stearate.

Melamine

Melamine is a nitrogen-rich heterocyclic organic compound with the molecular formula C₃H₆N₆.

It consists of a 1,3,5-triazine ring substituted with three amino groups.

Due to its high nitrogen content (≈66%), melamine is a key raw material for producing melamine–formaldehyde resins, which are valued for their hardness, durability, and heat resistance.

Melamine plays an important role in various industries such as resin manufacturing, laminates, molded plastics, cement additives, and flame-retardant coatings, making it a high-demand product in the construction and chemical sectors.

Chemical Structure

-

Molecular Formula: C₃H₆N₆

-

Chemical Structure: 1,3,5-triazine ring with three amino groups at positions 2, 4, and 6

-

IUPAC Name: 1,3,5-triazine-2,4,6-triamine

-

CAS Number: 108-78-1

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Appearance | White crystalline powder or dry granules |

| Density (20°C) | 1.57 g/cm³ |

| Melting Point | 345°C (with decomposition) |

| Vapor Pressure (ambient) | Negligible (<0.01 Pa) |

| Water Solubility | 3.2 g/L at 20°C; 24 g/L at 90°C |

| Nitrogen Content | ~66% by weight |

| Thermal Stability | Decomposes at high temperatures releasing nitrogen gas, providing flame-retardant properties |

Key Advantages

-

Produces hard, scratch-resistant resins (e.g., laminates and Formica® panels)

-

Excellent resistance to heat, moisture, and impact

-

Smooth, glossy surface with long-lasting durability

-

Flame-retardant behavior due to nitrogen gas release during combustion

-

Effective flame-retardant additive in polymers and cement formulations

Limitations and Hazards

-

Toxicity in humans and animals: may cause kidney stones (especially with cyanuric acid exposure)

-

Potential liver and kidney damage with chronic exposure

-

Possible carcinogenicity observed in animal studies

-

Dust inhalation hazard: irritates skin, eyes, and respiratory tract

-

Dust explosion risk in storage or processing areas

-

Low solubility in cold water, limiting use in aqueous systems

Industrial Applications

-

Melamine–Formaldehyde Resin:

Used in MDF, decorative laminates, industrial adhesives, heat-resistant tableware, and kitchenware. -

Melamine Foam:

Applied in cleaning sponges (Magic Erasers), sound and thermal insulation materials. -

Flame Retardant Additive:

Incorporated into paints, coatings, polymers, and concrete to reduce flammability. -

Slow-Release Nitrogen Fertilizer:

Limited agricultural use due to high cost and slow decomposition rate in soil.

Safety and Handling

Main Hazards:

-

Oral toxicity: LD₅₀ (rat) ≈ 3161 mg/kg

-

Respiratory and eye irritation

-

Possible kidney damage after long-term exposure

Personal Protective Equipment (PPE):

-

N95 or FFP2 dust mask

-

Safety goggles

-

Chemical-resistant gloves

-

Protective clothing to prevent dust contact

Storage Conditions:

-

Keep in a cool, dry, well-ventilated area

-

Store away from oxidizing agents

-

Use sealed, clearly labeled containers

-

Avoid dust formation and dispersion

Emergency Measures:

-

Skin contact: Wash thoroughly with soap and water

-

Eye contact: Rinse immediately with clean water for at least 15 minutes

-

Inhalation: Move to fresh air immediately

-

Ingestion: Seek medical attention; do not induce vomiting

Melamine is an essential industrial compound known for its high nitrogen content, flame-retardant behavior, and resin-forming capability.

It remains a cornerstone material in resin production, laminates, and high-performance coatings, provided it is handled under proper safety and environmental protocols.

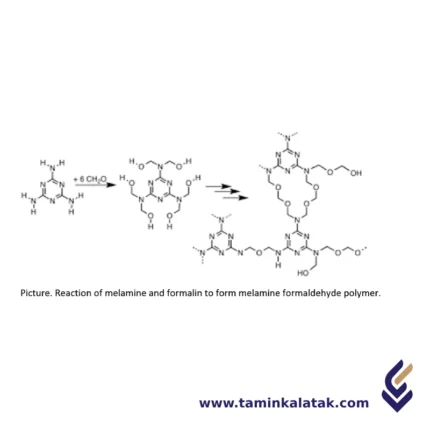

Melamine/ Formaldehyde resins (MF)

Structure Melamine/ Formaldehyde resins

Melamine-formaldehyde (MF) resins have a highly cross-linked polymeric structure formed through the polycondensation reaction of melamine and formaldehyde. Initially, melamine, a triazine-based compound with three amino groups, reacts with formaldehyde to form methylol derivatives. These methylol groups then undergo further condensation, leading to the formation of methylene and ether linkages, resulting in a rigid, three-dimensional network. This cross-linked structure is responsible for the resin's excellent thermal stability, hardness, and chemical resistance. The final polymer is a thermoset material, meaning it does not soften upon heating and maintains its structural integrity even under high temperatures and harsh environmental conditions.Properties Melamine/ Formaldehyde resins

Melamine-formaldehyde resins possess a unique combination of properties that make them highly valuable in various applications. They exhibit excellent hardness and scratch resistance, ensuring durability in high-wear environments. These resins are known for their exceptional heat resistance, withstanding elevated temperatures without losing their structural integrity. They also have good chemical and moisture resistance, making them suitable for applications exposed to water and harsh chemicals. Additionally, MF resins provide excellent electrical insulation, which is crucial for electrical and electronic components. Their ability to form a highly cross-linked network results in a rigid and dimensionally stable material, making them ideal for laminates, coatings, and molded products. Despite their many advantages, they tend to be brittle and cannot be remelted or reshaped due to their thermosetting nature.Applications of Melamine/Formaldehyde Resins (MF)

- Laminates – Used in high-pressure laminates (HPL) for furniture, countertops, and flooring.

- Molded Products – Common in dinnerware, kitchenware, electrical components, and buttons.

- Wood Adhesives – Used in plywood, particleboard, and other composite wood products.

- Surface Coatings – Provides protective and decorative finishes for paper, textiles, and metals.

- Automotive & Aerospace – Used for heat-resistant components due to its durability.

- Electrical Insulation – Applied in circuit boards and insulating materials for electrical appliances.

Advantages of Melamine/Formaldehyde Resins (MF)

- High heat resistance and retains shape under high temperatures.

- Excellent hardness, scratch resistance, and durability.

- Resistant to water, chemicals, and stains, making it suitable for harsh environments.

- Provides good electrical insulation, used in electrical components.

- Can be molded into complex shapes with a smooth finish.

Disadvantages of Melamine/Formaldehyde Resins (MF)

- Brittle nature, prone to cracking under heavy impact.

- Non-recyclable due to its thermosetting structure.

- May release small amounts of formaldehyde, which can be a health concern.

- Higher cost compared to urea-formaldehyde resins.

- Difficult to repair or modify once fully cured.

Meta acrylic acid

Meta acrylic acid

Metallic Oxides

Methacrylic acid

MethoxyPropanol

Chemical structureMethoxypropanol has an ether group (-O-) and an alcohol group (-OH) attached to a propane skeleton. The presence of these functional groups gives this substance polar properties and high solubility in water and many organic solvents.

Physical and chemical propertiesPhysical state: Colorless liquid Odor: Mild and characteristic odor Solubility: Dissolves well in water and many organic solvents. Density: Lower than water Boiling point: Relatively low Flammability: Flammable and should be stored with caution.

Applications of MethoxypropanolSolvent: Used as a solvent in the paint and resin industries, printing inks, adhesives, and coatings. Emollient: Used as an emollient in the production of cosmetic products such as lotions and creams. Intermediate in synthesis: Used to produce other chemical compounds such as esters, ethers, and resins. Cleaner: Used in some industrial and household cleaning formulations.