Magnesium Nitrate

Properties of Magnesium NitrateHigh solubility in water: This makes it easy to use in various applications. Hygroscopicity: It readily absorbs moisture from the air, making it deliquescent. Oxidizing agent: Magnesium nitrate can act as an oxidizing agent, especially at higher temperatures.

Applications of Magnesium NitrateFertilizer: It is used as a nitrogen and magnesium source in fertilizers. Pyrotechnics: It's used in fireworks and flares due to its oxidizing properties. Catalyst: It can act as a catalyst in certain chemical reactions. Drying agent: Its hygroscopic nature makes it useful as a drying agent. Laboratory reagent: It's used in various laboratory procedures.

Safety ConsiderationsWhile magnesium nitrate is a useful compound, it's important to handle it with care: Oxidizing agent: It can react strongly with reducing agents and organic materials. Health hazards: Inhalation of magnesium nitrate dust can irritate the respiratory tract.

Magnesium Stearate

Properties of Magnesium StearateHydrophobicity: Magnesium stearate is hydrophobic and therefore prevents materials from sticking to each other. Lubricity: This material acts as a lubricant and reduces friction between particles. Anti-adhesion: Magnesium stearate is used as an anti-adhesion agent in various industries. Thermal stability: This material is stable against heat.

Magnesium Stearate ApplicationsPharmaceutical Industries: Tablet and Capsule Lubricant: It is used to improve the flowability of powders and prevent materials from sticking to tablet and capsule molds. Anti-sticking: Prevents materials from sticking to pharmaceutical production machines. Food industry: Anti-sticking: Used in the production of food products such as chocolate powders, flour and sugar. Lubricant: Used in the production of chocolate and other fatty food products. Plastics industry: Lubricant: Used to improve the flowability of plastic materials in the production process. Release agent: Prevents plastic materials from sticking to molds. Cosmetics industry: Lubricant: Used in the production of cosmetics such as lipstick and eye shadow. Anti-sticking: Prevents cosmetics from sticking to packaging.

Magnesium Sulphate

Properties of Magnesium SulfateSolubility in water: Magnesium sulfate dissolves easily in water and its aqueous solutions are neutral. Hygroscopicity: This substance can absorb moisture from the air. Laxative properties: Magnesium sulfate solution has laxative properties and is used to treat constipation. Anti-inflammatory properties: Magnesium sulfate helps reduce inflammation.

Magnesium sulfate applicationsAgricultural industry: As a fertilizer to provide plants with the magnesium they need To correct acidic soils Pharmaceutical industry: As a laxative To treat magnesium deficiency in the body In some laxatives and anticonvulsants Textile industry: As a filler in fabrics To soften water in textile processes Paper industry: As a filler in paper Food industry: As a drying agent As an additive in some foods

Precautions when using magnesium sulfateOral consumption: Excessive consumption of magnesium sulfate can cause diarrhea, nausea, and vomiting. Eye contact: Contact with the eyes can cause irritation. Inhalation: Inhalation of magnesium sulfate dust can cause coughing and breathing problems.

Maleic anhydride

Maleic Anhydride is a highly important chemical intermediate widely used across multiple industries including polyester resins, coatings, pharmaceuticals, agrochemicals, and industrial additives.

It appears as a white to colorless crystalline solid with a sharp, acrid odor, and serves as a key raw material in the manufacture of unsaturated polyester resins (UPR), copolymers, and specialty chemicals.

Chemical Structure

-

Chemical Name (IUPAC): 2,5-Furandione

-

Molecular Formula: C₄H₂O₃

-

Structure Type: A reactive five-membered cyclic anhydride derived from maleic acid, exhibiting high electrophilicity — ideal for Diels–Alder, polymerization, and surface-modification reactions.

Physical and Chemical Properties

| Property | Specification |

|---|---|

| Appearance | White or colorless crystalline solid with a pungent odor |

| Molecular Weight | 98.06 g/mol |

| Density (20 °C) | ~1.48 g/cm³ |

| Melting Point | 52–56 °C |

| Boiling Point | ~202 °C at 760 mmHg (decomposes upon heating) |

| Vapor Pressure (20 °C) | ~0.16 mmHg |

| Solubility in Water (25 °C) | ~79 g/L – hydrolyzes rapidly to maleic acid |

| Stability | Moisture-sensitive; reacts exothermically with water |

| Odor | Sharp, irritating |

Key Advantages

-

Essential intermediate for unsaturated polyester resins (UPR) used in FRP composites, coatings, and laminates

-

Starting material in the synthesis of 1,4-butanediol, tetrahydrofuran (THF), γ-butyrolactone (GBL), and other specialty monomers

-

Used in surfactants, agrochemical formulations, and personal care ingredients

-

Base component for engineering copolymers such as styrene–maleic anhydride (SMA)

-

High reactivity enables efficient chemical modifications and surface treatments

Limitations and Hazards

-

Corrosive and strong irritant to skin, eyes, and respiratory tract

-

May cause skin and respiratory sensitization (H317, H334)

-

Dust may form explosive mixtures with air — proper dust control required

-

Hydrolyzes quickly in humid air to maleic acid, reducing stability

-

Requires dry, controlled storage and careful handling

Applications

-

Polyester Resins (UPR): Used in FRP, coatings, adhesives, and gel coats

-

Plasticizers & PVC Modifiers: Improves flexibility and chemical resistance

-

Pharmaceuticals: Intermediate in the synthesis of active pharmaceutical ingredients (APIs)

-

Agrochemicals & Detergents: Intermediate for surfactants, wetting agents, and additives

-

Copolymers: Base monomer for SMA, ABS modification, and compatibilizers in polymer blends

Safety and Handling Information

GHS Classification: Corrosive / Harmful

Signal Word: ⚠️ DANGER

Hazard Statements:

-

H302: Harmful if swallowed

-

H314: Causes severe skin burns and eye damage

-

H317: May cause allergic skin reaction

-

H335: May cause respiratory irritation

-

H373: May cause damage to organs through prolonged exposure

Recommended PPE:

-

Chemical-resistant gloves (nitrile or butyl rubber)

-

Protective clothing and safety goggles or face shield

-

Dust mask or approved respirator (for airborne particulates)

Storage and Stability

-

Store in a cool, dry, well-ventilated area

-

Keep containers tightly closed and protected from moisture

-

Avoid exposure to heat, sparks, or open flames

-

Use non-corrosive, moisture-proof packaging (lined drums or bags)

Emergency Measures

-

Skin/Eye Contact: Flush immediately with water for at least 15 minutes; seek medical attention

-

Inhalation: Move person to fresh air; seek medical advice if symptoms persist

-

Ingestion: Do not induce vomiting; seek immediate medical assistance

-

Spillage: Avoid dust formation; collect dry and store safely for disposal

Summary

Maleic Anhydride is a versatile and reactive intermediate essential in polyester resins, copolymers, and chemical synthesis.

Its high reactivity, industrial relevance, and broad compatibility with organic systems make it a key material in modern chemical production — provided it is handled under strict safety and storage protocols.

Maleic Anhydride Grafted ABS

Structure Maleic Anhydride Grafted ABS

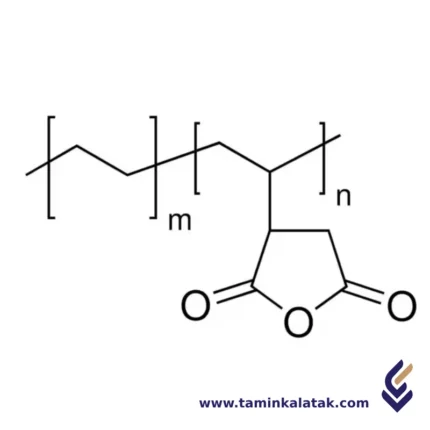

Maleic Anhydride Grafted ABS (ABS-g-MAH) consists of the standard ABS polymer backbone, which includes acrylonitrile, butadiene, and styrene, with maleic anhydride chemically grafted onto it. The grafting process typically occurs through reactive extrusion or radical polymerization, where maleic anhydride molecules attach to the butadiene or styrene segments of the ABS chain. This modification introduces polar functional groups into the otherwise non-polar ABS matrix, improving its compatibility with polar polymers, fillers, and reinforcements. The presence of maleic anhydride provides reactive sites that enhance adhesion and interfacial bonding in polymer blends and composites. While the primary structure of ABS remains intact, the grafted maleic anhydride groups contribute to increased polarity, making the material more suitable for applications requiring better dispersion of fillers, improved adhesion to coatings, and enhanced mechanical properties in polymer blends.Properties Maleic Anhydride Grafted ABS

Maleic Anhydride Grafted ABS (ABS-g-MAH) consists of an Acrylonitrile Butadiene Styrene (ABS) backbone with maleic anhydride (MAH) grafted onto it through reactive processing methods such as melt grafting or solution grafting. The structure retains the original ABS polymer framework, which comprises styrene and acrylonitrile phases dispersed in a rubbery butadiene matrix, but the addition of maleic anhydride introduces polar functional groups onto the polymer chains. The grafting process typically occurs through radical polymerization, where free radicals generated on the ABS backbone react with maleic anhydride, leading to covalent attachment. The maleic anhydride groups primarily bond to the butadiene segments or sometimes to the styrene portions, enhancing the polarity of the material. This structural modification improves compatibility with polar polymers such as polyamides and polycarbonates, increases adhesion to fillers and reinforcements, and enhances interfacial interactions in polymer blends, making ABS-g-MAH a valuable compatibilizer and adhesion promoter in various engineering applications.Applications Maleic Anhydride Grafted ABS

- Polymer Blends & Alloys – Enhances compatibility in blends like ABS/PA, PC/ABS, and ABS/PBT.

- Adhesion Promoter – Improves bonding with coatings, paints, adhesives, and metals.

- Compatibilizer in Composites – Enhances dispersion of fillers like glass fibers, talc, and carbon nanotubes.

- Automotive Industry – Used in bumpers, interior panels, and structural components requiring toughness and adhesion.

- Electronics & Electricals – Applied in enclosures, connectors, and parts requiring improved thermal and mechanical stability.

- Packaging & Consumer Goods – Improves adhesion in multilayer packaging films and functionalized plastic parts.

Advantages Maleic Anhydride Grafted ABS

- Improved Compatibility – Enhances adhesion between ABS and polar polymers or reinforcements.

- Increased Adhesion – Strong interfacial bonding with fillers, coatings, and other polymers.

- Enhanced Mechanical Properties – Better impact resistance, toughness, and thermal stability.

- Better Processability – Allows easier blending with other polymers and additives.

- Chemical Resistance – More resistant to environmental stress and certain chemicals compared to standard ABS.

Disadvantages Maleic Anhydride Grafted ABS

- Higher Cost – More expensive than standard ABS due to additional processing.

- Reduced Thermal Stability – The grafting process can sometimes lower the thermal stability of ABS.

- Possible Degradation – Maleic anhydride groups may undergo hydrolysis over time, affecting performance.

- Limited Availability – Not as widely available as standard ABS, which may affect sourcing.

Maleic Anhydride Grafted PE

Structure Maleic Anhydride Grafted PE

The structure of maleic anhydride grafted polyethylene (MAH-g-PE) consists of a polyethylene (PE) backbone with randomly grafted maleic anhydride (MAH) functional groups along the chain. The polyethylene backbone provides flexibility, hydrophobicity, and mechanical strength, while the maleic anhydride groups introduce polar functionality, improving adhesion and compatibility with polar materials. The grafting process typically occurs through a free radical mechanism, where maleic anhydride is chemically bonded to the polyethylene backbone using an initiator, such as peroxide. The resulting structure maintains the overall properties of polyethylene but gains reactive anhydride groups that can interact with hydroxyl, amine, or other polar functional groups, making it valuable for applications like compatibilization, adhesion promotion, and composite reinforcement.Properties Maleic Anhydride Grafted PE

Maleic anhydride grafted polyethylene (MAH-g-PE) exhibits a combination of properties derived from both polyethylene and maleic anhydride functional groups. It retains the flexibility, toughness, and chemical resistance of polyethylene while gaining enhanced adhesion, compatibility, and reactivity due to the grafted maleic anhydride. The presence of polar anhydride groups improves its ability to bond with polar materials such as metals, glass, polyamides, and other polar polymers, making it an effective compatibilizer in polymer blends and composites. MAH-g-PE also enhances the dispersion of fillers such as glass fibers and wood fibers in polyethylene matrices, leading to improved mechanical properties in composite materials. Additionally, it provides better wettability and surface modification capabilities, which are beneficial for applications in adhesives, coatings, and multilayer packaging. The degree of grafting and molecular weight of the polyethylene base influence the final properties, including melt flow behavior, adhesion strength, and overall performance in specific applications.Applications Maleic Anhydride Grafted PE

- Adhesive layers in multilayer films – Used in food packaging to bond polyethylene with polar materials like EVOH and polyamides.

- Compatibilizer in polymer blends – Enhances compatibility between polyethylene and polar polymers such as polyamide (PA) and polyester (PET).

- Coupling agent in composites – Improves adhesion between polyethylene and fillers like glass fibers, wood fibers, and nanomaterials.

- Surface modification – Used in coatings and primers to enhance adhesion to metals, glass, and other substrates.

- Pipe and cable coatings – Improves adhesion and durability in protective layers for pipes and electrical cables.

Advantages Maleic Anhydride Grafted PE

- Enhances adhesion to polar materials, improving compatibility in multilayer structures.

- Improves dispersion of fillers and reinforcements, leading to stronger and more durable composites.

- Retains the flexibility, toughness, and chemical resistance of polyethylene.

- Provides better surface wettability for coatings and adhesives.

- Maintains processability and can be used with standard polyethylene processing techniques.

Disadvantages Maleic Anhydride Grafted PE

- Grafting efficiency can vary, affecting performance consistency.

- May reduce the mechanical strength of the polyethylene matrix if over-grafted.

- Can introduce slight hydrophilicity, which may not be desirable in all applications.

- Higher cost compared to regular polyethylene due to additional processing and functionalization steps.

- Limited thermal stability at very high temperatures due to the presence of maleic anhydride groups.

Maleic Anhydride Grafted POE

Structure Maleic Anhydride Grafted POE

Maleic anhydride grafted polyolefin elastomer (MAH-g-POE) is a modified polymer where maleic anhydride (MAH) functional groups are chemically grafted onto a polyolefin elastomer (POE) backbone through reactive extrusion or other grafting methods. The polyolefin elastomer provides flexibility, impact resistance, and good compatibility with polyolefin-based materials, while the maleic anhydride groups introduce polar functionalities that improve adhesion, compatibility, and interfacial interactions with polar materials such as polyamides, polyesters, and fillers. The grafting process typically involves the use of an initiator, such as a peroxide, to generate free radicals that facilitate the attachment of MAH onto the POE chains. This modification enhances the polymer’s ability to act as a compatibilizer, impact modifier, or coupling agent in various applications, including toughening engineering plastics, enhancing adhesion in composite materials, and improving dispersion of fillers in polymer matrices. The degree of grafting and molecular weight of the base POE influence the final properties of the material, allowing it to be tailored for specific applications in industries such as automotive, packaging, and adhesives.Properties Maleic Anhydride Grafted POE

Maleic anhydride grafted polyolefin elastomer (POE-g-MAH) is a modified polymer known for its excellent adhesion, compatibility, and impact resistance. It retains the flexibility and toughness of polyolefin elastomers while incorporating reactive maleic anhydride groups that enhance its bonding ability with polar materials such as polyamides, polyesters, and fillers. This modification improves interfacial adhesion in composite materials, making it highly effective as a compatibilizer in polymer blends and fiber-reinforced composites. POE-g-MAH exhibits good thermal stability, chemical resistance, and weatherability, making it suitable for applications in automotive, packaging, and electrical industries. Additionally, it maintains excellent impact strength at low temperatures and provides improved processing performance due to its enhanced compatibility with other polymers.Applications of Maleic Anhydride Grafted POE (POE-g-MAH)

- Compatibilizer in polymer blends – Improves adhesion between polyolefins and polar polymers like polyamide (PA) and polypropylene (PP).

- Automotive industry – Used in bumpers, dashboards, and structural components for enhanced toughness and durability.

- Adhesives and coatings – Enhances bonding with polar substrates, improving adhesion strength.

- Thermoplastic elastomers – Used to modify elastomers for better mechanical properties.

- Wire and cable insulation – Provides improved flexibility, toughness, and weather resistance.

- Packaging materials – Enhances impact resistance and processability in multilayer films.

- Fiber-reinforced composites – Improves interfacial adhesion and toughness in composite materials.

Advantages of POE-g-MAH

- Excellent impact resistance – Maintains toughness even at low temperatures.

- Enhanced compatibility – Improves bonding between non-polar and polar polymers.

- Good thermal stability – Suitable for high-temperature applications.

- Chemical and weather resistance – Performs well in outdoor and harsh environments.

- Improves polymer blends – Enhances toughness without significantly reducing rigidity.

Disadvantages of POE-g-MAH

- Higher cost – More expensive compared to unmodified POE.

- Limited adhesion to highly polar polymers – May require further modification for specific applications.

- Lower stiffness and strength – May not match the mechanical properties of engineering plastics.

Maleic Anhydride Grafted PP

Structure Maleic Anhydride Grafted PP

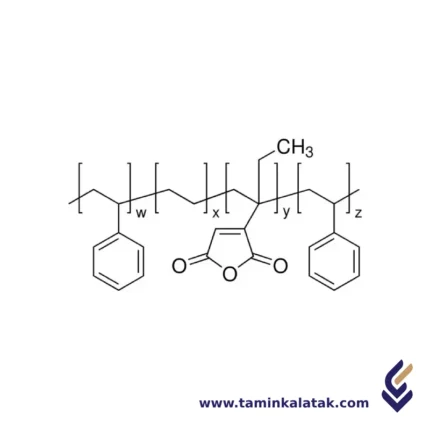

Maleic anhydride grafted polypropylene (MAH-g-PP) consists of a polypropylene backbone with randomly grafted maleic anhydride functional groups. The polypropylene provides the non-polar, hydrophobic character typical of polyolefins, while the maleic anhydride groups introduce polar functionality, allowing interaction with other polar materials. The grafting process occurs through a reactive extrusion method, where maleic anhydride and a free radical initiator, such as peroxide, create active sites on the polypropylene chains, leading to covalent bonding of the maleic anhydride units. The resulting structure retains the mechanical and thermal properties of polypropylene while enhancing its compatibility with fillers, glass fibers, polar polymers, and other materials. The grafted maleic anhydride groups, typically in a low concentration, are distributed along the polymer chain and can form hydrogen bonds or covalent interactions with hydroxyl, amine, or carboxyl functional groups in other materials, making it highly effective as a coupling agent and adhesion promoter.Properties Maleic Anhydride Grafted PP

Maleic anhydride grafted polypropylene exhibits a combination of properties from both polypropylene and maleic anhydride functionality. It retains the inherent characteristics of polypropylene, such as lightweight nature, good mechanical strength, chemical resistance, and thermal stability, while gaining enhanced compatibility with polar materials due to the presence of grafted maleic anhydride groups. This modification improves interfacial adhesion in composites, leading to better dispersion of fillers, reinforcement with glass fibers, and stronger bonding in polymer blends. It also increases surface polarity, making the material more suitable for adhesion, coatings, and compatibilization with engineering plastics like nylon and PET. The grafted maleic anhydride groups can interact with hydroxyl, amine, or carboxyl functional groups, improving overall processability and performance in applications where polypropylene alone would have poor adhesion. Additionally, it maintains good impact resistance, weatherability, and processability, making it a versatile material for various industrial applications, including automotive, packaging, and fiber-reinforced composites.Applications Maleic Anhydride Grafted PP

- Compatibilizer in polymer blends such as polypropylene with nylon (PA), polyethylene terephthalate (PET), and acrylonitrile butadiene styrene (ABS)

- Coupling agent in glass fiber-reinforced polypropylene composites for enhanced mechanical strength

- Adhesion promoter in coatings, paints, and hot melt adhesives

- Surface modifier in multilayer films and packaging to improve barrier properties and adhesion

- Filler and reinforcement enhancer for mineral-filled polypropylene composites

- Automotive components such as bumpers, dashboards, and under-the-hood parts for improved durability and impact resistance

- Pipe coatings and wire insulation for better adhesion and performance

Advantages Maleic Anhydride Grafted PP

- Enhances compatibility between non-polar polypropylene and polar materials

- Improves adhesion to fillers, fibers, and other polymers

- Increases mechanical properties such as tensile strength and impact resistance in composites

- Retains the lightweight and processable nature of polypropylene

- Improves the dispersion of fillers, leading to better structural performance

- Provides better thermal and chemical resistance compared to unmodified polypropylene

Disadvantages Maleic Anhydride Grafted PP

- Slight reduction in thermal stability due to grafting modifications

- Can introduce brittleness in some formulations if the grafting level is too high

- Processing conditions need to be carefully controlled to prevent degradation

- Higher cost compared to regular polypropylene due to the additional modification process

Maleic Anhydride Grafted PS

Structure Maleic Anhydride Grafted PS

Maleic anhydride grafted polystyrene (PS-g-MA) consists of a polystyrene backbone with randomly grafted maleic anhydride groups along the chain. The polystyrene structure is composed of repeating styrene units, each containing a benzene ring attached to an ethylene backbone. During the grafting process, maleic anhydride molecules, which have a cyclic anhydride functional group, are covalently attached to some of the styrene units through a radical reaction. This results in a modified polymer where the hydrophobic polystyrene chain incorporates polar anhydride groups, typically at irregular intervals. The anhydride functionality provides reactive sites that can undergo further chemical interactions, improving the polymer’s compatibility with polar materials, adhesion properties, and overall performance in blends and composites.Properties Maleic Anhydride Grafted PS

Maleic anhydride grafted polystyrene (PS-g-MA) exhibits a combination of properties derived from both polystyrene and the grafted maleic anhydride groups. It retains the inherent rigidity, transparency, and processability of polystyrene while gaining increased polarity and reactivity due to the anhydride functionality. The presence of maleic anhydride improves compatibility with polar polymers and fillers, enhances adhesion to various substrates, and allows for chemical modifications through reactions with nucleophiles like amines and alcohols. This modified polymer also demonstrates improved mechanical properties in certain applications, particularly in polymer blends where better interfacial adhesion leads to enhanced toughness and durability. Its thermal stability remains close to that of pure polystyrene, but processing conditions may need slight adjustments due to the reactive nature of the anhydride groups. Additionally, PS-g-MA can exhibit improved wettability and dispersion in composite materials, making it valuable in applications requiring enhanced interfacial interactions.Applications Maleic Anhydride Grafted PS

- Used as a compatibilizer in polymer blends, especially with polar polymers like polyamides and polyesters.

- Enhances adhesion in composite materials, improving bonding with fillers, fibers, and reinforcements.

- Serves as an adhesion promoter in coatings, adhesives, and surface treatments.

- Acts as a reactive modifier for polystyrene, allowing further functionalization through chemical reactions.

- Improves dispersion and interfacial adhesion in polymer nanocomposites.

- Used in impact modification of engineering plastics to enhance mechanical properties.

Advantages Maleic Anhydride Grafted PS

- Enhances compatibility between polystyrene and polar materials.

- Improves adhesion and bonding strength in composites and coatings.

- Provides reactive sites for further functionalization and chemical modifications.

- Retains the lightweight and processability of polystyrene while adding functional benefits.

- Enhances mechanical properties such as toughness and durability in polymer blends.

Disadvantages Maleic Anhydride Grafted PS

- May slightly alter the thermal and processing behavior of polystyrene.

- The grafting process can introduce variability in properties depending on the degree of grafting.

- The presence of anhydride groups can make the material more sensitive to moisture and hydrolysis.

- Cost may be higher than unmodified polystyrene due to the additional processing steps.

Maleic anhydride grafted TPE

Structure Maleic anhydride grafted TPE

Maleic anhydride grafted thermoplastic elastomer (TPE-g-MA) consists of a thermoplastic elastomer backbone with maleic anhydride groups randomly grafted onto the polymer chains. The base TPE can be a styrenic block copolymer, polyolefin-based elastomer, or other TPE types, depending on the intended application. The maleic anhydride groups introduce polar functionalities while maintaining the inherent elasticity and flexibility of the TPE. These anhydride groups are covalently bonded to the polymer backbone through a free radical grafting process, often initiated by peroxide or other radical initiators. The resulting structure has both nonpolar and polar regions, improving adhesion, compatibility with polar materials, and reactivity for further chemical modifications. This makes the material especially useful in polymer blends, composites, and adhesion-promoting applications.Properties Maleic anhydride grafted TPE

Maleic anhydride grafted thermoplastic elastomer (TPE-g-MA) retains the inherent flexibility, elasticity, and processability of the base TPE while gaining enhanced polarity and reactivity due to the grafted maleic anhydride groups. This modification improves adhesion to polar substrates, increases compatibility with polar polymers such as polyamides and polyesters, and enhances dispersion in composite materials. The material exhibits excellent mechanical properties, including good tensile strength, elongation, and impact resistance, while maintaining a soft and rubber-like feel. Its thermal stability remains similar to that of the base TPE, though the grafting process may slightly alter its flow characteristics. The maleic anhydride groups introduce reactive sites that can interact with amines, hydroxyl groups, and other nucleophiles, making it suitable for further chemical modifications. Additionally, the material provides improved resistance to environmental stress cracking and better bonding performance in over-molding applications, making it ideal for use in adhesives, coatings, automotive components, and polymer blends.Advantages Maleic anhydride grafted TPE

- Enhances adhesion to polar materials such as metals, glass, and engineering plastics.

- Improves compatibility in polymer blends, especially with polar polymers like polyamides and polyesters.

- Retains the flexibility, elasticity, and processability of the base thermoplastic elastomer.

- Provides reactive sites for further chemical modifications, such as bonding with amines or hydroxyl-containing compounds.

- Increases interfacial adhesion in composite materials, improving mechanical properties.

- Offers good resistance to environmental stress cracking and durability in demanding applications.

- Can be processed using standard thermoplastic methods like extrusion, injection molding, and blow molding.

Disadvantages Maleic anhydride grafted TPE

- Slightly altered thermal and flow properties compared to unmodified TPE.

- The grafting process can lead to some variability in material properties depending on the degree of modification.

- The presence of maleic anhydride groups may make the material more sensitive to hydrolysis in humid conditions.

- Can have a higher production cost compared to non-grafted TPE due to additional processing steps.

Applications Maleic anhydride grafted TPE

- Polymer Blends and Compatibilization: Enhances adhesion in blends of TPE with polar polymers such as polyamides, polyesters, and polycarbonates.

- Adhesives and Sealants: Used in structural bonding, pressure-sensitive adhesives, and hot-melt adhesive applications.

- Automotive Components: Improves bonding in multi-material parts, vibration damping, and soft-touch overmolding.

- Medical Devices: Provides flexibility and strong adhesion in biocompatible applications.

- Coatings and Surface Treatments: Used as an adhesion promoter for paints, coatings, and primers.

- Consumer Goods and Footwear: Enhances durability, flexibility, and adhesion in over-molded products.

- Wire and Cable Insulation: Improves adhesion to polar substrates and enhances mechanical performance.

Malic acid

Manganese carbonate

Manganese Carbonate (MnCO₃) is a key inorganic compound widely used across various industrial sectors. Naturally occurring as the mineral Rhodochrosite, it appears as a light pink to brown crystalline powder.

It serves as an essential raw material for producing manganese-based chemicals, ceramic pigments, and as a micronutrient source in agriculture.

Tak Supply Co., as a leading supplier of industrial raw materials, proudly offers high-purity Manganese Carbonate tailored to meet the diverse needs of chemical, ceramic, and agricultural industries.

Chemical Structure

Manganese Carbonate is an ionic salt composed of divalent manganese cations (Mn²⁺) and carbonate anions (CO₃²⁻).

It is insoluble in water, but readily decomposes in dilute acids, releasing carbon dioxide — a typical reaction used for its identification.

| Property | Specification |

|---|---|

| Chemical Formula | MnCO₃ |

| Molecular Weight | 114.95 g/mol |

| Appearance | Light pink to brown crystalline powder |

| Density | 3.12 g/cm³ |

| Decomposition Temperature | >200°C (decomposes to MnO + CO₂) |

| Solubility in Water | Practically insoluble |

| Solubility in Acids | Soluble in dilute mineral acids |

| CAS Number | 598-62-9 |

Industrial Applications

1. Agriculture and Fertilizer Production

Used as a micronutrient source of manganese (Mn) — essential for photosynthesis, enzyme activation, and plant growth.

Its slow-release nature makes it suitable for alkaline soils to correct manganese deficiency.

2. Ceramics, Glazes, and Pigments

Functions as a coloring agent, imparting pink, brown, or purple hues to ceramic bodies and glazes.

3. Chemical Manufacturing

A precursor in the production of manganese compounds such as manganese oxide (MnO), manganese sulfate (MnSO₄), and manganese chloride (MnCl₂).

4. Metallurgy and Electronics

Applied in the production of ferrites and magnetic materials for electronic components and as an additive in welding electrode coatings.

5. Animal Feed Additive

Serves as a nutritional supplement to supply manganese in animal feed formulations for livestock and poultry.

Key Advantages

-

Economical source of manganese for industrial and agricultural use.

-

High purity grades available for specialized chemical and electronic applications.

-

Slow and sustained release of Mn in soils, improving nutrient efficiency.

-

Versatile and compatible with multiple industrial processes.

Limitations

-

Air oxidation sensitivity: Prolonged exposure to air and moisture may oxidize MnCO₃ to manganese oxides, affecting color and purity.

-

Insoluble in water: Not suitable for liquid fertilizers or foliar applications; manganese sulfate is preferred in such cases.

-

Dust formation: Powder handling may generate dust; appropriate ventilation and PPE are recommended.

Safety and Storage Guidelines

-

Storage: Keep in cool, dry, and well-ventilated areas, away from strong acids, heat, and moisture.

Store in sealed containers or lined bags to prevent oxidation and moisture absorption. -

Personal Protection: Use dust masks, gloves, and safety goggles to avoid inhalation or contact with eyes and skin.

-

Environmental Precaution: Avoid release into drains or soil; dispose of according to local environmental regulations.

Summary

Manganese Carbonate (MnCO₃) is a versatile and cost-effective raw material essential in chemical synthesis, ceramics, metallurgy, and agriculture.

Its chemical stability, controlled solubility, and micronutrient value make it a preferred material in both industrial and agronomic applications.