Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A thermoplastic is a type of plastic polymer that becomes moldable or flexible at a certain temperature and solidifies upon cooling. This property allows it to be repeatedly softened by heating and hardened by cooling without significant chemical change.

Thermoplastic PolyOlefins (TPO)

Thermoplastic Polyolefins (TPO) are a class of polyolefin-based thermoplastic elastomers that combine the properties of polypropylene (PP), polyethylene (PE), and elastomers. They are widely used in various industries due to their durability, flexibility, chemical resistance, and ease of processing.

Structure

Thermoplastic polyolefins (TPOs) have a heterogeneous polymer structure, consisting of a semi-crystalline polypropylene (PP) matrix blended with amorphous elastomeric domains, typically ethylene-propylene-diene monomer (EPDM) or ethylene-propylene rubber (EPR). The PP component provides rigidity, thermal stability, and strength, while the elastomeric phase contributes flexibility, impact resistance, and toughness. Unlike copolymers, TPOs maintain a phase-separated microstructure, where the rubber particles are dispersed within the PP matrix rather than chemically bonded. This structure allows TPOs to remain thermoplastic, meaning they can be melted and reprocessed without undergoing permanent chemical cross-linking. Additionally, the presence of optional fillers such as talc, glass fibers, or carbon black can modify properties like stiffness and durability. The balance between the crystalline regions of PP and the amorphous elastomer phase gives TPOs their unique combination of strength, flexibility, and recyclability, making them ideal for applications in automotive parts, roofing membranes, and flexible packaging materials.

Properties

Thermoplastic Polyolefins (TPOs) possess a unique combination of mechanical, thermal, chemical, and electrical properties that make them highly versatile in various applications. Mechanically, they offer high impact resistance, good flexibility, and moderate stiffness, thanks to the combination of a semi-crystalline polypropylene (PP) matrix and elastomeric components such as ethylene-propylene rubber (EPR) or EPDM. They also exhibit excellent tear and abrasion resistance, making them durable in demanding environments. Thermally, TPOs can withstand temperatures up to 120–140°C, with a relatively low melting point (~165°C for the PP phase), allowing for easy processing via injection molding, extrusion, and thermoforming. Chemically, they are highly resistant to oils, greases, solvents, acids, and bases, and with proper stabilization, they offer good UV and weather resistance, making them suitable for outdoor applications such as automotive exteriors and roofing membranes. Additionally, TPOs have low water absorption, ensuring dimensional stability in humid conditions. Electrically, they function as good insulators, making them useful in select wire and cable applications. Their thermoplastic nature allows for melting and reshaping, making them highly recyclable and environmentally friendly compared to traditional thermoset rubbers. Moreover, TPOs are lightweight, contributing to fuel efficiency in automotive applications and reducing material costs. These combined properties make TPOs ideal for automotive bumpers, flexible packaging, consumer goods, and construction materials.

Applications of Thermoplastic PolyOlefins

- Automotive Industry:

- Bumpers and fascias

- Interior trim panels and dashboard components

- Weather seals and underbody shields

- Lightweight structural parts for fuel efficiency

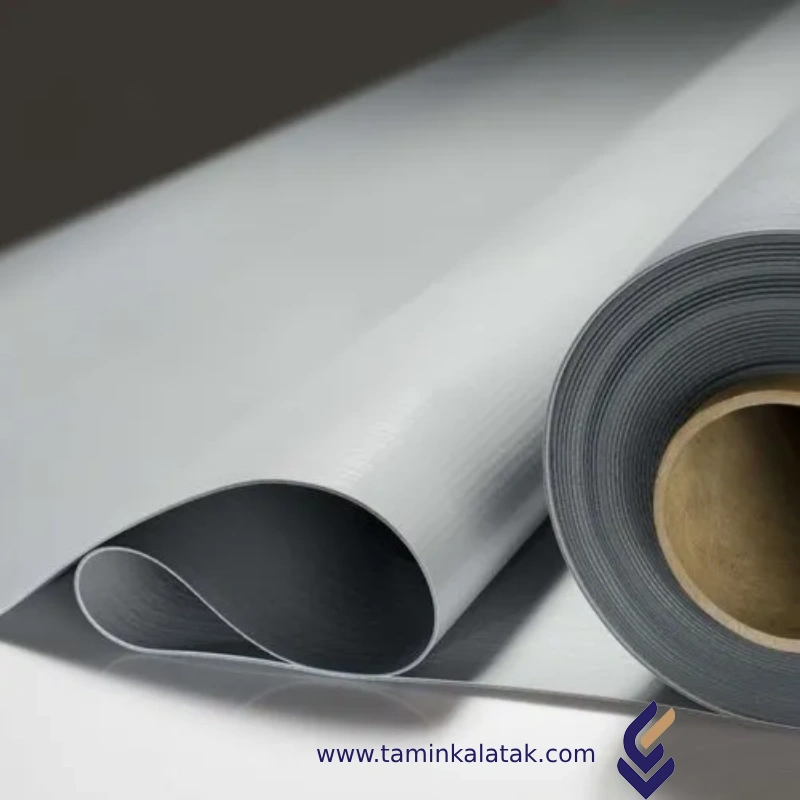

- Roofing & Construction:

- TPO roofing membranes (waterproof and UV-resistant)

- Flexible building materials and siding

- Window and door seals

- Consumer Goods:

- Sporting equipment (e.g., soft-touch grips, protective gear)

- Medical components (due to chemical resistance)

- Household items like storage bins and furniture components

- Packaging Industry:

- Rigid and flexible food containers

- Industrial packaging solutions

- Electrical & Electronics:

- Wire and cable insulation

- Protective casings for devices

Advantages of Thermoplastic PolyOlefins

High Impact Resistance – Absorbs shocks and mechanical stress effectively

Flexible Yet Durable – Balances elasticity with structural integrity

Excellent Weather & UV Resistance – Ideal for outdoor applications

Good Chemical & Water Resistance – Resists oils, solvents, and moisture

Lightweight – Reduces material costs and improves fuel efficiency in vehicles

Easy to Process & Mold – Can be injection molded, extruded, or thermoformed

Thermoplastic & Recyclable – Can be reprocessed, making it an eco-friendly choice

Cost-Effective – Lower production costs compared to thermoset rubbers

Disadvantages of Thermoplastic PolyOlefins

Lower Heat Resistance – Limited to around 120–140°C, making it unsuitable for high-heat applications

Lower Stiffness Compared to Some Plastics – May require reinforcement (e.g., glass fibers) for structural strength

Surface Finish Limitations – May require coatings or treatments for improved aesthetics

Difficult to Bond with Adhesives – Requires specialized bonding techniques due to low surface energy

Can Become Brittle in Extreme Cold – Some formulations may lose flexibility at very low temperatures

TPO

| Products | MFI (g/10 min) | Density (g/Cm3) | Process Metod | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| TPO | 0.5 to 30(measured at 230°C under a 2.16 kg load) | 0.89 to 0.92 | Injection Molding Extrusion Blow Molding Thermoforming | Bumpers, fascias, dashboard components,Weather seals and underbody protection ,Lightweight structural parts for fuel efficiency |