Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Plasticizers are chemical additives added to polymers to increase their flexibility, ductility, and processability.

Tri Octyl Tri Mellitate (TOTM)

Tri-Octyl Trimellitate (TOTM) is an organic compound primarily used as a plasticizer. It is a colorless to pale yellow liquid with a mild odor, and it belongs to the class of trimellitate esters. The chemical formula of TOTM is C24H38O4.

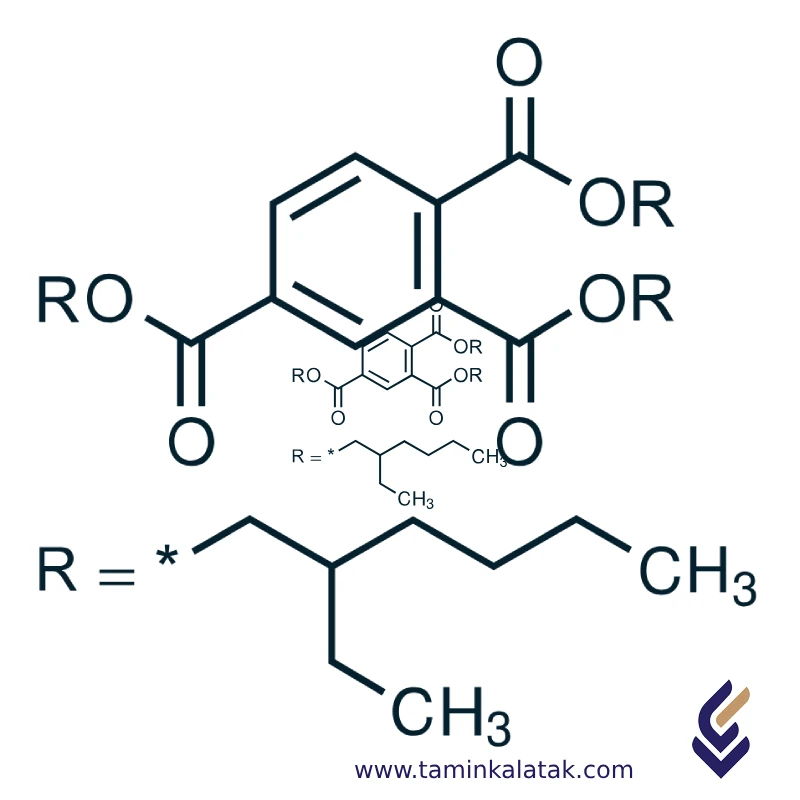

Structure

The structure of Tri-Octyl Trimellitate (TOTM) consists of a central trimellitic acid molecule, which is an aromatic dicarboxylic acid. This molecule is esterified with three octyl groups, which are derived from octyl alcohol, a long-chain alcohol. Each of the three octyl groups is attached to one of the carboxyl groups on the trimellitic acid via an ester bond. The octyl groups, with a carbon chain length of eight carbon atoms, contribute to the compound’s high molecular weight and oily texture. The result is a molecule with a large, non-polar hydrophobic character, which provides its useful properties as a plasticizer. The overall molecular formula is C24H38O4, reflecting the combination of the aromatic trimellitic structure and the three octyl ester groups.

Properties

Tri-Octyl Trimellitate (TOTM) is a colorless to pale yellow liquid with a mild odor. It has a high molecular weight and a low volatility, which contributes to its stability in various applications. Its excellent thermal stability makes it suitable for use in high-temperature environments, as it can withstand temperatures without degrading. TOTM also exhibits low toxicity and is considered less harmful to both humans and the environment compared to some other plasticizers, such as phthalates. It has good compatibility with a wide range of polymers, particularly polyvinyl chloride (PVC), where it enhances flexibility and durability. Additionally, TOTM has low migration properties, meaning it does not easily leach out of plastics, which makes it ideal for long-lasting applications like electrical cables and automotive parts. The compound also has good resistance to aging, making it a reliable choice for products exposed to harsh conditions over extended periods. Its low volatility and high flash point add to its safety in industrial applications.

Tri-Octyl Tri-Mellitate (TOTM) is a plasticizer used primarily in polymers like PVC to improve their flexibility, durability, and performance. Below are its applications, advantages, and disadvantages:

Applications of TOTM

- Plasticizer in PVC (Polyvinyl Chloride): TOTM is commonly used to improve the flexibility and processing of PVC compounds.

- Electrical Cable Insulation: It’s used in manufacturing insulation for electrical cables, offering resistance to heat, cold, and environmental factors.

- Coatings: Used in the production of durable and flexible coatings for various surfaces.

- Automotive Applications: In car interiors, particularly for making soft-touch surfaces and dashboard components.

- Medical Devices: Used in the production of flexible medical tubing and other PVC-based medical products.

- Packaging Materials: Provides flexibility to packaging films, improving their resistance to cracking.

Advantages of TOTM

- High Thermal Stability: TOTM provides excellent heat resistance, making it ideal for high-temperature applications.

- Good Electrical Insulation: Offers good electrical properties, which is particularly useful in the cable and wire industries.

- Low Volatility: TOTM has low volatility compared to other plasticizers, which reduces the likelihood of migration and volatilization over time.

- Durability: Offers long-lasting flexibility, making it suitable for products that require extended lifespans, such as electrical cables and medical devices.

- Non-Toxic: It is considered non-toxic and safer for use in medical and food-related applications when compared to other plasticizers.

Disadvantages of TOTM

- Higher Cost: TOTM is generally more expensive than other plasticizers, such as dioctyl phthalate (DOP).

- Lower Compatibility with Some Polymers: It may not be as compatible with all types of resins and can affect the processing of some materials.

- Reduced Processability: The use of TOTM may slightly reduce the processability of PVC due to its high molecular weight.

- Environmental Concerns: While safer than some other plasticizers, its environmental impact (especially in terms of biodegradability) may still be a concern.

Limited Use in Certain Applications: Its higher cost and specific application range may limit its widespread use in cheaper, high-volume manufacturing

Applications

| Applications | , , , , , |

|---|

Tri Octyl Tri Mellitate

| Products | Viscosity(cP) | Density (g/Cm³) | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|

| TOTM0 | 30-50 | 97,00 | Plasticizer in PVC (Polyvinyl Chloride) Electrical Cable Insulation Medical Devices flexible medical tubing, blood bags, Automotive Industry Coatings and Paints |