Polyvinyl chloride PVC

Polyvinyl Chloride (PVC) is one of the most widely used thermoplastic polymers in the world, produced by polymerization of vinyl chloride monomer (VCM).

Thanks to its excellent chemical resistance, adjustable flexibility, durability, and cost efficiency, PVC is used across diverse industries — from construction and electrical engineering to medical and automotive manufacturing.

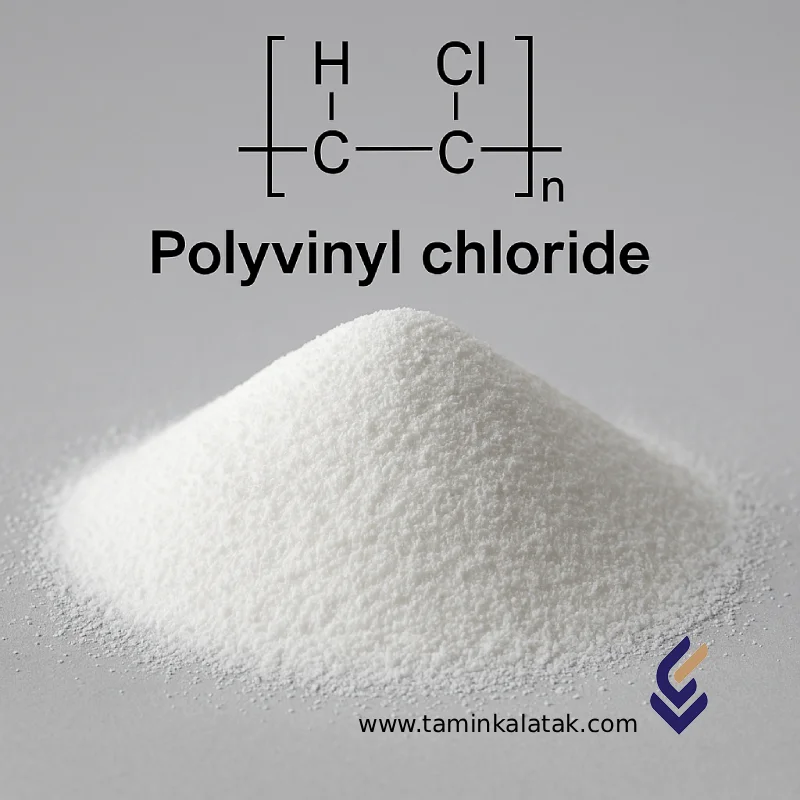

Chemical Structure and Composition

-

Chemical Formula: (C₂H₃Cl)ₙ

-

Monomer: Vinyl Chloride (CH₂=CHCl)

-

Molecular Structure: Linear chains of repeating –CH₂–CHCl– units

-

Structural Type: Amorphous thermoplastic containing chlorine (~57% by weight)

The presence of chlorine atoms enhances PVC’s chemical resistance, flame retardancy, and dimensional stability compared to other common polymers like PE and PP.

PVC is available in two main types:

-

Rigid PVC (uPVC) – high strength, used in pipes and profiles

-

Flexible PVC (Plasticized PVC) – soft and elastic, used in films and cables

Physical and Chemical Properties

| Property | Typical Value |

|---|---|

| Chemical Formula | (C₂H₃Cl)ₙ |

| Density | 1.35 – 1.45 g/cm³ |

| Melting Point | 75 – 105 °C (depending on additives) |

| Water Solubility | Insoluble |

| Solubility in Organics | Soluble in ketones, esters, and chlorinated solvents |

| Color | White or colorless (easily pigmented) |

| Chemical Resistance | Excellent resistance to acids, bases, and most solvents |

| Thermal Decomposition | Above 140 °C (releases HCl gas if overheated) |

Key Advantages

-

Cost-effective compared to other engineering plastics

-

Excellent chemical and corrosion resistance

-

Moisture-proof and resistant to microbial attack

-

Adjustable flexibility via addition of plasticizers

-

Good electrical insulation properties

-

Recyclable and compatible with sustainable manufacturing practices

Limitations

-

Sensitive to UV radiation – requires stabilizers for outdoor use

-

Thermal instability – decomposes if overheated, releasing hydrogen chloride (HCl)

-

Requires additives (stabilizers, lubricants, plasticizers) to enhance processing and durability

-

Lower impact resistance compared to some engineering thermoplastics

Main Applications of PVC

1. Construction Industry

-

Water and sewage pipes

-

Window and door profiles (uPVC)

-

Floor coverings, wall panels, roofing membranes

2. Electrical and Electronics

-

Cable and wire insulation

-

Electrical conduits and fittings

3. Packaging

-

Flexible films, shrink wraps, and transparent sheets

4. Medical Applications

-

Blood and IV bags, tubing, catheters, and medical-grade films

5. Automotive and Consumer Goods

-

Interior trims, dashboard coatings, seat coverings, and synthetic leather

Safety, Handling, and Storage

-

Storage: Keep in a cool, dry, and well-ventilated area away from direct sunlight and heat sources.

-

Handling: Ensure proper ventilation during processing to avoid exposure to fumes or dust.

-

Personal Protection: Use dust masks, gloves, and eye protection when handling powders or granules.

-

Fire Behavior: PVC is self-extinguishing due to its chlorine content but may release toxic gases (HCl) when burned.

-

Transportation: Packed in sealed, moisture-resistant bags or bulk containers under standard polymer transport regulations.

Summary

Polyvinyl Chloride (PVC) combines versatility, durability, and cost-effectiveness, making it one of the most valuable polymers in industrial applications.

Whether in rigid form for structural uses or flexible form for films and medical devices, PVC continues to play a critical role in modern materials engineering thanks to its adaptability, recyclability, and broad performance range.

Applications

| Applications | , , , |

|---|

Polyvinyl chloride PVP

| Products | Grade | Mfi (g/10 min) | Density (g/mm3) | Process Metod | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|---|

| Polyvinyl chloride PVP | |||||||

| Polyvinyl chloride PVP |