Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Engineering polymers are high-performance plastics that exhibit superior mechanical, thermal, chemical, and electrical properties compared to standard commodity plastics.

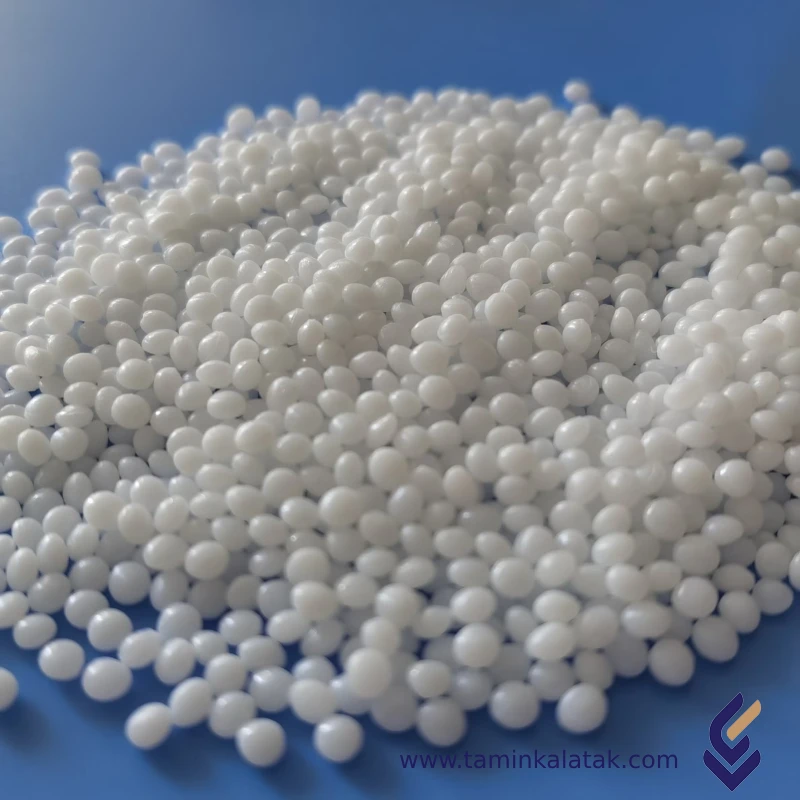

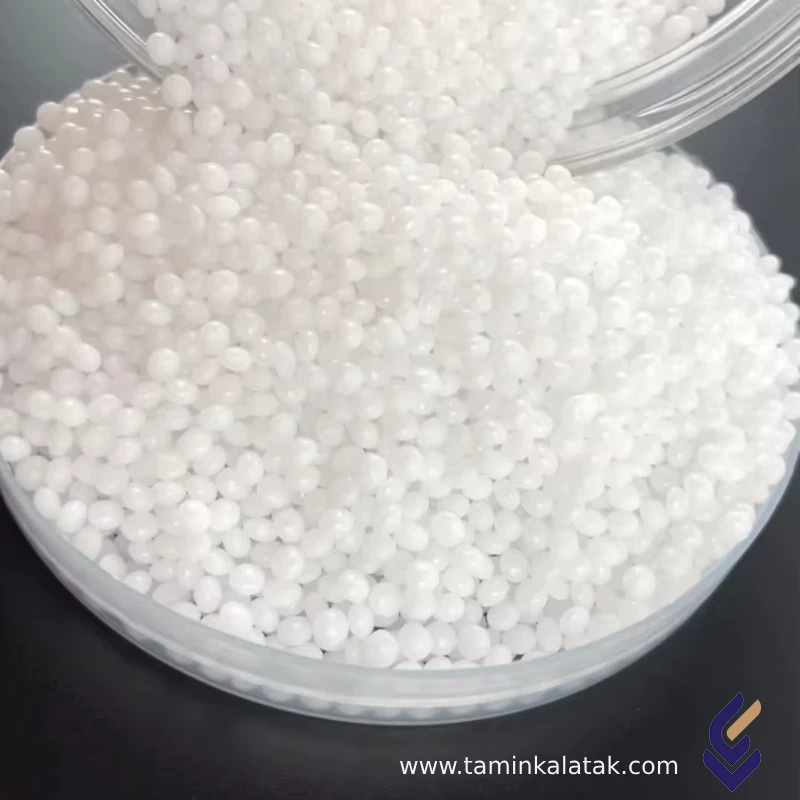

PolyOxyMethylene plastic (POM / Acetal)

Polyoxymethylene (POM), also known as Acetal, Delrin® (a brand name by DuPont), or polyacetal, is a high-performance engineering thermoplastic. It is widely used for its high strength, low friction, and excellent dimensional stability.

Structure

Polyoxymethylene (POM), also known as Acetal, is a semi-crystalline thermoplastic composed of repeating oxymethylene (-CH₂O-) units in its molecular structure. It exists in two main forms: homopolymer (POM-H) and copolymer (POM-C). The homopolymer version, such as DuPont’s Delrin®, has a highly regular and crystalline structure, providing higher mechanical strength and stiffness. The copolymer variant incorporates comonomers to reduce the risk of thermal and oxidative degradation, improving chemical resistance and thermal stability. The strong carbon-oxygen bonds in POM’s backbone contribute to its high strength, low friction, and excellent wear resistance, making it an ideal material for precision components in various industries. However, due to its highly crystalline nature, POM can be brittle under certain conditions and has limited adhesion properties, often requiring surface treatments for bonding or painting.

Properties

Polyoxymethylene (POM), or Acetal, is a high-performance engineering thermoplastic known for its excellent mechanical strength, stiffness, and dimensional stability. It has a low coefficient of friction and high wear resistance, making it ideal for applications involving sliding or moving parts. POM exhibits good chemical resistance, particularly against solvents, fuels, and weak acids, while also having low moisture absorption, allowing it to maintain its properties in humid environments. It offers good electrical insulating properties, making it suitable for electronic components. Additionally, POM has a high degree of crystallinity, contributing to its rigidity and durability. However, it has poor resistance to ultraviolet radiation, can degrade at high temperatures, and has limited adhesion properties, requiring special treatments for bonding and painting.

Advantages

- High mechanical strength and rigidity

- Excellent wear and abrasion resistance

- Low friction, making it ideal for moving parts

- Good dimensional stability with low moisture absorption

- Strong chemical resistance to solvents, fuels, and weak acids

- Good electrical insulating properties

- Easy to machine and fabricate into precise components

Disadvantages

- Poor resistance to UV radiation, leading to degradation over time

- Limited heat resistance, typically usable below 120°C

- Can be brittle under high-impact loads

- Difficult to bond or paint without special surface treatments

- Susceptible to thermal degradation if overheated during processing

Applications

- Automotive – Fuel system components, gears, door locks, seatbelt parts

- Industrial machinery – Bearings, bushings, conveyor belt parts, rollers

- Consumer products – Zippers, buckles, eyeglass frames, knife handles

- Electronics – Switches, connectors, electrical housings

- Medical devices – Insulin pens, inhaler components, surgical instruments

- Aerospace – Lightweight gears, fasteners, interior components

Applications

| Applications | , , , , |

|---|

PolyOxyMethylene plastic

| Products | Grade | MFI | Density(g/cm³) | Applications | Process method | Data Sheet | MSDS |

|---|---|---|---|---|---|---|---|

| POM Acetal | Delrin® 150 | 9-12 g/10min | 141,00 | Gears, fuel system components, seatbelt mechanisms Bearings, bushings, rollers, conveyor belt parts Zippers, buckles, knife handles, eyeglass frames Switches, connectors, precision housings Surgical instruments, inhaler components | Injection Molding Extrusion CNC Machining | ||

| POM Acetal | Celcon® M90 | 8 cm³/min | 141,00 | Parts requiring high stiffness and low friction Precision parts such as gears and bearings Components like small gear wheels, ski bindings, fasteners, and lock systems | Injection Molding Extrusion Blow Molding Film Extrusion |