Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Plasticizers are chemical additives added to polymers to increase their flexibility, ductility, and processability.

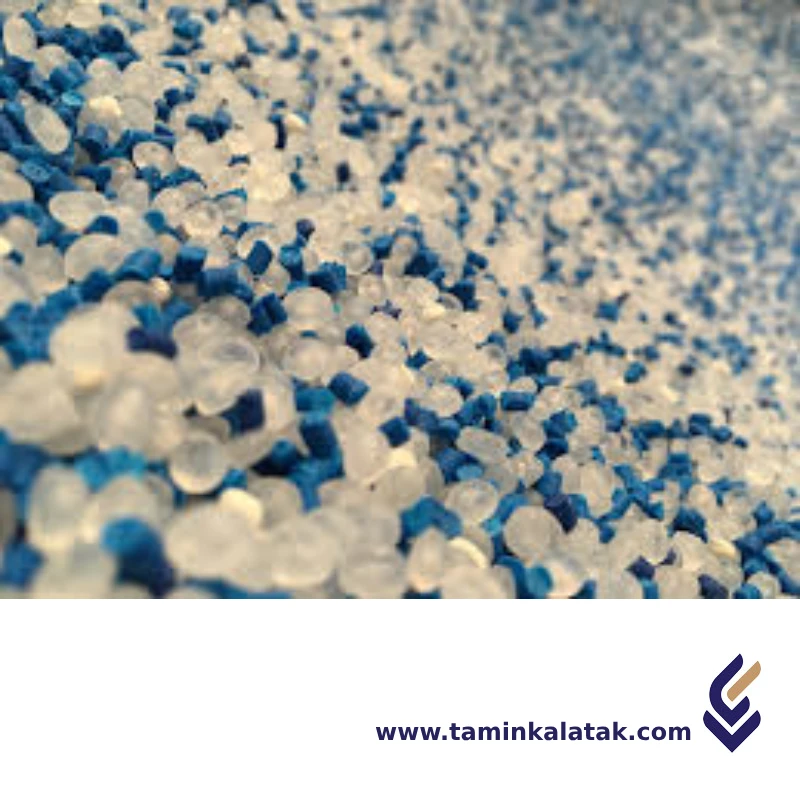

PolyOlefin Elastomer (POE)

Polyolefin Elastomer (POE) is a type of thermoplastic elastomer that combines the properties of both rubber and plastic. It is produced from the copolymerization of olefins, typically ethylene with either alpha-olefins or other monomers like propylene. The material is flexible, durable, and resistant to environmental factors, making it ideal for various applications.

Structure

Polyolefin Elastomer (POE) is a copolymer made from the polymerization of olefins, typically ethylene, combined with other monomers like alpha-olefins (such as 1-butene, 1-hexene, or 1-octene). The structure of POE consists of a flexible, amorphous polymer chain with a low degree of crystallinity. The polymerization process results in a random distribution of the monomers along the polymer chain, which gives the material its elastomeric properties, allowing it to stretch and return to its original shape. The ethylene segments form the backbone of the polymer, while the incorporation of alpha-olefins introduces branches into the polymer chain, enhancing the material’s flexibility and reducing crystallinity. This structure enables POE to have characteristics similar to rubber while maintaining the ease of processing typical of thermoplastics. The balance of crystalline and amorphous regions provides the polymer with its desirable mechanical properties, such as low density, good elasticity, and resistance to environmental factors.

Properties

Polyolefin Elastomer (POE) is known for its combination of rubber-like flexibility and the ease of processing typical of thermoplastics. It exhibits excellent elasticity, allowing it to stretch and recover its original shape, making it ideal for applications requiring flexibility. POE has low density, which contributes to its light weight and efficient material usage. The material is highly resistant to environmental factors such as moisture, UV radiation, and a range of chemicals, making it durable and long-lasting in outdoor and industrial settings. It also has good thermal stability and can maintain its properties over a wide temperature range, though its performance is best in moderate temperatures. POE has low viscosity, which enhances its processability, allowing for easier manufacturing using methods like injection molding, extrusion, and blow molding. It is also compatible with various fillers and additives, which can be used to tailor its properties for specific applications. Overall, POE is valued for its balance of durability, flexibility, and processability, making it suitable for a wide range of applications in industries like automotive, consumer goods, and packaging.

Applications of Polyolefin Elastomer (POE)

- Automotive: Used for seals, gaskets, weatherstripping, and interior components due to its flexibility and resistance to environmental factors.

- Consumer Goods: Found in products like footwear, toys, soft-touch materials, and molded products that require a combination of flexibility and durability.

- Industrial: Used in hoses, tubing, gaskets, and non-slip coatings for machinery due to its resistance to wear and chemicals.

- Packaging: Employed in stretch films, protective coatings, and flexible packaging materials, providing excellent durability and stretchability.

- Medical: Utilized in flexible medical components, such as tubing and device seals, due to its biocompatibility and processability.

- Electrical: Used for wire coatings and insulation due to its electrical insulating properties.

Advantages of Polyolefin Elastomer (POE)

- High Flexibility: Offers rubber-like flexibility while being easy to process as a thermoplastic.

- Lightweight: Low density makes it suitable for lightweight applications.

- Durability: Excellent resistance to moisture, UV radiation, and chemicals, contributing to a longer lifespan in outdoor and industrial environments.

- Ease of Processing: Can be easily molded using standard thermoplastic techniques, such as extrusion and injection molding.

- Versatile: Can be modified with additives and fillers to suit a variety of applications, providing customization of properties like hardness, flexibility, and processability.

- Low Viscosity: Its low viscosity allows for better flow during processing, making it more efficient to work with.

Disadvantages of Polyolefin Elastomer (POE)

- Cost: It can be more expensive than some other materials, such as conventional polyethylenes or rubbers, particularly in high-performance applications.

- Heat Resistance: While POE offers good thermal stability, it may not perform as well as other materials at higher temperatures (e.g., above 150°C).

- Plasticizer Migration: In some formulations, plasticizers can migrate out of the material over time, potentially affecting the physical properties or appearance.

- Limited High-Temperature Performance: POE does not have the same high-temperature performance as other elastomers like silicones or thermoplastic vulcanizates (TPVs).

- Environmental Impact: Though POE is relatively environmentally friendly compared to other synthetic materials, its production and disposal still contribute to environmental concerns related to plastics.

Applications

| Applications | , , , , , |

|---|

PolyOlefin Elastomer (POE)

| Products | Grade | MFI(g/10 min) | Density (g/Cm³) | Applications | Process method | Data Sheet | MSDS |

|---|---|---|---|---|---|---|---|

| Polyolefin Elastomer | Engage™ | 1-30 | 0.85-0.91 | seals, gaskets, weatherstripping, flexible packaging, protective coatings, footwear, sports equipment, toys, tubing and seals | Injection Molding Extrusion Blow Molding Thermoforming | ||

| Polyolefin Elastomer | Exact® | 1-30 | 0.87-0.91 | seals, gaskets, weatherstripping footwear, toys, packaging films, stretch films, wire coatings | Injection Molding Extrusion Blow Molding Thermoforming Compression Molding |