Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Engineering polymers are high-performance plastics that exhibit superior mechanical, thermal, chemical, and electrical properties compared to standard commodity plastics.

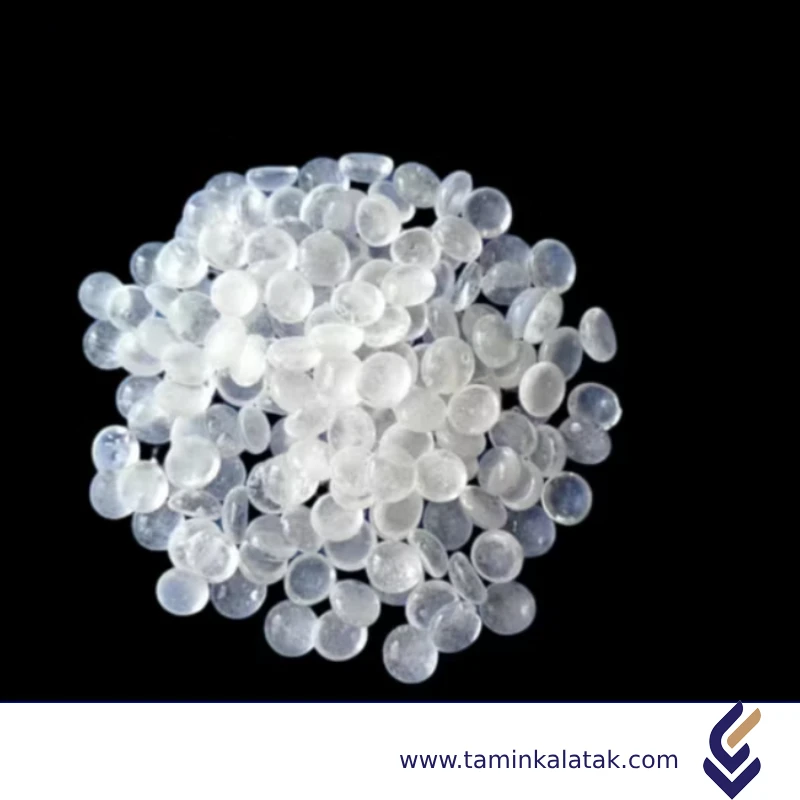

PolyKetone (PK)

PolyKetone (PK) is a high-performance thermoplastic polymer known for its excellent mechanical properties, chemical resistance, and environmental sustainability. It is primarily composed of carbon monoxide (CO) and olefins (such as ethylene and propylene) through a catalytic polymerization process. The unique molecular structure of PK provides a balanced combination of toughness, wear resistance, and low moisture absorption, making it suitable for various industrial applications.

Structure

PolyKetone (PK) is a linear alternating copolymer composed of carbon monoxide (CO) and olefins such as ethylene and propylene. Its structure consists of repeating ketone (C=O) functional groups positioned between hydrocarbon units, forming a highly regular and crystalline polymer chain. This alternating arrangement of carbonyl and alkyl groups contributes to its unique mechanical strength, chemical resistance, and thermal stability. The presence of ketone groups enhances intermolecular interactions, providing superior wear resistance and low moisture absorption compared to other engineering plastics. The highly ordered molecular structure also results in excellent toughness and impact resistance, making PolyKetone a versatile material for demanding applications.

Properties

PolyKetone (PK) exhibits a unique combination of mechanical, thermal, and chemical properties that make it a high-performance engineering plastic. It has exceptional strength, toughness, and impact resistance, surpassing many conventional polymers such as nylon and polyoxymethylene (POM). Its high wear resistance and low friction make it ideal for applications involving moving parts and high-load conditions. PolyKetone also demonstrates excellent chemical resistance, remaining stable in the presence of acids, bases, fuels, and solvents, which enhances its durability in harsh environments. Additionally, it has low moisture absorption, ensuring dimensional stability even in humid conditions. The material offers high thermal stability, maintaining its properties over a wide temperature range, and it possesses good electrical insulating properties, making it suitable for electronic components. Furthermore, PolyKetone is environmentally friendly, as it is synthesized from carbon monoxide and olefins, reducing reliance on petroleum-based resources while offering recyclability and sustainability advantages.

Advantages of PolyKetone (PK)

- High strength, toughness, and impact resistance

- Excellent wear resistance and low friction properties

- Superior chemical resistance to acids, bases, fuels, and solvents

- Low moisture absorption, ensuring dimensional stability

- High thermal stability across a wide temperature range

- Good electrical insulating properties for electronic applications

- Environmentally friendly, derived from carbon monoxide and olefins

- Recyclable and sustainable compared to petroleum-based polymers

Disadvantages of PolyKetone (PK)

- Higher cost compared to conventional plastics like nylon and POM

- Limited availability due to fewer manufacturers producing PK

- Processing challenges requiring specific conditions for molding and extrusion

- Lower heat resistance compared to some high-performance polymers like PEEK

Applications of PolyKetone (PK)

- Automotive: Fuel system components, gears, connectors, and under-the-hood parts

- Industrial Machinery: Bearings, seals, conveyor belts, and gears

- Electronics: Electrical connectors, insulators, and circuit components

- Consumer Goods: Sports equipment, power tools, and kitchen utensils

- Medical Devices: Drug delivery components and durable medical tools

- Oil & Gas Industry: Seals and gaskets resistant to harsh chemicals and fuels

Applications

| Applications | , , , , |

|---|

PolyKetone (PK)

| Products | Density (g/Cm³) | Applications | Process method | Data Sheet | MSDS |

|---|---|---|---|---|---|

| PolyKetone (PK) | 122,00 | Automotive fuel system components Gears and bearings Electrical connectors and insulation Pipes and fittings Medical and pharmaceutical equipment Packaging films and containers Textile fibers Sports equipment Consumer electronics | Injection Molding Extrusion Blow Molding Rotational Molding |