Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Engineering polymers are high-performance plastics that exhibit superior mechanical, thermal, chemical, and electrical properties compared to standard commodity plastics.

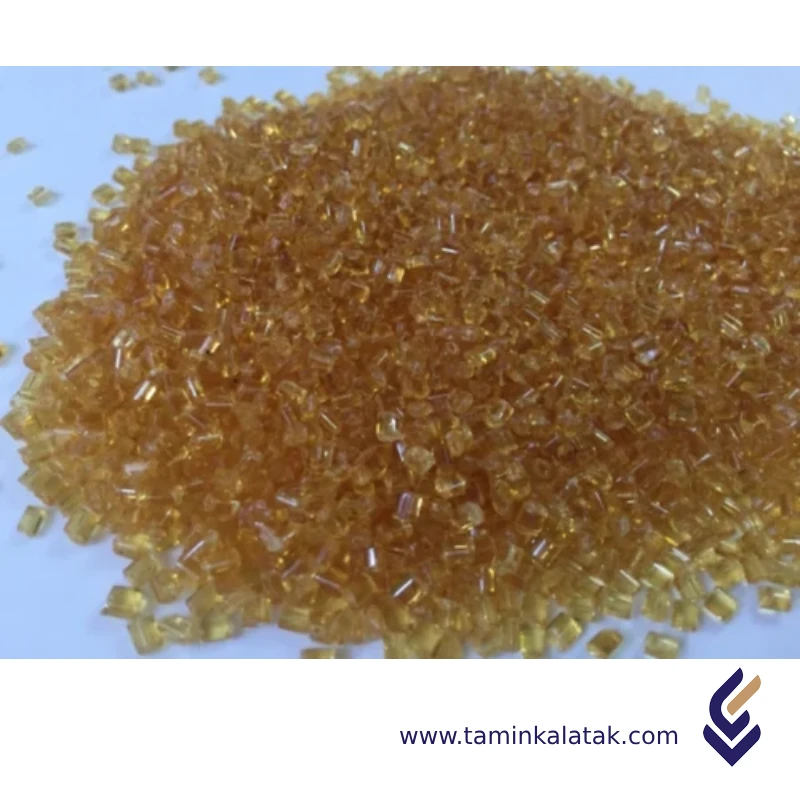

PolyEtherImide (PEI)

Polyetherimide (PEI) is a high-performance engineering thermoplastic known for its excellent mechanical, thermal, and chemical properties. It is commonly used in demanding applications across industries like aerospace, automotive, medical, and electronics.

Structure

Polyetherimide (PEI) is an amorphous thermoplastic polymer with a backbone structure that consists of repeating ether and imide groups. The ether (-O-) linkages provide flexibility and improved processability, while the imide (-CO-N-CO-) groups contribute to the polymer’s high thermal stability, mechanical strength, and chemical resistance. The structure typically includes aromatic rings, which enhance rigidity and thermal performance. The combination of these functional groups results in a polymer that exhibits excellent dimensional stability, flame resistance, and dielectric properties. Due to this unique molecular structure, PEI maintains its strength and stiffness at high temperatures, making it suitable for demanding engineering applications.

Properties

Polyetherimide (PEI) is a high-performance thermoplastic known for its exceptional mechanical, thermal, and electrical properties. It has a high glass transition temperature of around 217°C, allowing it to maintain structural integrity in extreme heat conditions. PEI exhibits excellent tensile and flexural strength, providing durability and resistance to deformation under load. It is naturally flame-retardant with low smoke emission, making it ideal for aerospace and electronic applications. The polymer also offers good chemical resistance to a variety of solvents, oils, and weak acids, though it is sensitive to strong bases. With excellent electrical insulation properties, PEI is widely used in electrical and electronic components. Additionally, it has low thermal expansion and good dimensional stability, ensuring precision in high-temperature environments. Its inherent transparency and ability to be colored make it versatile for different industrial applications.

Applications of Polyetherimide (PEI)

- Aerospace components such as interior panels, ducts, and electrical connectors due to flame resistance and lightweight properties.

- Automotive parts including under-the-hood components, sensor housings, and lighting systems requiring high heat resistance.

- Medical devices and surgical instruments that require repeated sterilization and durability.

- Electrical and electronic components such as insulating connectors, circuit boards, and semiconductor processing equipment.

- 3D printing, particularly in high-performance applications using PEI-based filaments like ULTEM™ 9085 and ULTEM™ 1010.

- Industrial and food processing equipment where high heat and chemical resistance are necessary.

Advantages of Polyetherimide (PEI)

- High thermal stability, maintaining performance in temperatures up to 217°C.

- Excellent mechanical strength and stiffness, providing durability in demanding environments.

- Naturally flame-retardant with low smoke emission, ideal for safety-critical applications.

- Good chemical resistance against many solvents, oils, and weak acids.

- Excellent electrical insulation properties, making it suitable for electronic applications.

- Good dimensional stability with low creep, ensuring precision over time.

- Can be processed using various methods including injection molding, extrusion, and 3D printing.

Disadvantages of Polyetherimide (PEI)

- Relatively high cost compared to other engineering plastics.

- Brittle nature under certain conditions, especially in impact-prone applications.

- Limited resistance to strong bases and some polar solvents.

- Requires high processing temperatures, which may increase manufacturing costs.

- Can absorb moisture, affecting mechanical properties if not properly dried before processing.

Applications

| Applications | , , , , |

|---|

PEI

| Products | Grade | MFI(g/10 min) | Density (g/Cm3) | Applications | Process method | Data Sheet | MSDS |

|---|---|---|---|---|---|---|---|

| PolyEtherImide (PEI) | ULTEM™ 1000 | 6-9 | 127,00 | sensor housings, under-the-hood components, connectors | Injection Molding Extrusion Thermoforming CNC Machining | ||

| PolyEtherImide (PEI) | ULTEM™ 1010 | 3-6 | 127,00 | Sterilizable surgical instruments, medical trays, and autoclave-compatible parts FDA and NSF-compliant applications like food molds and processing equipment High-performance under-the-hood components, electrical connectors, and sensor housings | Injection Molding Extrusion 3D Printing Thermoforming CNC Machining |