Polyether allyl alcohol

Polyether Alkyl Alcohols are a class of non-ionic surfactants produced through the ethoxylation of fatty alcohols.

These compounds contain both hydrophilic polyether chains (usually polyethylene glycol) and hydrophobic alkyl chains, giving them excellent ability to reduce surface tension, enhance wetting, and improve dispersibility.

They are widely used in detergent, agricultural, coating, adhesive, and industrial formulation applications.

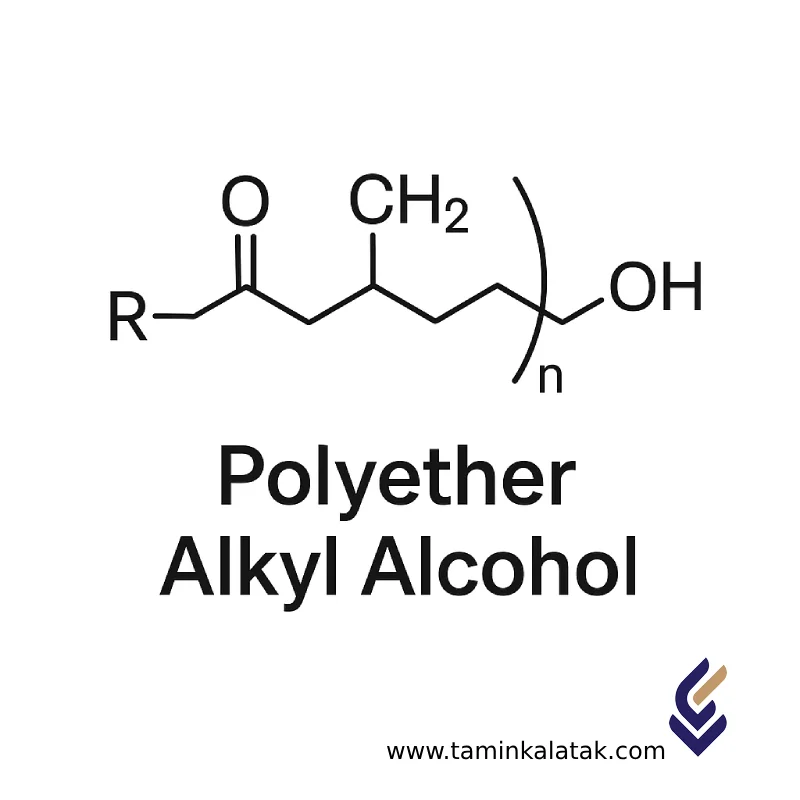

Chemical Structure of Polyether Alkyl Alcohol

General Formula: R–(OCH₂CH₂)ₙ–OH

-

R group: Alkyl chain (typically C₈–C₁₆)

-

n: Number of ethylene oxide units (usually between 3 and 15)

-

Chemical nature: Non-ionic ethoxylated surfactant with amphiphilic properties (hydrophilic–hydrophobic balance)

Physical and Chemical Properties

| Property | Description |

|---|---|

| Appearance | Clear to semi-viscous or wax-like liquid, colorless to pale yellow |

| Odor | Mild alcoholic odor or odorless |

| Cloud Point | Depends on ethoxylation degree (n value) |

| Solubility | Soluble in water and most polar organic solvents |

| Stability | Stable under neutral and mildly alkaline pH conditions |

Applications of Polyether Alkyl Alcohol

1. Detergent and Cleaning Industries

-

Effective non-ionic surfactant with strong degreasing capability.

-

Suitable for household and industrial cleaning formulations (surface cleaners, glass cleaners, multipurpose cleaners).

-

Compatible with anionic and enzyme-based systems.

2. Agricultural Formulations

-

Acts as a spreader–wetting agent in pesticide and liquid fertilizer formulations.

-

Enhances leaf absorption and reduces wash-off of spray solutions.

-

Decreases surface tension of droplets for better coverage.

3. Paints and Coatings

-

Improves wetting in water-based paints.

-

Reduces surface tension and enhances film uniformity.

-

Serves as an eco-friendly alternative to petroleum-based surfactants.

4. Adhesives and Resins

-

Enhances component compatibility in waterborne systems.

-

Aids in emulsification of polymer formulations.

-

Increases surface lubricity and flow properties.

5. Cosmetics and Personal Care (limited use)

-

Functions as a dispersing, moisturizing, or homogenizing agent in select hair and skin formulations.

-

Must comply with IFRA safety guidelines and undergo dermal irritation testing before use.

Industrial Application Areas

-

Household and industrial detergents

-

Agricultural chemicals and adjuvants

-

Water-based paints and coatings

-

Emulsion-based adhesives and resins

-

Cosmetic formulations (restricted and regulated use)

Advantages of Polyether Alkyl Alcohol

-

High compatibility with aqueous and polar systems

-

Excellent surface tension reduction capability

-

Biodegradable in many natural-grade formulations

-

Stable across a wide pH range

-

Adjustable performance through variation in alkyl chain length and ethoxylation degree

Limitations of Polyether Alkyl Alcohol

-

High viscosity in certain grades

-

Sensitive to extremely acidic or basic environments over long exposure

-

Some grades may irritate skin or eyes upon direct contact

-

Restricted cosmetic use without full toxicological safety validation

Safety and Handling of Polyether Allyl Alcohol

Substance name: Polyether Allyl Alcohol

Chemical group: Reactive polyether polyols with allyl functionality

Typical uses: Raw material for UV-curable resins, copolymers, pressure-sensitive adhesives, and coatings

Physical and Chemical Hazards

| Hazard Type | Description |

|---|---|

| Flammability | Depending on molecular weight and composition, some grades have a low flash point (90–130 °C). |

| Skin and Eye Irritation | Liquid may cause moderate irritation upon direct contact. |

| Respiratory Sensitivity | Vapors released during heating or spraying may irritate the respiratory tract. |

| Thermal and Photochemical Stability | May slowly polymerize or degrade under prolonged UV exposure or excessive heat. |

Personal Protective Measures

| Protective Equipment | Recommendation |

|---|---|

| Gloves | Chemical-resistant gloves (nitrile or butyl rubber) are mandatory. |

| Eye & Face Protection | Use safety goggles or a full-face shield to prevent splashes. |

| Protective Clothing | Wear chemical-resistant lab coats or long-sleeved industrial garments. |

| Respiratory Protection | For large-scale or spray applications, use a half-face respirator with organic vapor filter. |

Emergency Measures

In case of spill:

-

Absorb the liquid with non-combustible absorbents (e.g., diatomaceous earth or industrial absorbent powder).

-

Ensure adequate ventilation and keep away from heat or open flame.

In case of skin or eye contact:

-

Immediately rinse with plenty of water and mild soap for at least 15 minutes.

-

Seek medical attention if irritation persists.

In case of inhalation:

-

Move the exposed person to fresh air.

-

If symptoms of respiratory distress occur, seek immediate medical attention.

Storage Conditions

| Parameter | Recommendation |

|---|---|

| Optimal storage temperature | 5–30 °C — avoid freezing or overheating. |

| Container type | Steel or polyethylene containers with tight seals and protection from moisture. |

| Light stability | Store in dark containers or away from direct sunlight. |

| Incompatible materials | Strong oxidizing agents, mineral acids, and peroxides. |

Final Safety Recommendations

-

Prevent unintended self-polymerization when exposed to UV light or continuous heat.

-

Personnel handling this material must receive training in reactive and UV-sensitive chemical handling.

-

During transport, ensure proper labeling and classification in accordance with UN GHS standards.

-

Maintain an updated SDS (Safety Data Sheet) containing detailed information on toxicity, ecotoxicity, and reactivity at the workplace.

Polyether allyl alcohol

| Products | Chemical formula | CAS number | Grade | Solubility in water | Vapor pressure | Melting point | Density (at 20°C) | Physical appearance |

|---|---|---|---|---|---|---|---|---|

| C10–C12 Alkyl Poly(ethylene glycol) Ether (with 7 moles of ethylene oxide) | R–(OCH₂CH₂)_n–OH، با R = C₁₀–C₁₂ و n ≈ 7 | 68439-46-3 (generic number for polyethoxylated alkyl compounds) | Industrial Grade, with special grades for detergent, agricultural or sanitary | Completely soluble in water, especially at higher temperatures | Very low, typically < 0.01 hPa at 20 °C | Usually below 0°C, often liquid at ambient temperature | About 0.98 – 1.02 g/cm³ (varies with chain and EO degree) | Clear to pale yellow or semi-viscous liquid (depending on chain and n) |