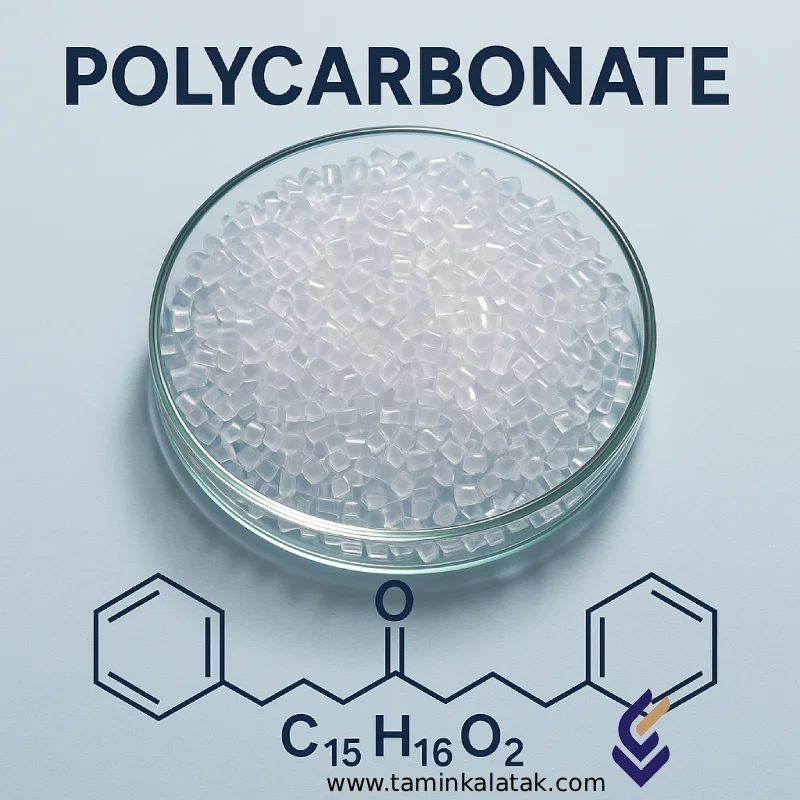

polycarbonate

Polycarbonate (PC) is a high-performance transparent engineering thermoplastic primarily produced through the polymerization of bisphenol A (BPA) and phosgene (COCl₂).

Renowned for its exceptional impact resistance, optical clarity (up to 90% light transmission), thermal stability, and excellent processability, polycarbonate is widely used across industries such as safety equipment, automotive components, bullet-resistant glazing, medical devices, and electronics.

Its light weight and durability make PC an ideal substitute for glass and certain metals in demanding applications.

Chemical and Structural Overview

Polycarbonate consists of repeating carbonate linkages (–O–(C=O)–O–) within its polymer backbone.

It is typically synthesized via the reaction of bisphenol A (BPA) with phosgene or diphenyl carbonate (DPC).

This molecular configuration provides a unique balance between transparency, mechanical strength, thermal resistance, and ease of molding, establishing PC as one of the most versatile engineering polymers available.

Key Physical and Chemical Properties

-

Optical Transparency: Up to ~90% light transmittance, comparable to glass

-

Density: ~1.20–1.22 g/cm³ (lighter than glass)

-

Impact Strength: Up to 200× stronger than glass of equivalent thickness

-

Heat Resistance: Maintains mechanical integrity up to 120–130 °C

-

Chemical Resistance: Resistant to oils and greases; sensitive to strong organic solvents (e.g., acetone, toluene)

-

Processing Methods: Suitable for injection molding, extrusion, blow molding, and thermoforming

Major Applications

-

Automotive Industry: Headlamp lenses, impact-resistant glazing, interior panels

-

Construction: Polycarbonate sheets for skylights, greenhouses, and roofing panels

-

Electronics: CD/DVD discs, equipment housings, LED covers, and electrical insulators

-

Medical Field: Durable and sterilizable laboratory ware, device components

-

Personal Protection: Helmets, face shields, and safety goggles

-

Specialty Packaging: Reusable bottles and high-impact containers

Advantages

-

Excellent optical clarity with high transparency

-

Superior impact and mechanical strength

-

Lightweight alternative to glass and metal

-

Outstanding dimensional stability and heat resistance

-

Self-extinguishing behavior; can be formulated with flame retardants

-

Long-term durability in harsh environmental conditions

Limitations

-

Scratch-sensitive surface — often requires hard coating for optical applications

-

UV degradation — may yellow or become brittle under sunlight without stabilizers

-

Higher cost compared to commodity plastics (PE, PP)

-

Moderate resistance to aggressive solvents such as ketones and aromatics

Safety and Storage Guidelines

-

Store in a cool, dry, well-ventilated area, away from direct sunlight

-

Avoid exposure to strong solvents (acetone, toluene, benzene)

-

Use industrial ventilation and protective masks during thermal processing (injection/extrusion)

-

Keep materials sealed to prevent moisture absorption prior to molding

-

Ensure workplace ventilation to avoid buildup of fumes from additives during processing

Summary

Polycarbonate (PC) offers a unique combination of transparency, strength, and versatility, making it a preferred choice in industries that demand both performance and aesthetics.

Its adaptability, toughness, and design flexibility have established it as one of the most valuable engineering plastics in the modern industrial landscape.

Applications

| Applications | , , , , |

|---|

polycarbonate

| Products | Chemical formula | Solubility in water | CAS number | Grade | Vapor pressure | Physical appearance | Density (at 20°C) | Melting point |

|---|---|---|---|---|---|---|---|---|

| Polycarbonate | (C₁₆H₁₄O₃)ₙ | Insoluble in water | 25037-45-0 | (Medical Grade)، Optical Grade | Negligible (at ambient temperature of almost zero) | Transparent, colorless to slightly milky solid | About 1.20 – 1.22 g/cm³ | About 147°C (glass transition point) |