Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A compound is a polymer blend mixed with additives, fillers, and reinforcements to achieve specific properties for end-use applications. A masterbatch is a concentrated mixture of additives or pigments in a carrier resin, used to enhance plastics without altering their base properties.

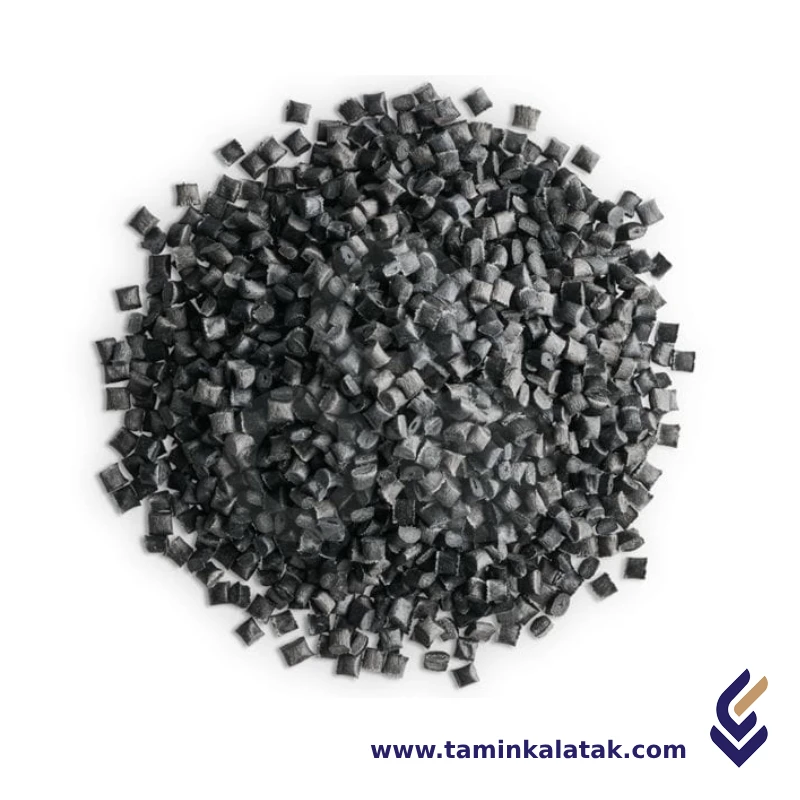

Polyamide Fiber Compounds

Polyamide fiber compounds, commonly known as nylon-based materials, are high-performance engineering polymers widely used for their excellent mechanical strength, durability, and chemical resistance. These fiber compounds are primarily based on PA6 (Nylon 6) and PA66 (Nylon 6,6), with variations including PA11, PA12, PA46, PA6T, and others for specialized applications. They can be modified with additives to enhance properties such as flame retardancy, UV resistance, and thermal stability.

Structure Polyamide fiber compounds

Polyamide fiber compounds are composed of long-chain synthetic polymers formed through the polymerization of diamines and dicarboxylic acids or lactams. The repeating amide (-CONH-) linkage in their molecular structure provides strength, flexibility, and thermal stability. The backbone of polyamide fibers consists of hydrogen bonds between adjacent polymer chains, contributing to their high tensile strength and resistance to wear. The structure can be modified by incorporating reinforcements such as glass fibers, flame-retardant additives, or UV stabilizers to enhance specific properties. Depending on the type, polyamide compounds may exhibit varying degrees of crystallinity, influencing their mechanical performance, moisture absorption, and processability. The arrangement of molecular chains affects characteristics such as melting point, durability, and elasticity, making polyamide fiber compounds suitable for demanding applications in textiles, automotive components, and industrial materials.

Properties Polyamide fiber compounds

Polyamide fiber compounds possess a combination of high mechanical strength, flexibility, and durability, making them suitable for various demanding applications. They exhibit excellent tensile strength and abrasion resistance, allowing them to withstand mechanical stress and wear over time. Their thermal stability enables them to perform well under elevated temperatures, with some grades maintaining integrity above 200°C. These compounds also offer good chemical resistance to oils, solvents, and fuels, making them ideal for automotive and industrial applications. However, polyamides tend to absorb moisture, which can affect dimensional stability and mechanical properties. The addition of reinforcements such as glass fibers or flame-retardant additives can enhance stiffness, fire resistance, and environmental stability. Polyamide fiber compounds also have good impact resistance and elasticity, making them well-suited for textiles, electrical components, and high-performance engineering applications.

Applications Polyamide fiber compounds

- Textiles: Used in clothing, carpets, upholstery, and industrial fabrics due to their durability and flexibility.

- Automotive: Applied in fuel lines, air intake manifolds, connectors, and under-the-hood components for heat and chemical resistance.

- Electronics & Electricals: Used in wire insulation, circuit breakers, switch housings, and connectors due to their electrical insulating properties.

- Industrial Uses: Found in conveyor belts, ropes, filtration systems, and high-performance engineering parts.

- Sports & Outdoor Equipment: Utilized in climbing ropes, fishing lines, and sportswear for strength and resilience.

Advantages Polyamide fiber compounds

- High mechanical strength and wear resistance, ensuring long-lasting performance.

- Excellent thermal stability, withstanding high temperatures in industrial and automotive applications.

- Good chemical resistance against oils, fuels, and solvents.

- Lightweight compared to metals, making it suitable for weight-sensitive applications.

- Flexible and elastic, allowing for diverse applications in textiles and engineering.

- Can be modified with additives for flame retardancy, UV resistance, and enhanced performance.

Disadvantages Polyamide fiber compounds

- High moisture absorption, which can affect dimensional stability and mechanical properties.

- Processing challenges due to high melting points and specific drying requirements.

- Susceptibility to degradation under prolonged UV exposure without stabilizers.

- Can be more expensive than other synthetic fibers, especially high-performance grades.

Applications

| Applications | , , , , , |

|---|

Polyamide Fiber Compounds

| Products | MFI (g/10 min) | Density (g/Cm³) | Applications | Process method | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| Clarifying masterbatch | 5-30 | 0.90-1.10 | Transparent containers, trays, and beverage cups Syringes, IV tubes, and vials requiring high clarity Clear storage boxes, organizers, and kitchenware Light housings, dashboards, and transparent plastic parts Cosmetic packaging, electronic casings, and premium packaging Transparent bottles, sheets, and films | Injection Molding Blow Molding Extrusion and Thermoforming Compounding |