Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

PolyHydroxyButyrate (PHB)

Polyhydroxybutyrate (PHB) is a member of the polyhydroxyalkanoate (PHA) family, recognized as a sustainable alternative to conventional plastics due to its complete biodegradability and environmental compatibility. This biopolymer is produced by microorganisms and is used across various industries, from packaging to medicine.

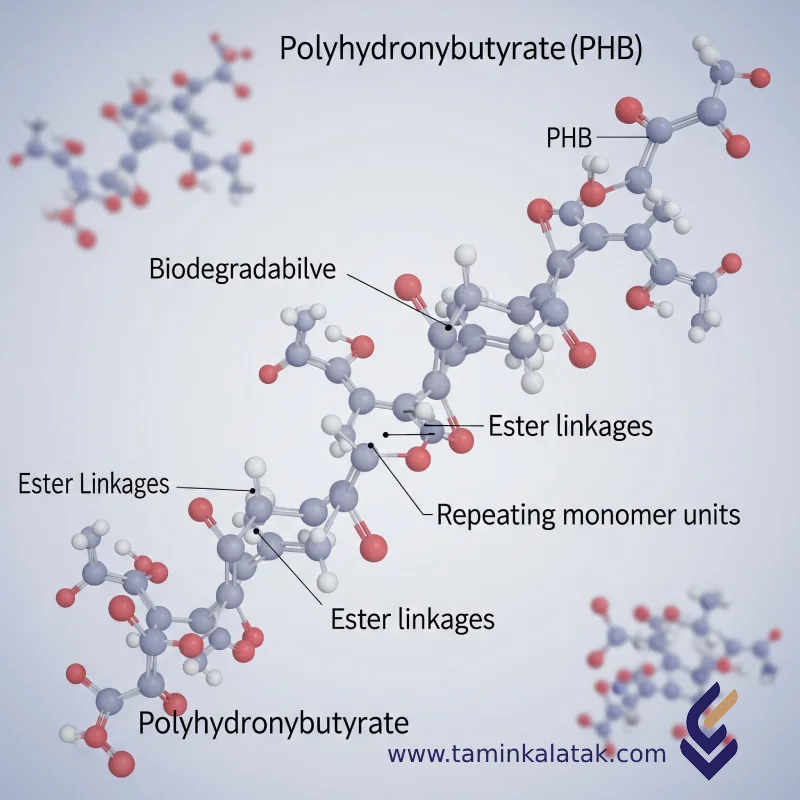

Structure of Polyhydroxybutyrate (PHB)

PHB is a biodegradable polyester with the chemical formula (C₄H₆O₂)ₙ. It is synthesized by certain microorganisms under specific nutrient-limited conditions (such as nitrogen deficiency). The high crystallinity of PHB (up to 60–70%) gives it mechanical strength and rigidity comparable to polypropylene (PP). However, unlike PP, PHB is completely biodegradable. Its polymer chains are generally linear, and its mechanical properties depend on the molecular weight and production conditions.

Properties of Polyhydroxybutyrate (PHB)

-

Biodegradability: Completely decomposed by microorganisms in natural environments such as soil, seawater, and compost.

-

Biocompatibility: Non-toxic and suitable for medical applications.

-

Mechanical strength: Hardness and tensile strength comparable to conventional plastics like polypropylene.

-

Thermal resistance: Melting point between 160–180°C.

-

Renewable origin: Produced from biological sources such as glucose, agricultural waste, or vegetable oils.

Applications of Polyhydroxybutyrate (PHB)

-

Packaging: Production of thin films, biodegradable bags, and disposable containers.

-

Medical field: Used in absorbable sutures, biocompatible implants, and drug delivery systems.

-

Agriculture: Biodegradable mulching films and plant pots.

-

Textile industry: Production of fibers for sustainable fabrics.

-

Industrial products: Molded parts for general-purpose applications.

Disadvantages of Polyhydroxybutyrate (PHB)

Despite its many advantages, PHB also has some limitations:

-

High production cost: Microbial fermentation and extraction processes are expensive.

-

Brittleness: High crystallinity can lead to fragility in certain applications.

-

Variable degradation rate: In low-oxygen environments, the decomposition process can be slow.

-

Limited processability: Due to its high melting temperature and viscosity, PHB can be challenging to process using some conventional methods.

Advantages of Polyhydroxybutyrate (PHB)

-

Reduced plastic pollution: Fully biodegradable in the environment, reducing dependence on petroleum-based plastics.

-

Versatile applications: Suitable for use in medical, packaging, and agricultural industries.

-

Sustainable production: Can be made from renewable and waste biomass resources.

-

High safety: Non-toxic and safe for food-contact applications.

Applications

| Applications | , , , , , |

|---|

PolyHydroxyButyrate (PHB)

| Products | Applications | Grid | Melt Flow Index (MFI) (g/10 min) | Density (g/cm³) | Process method |

|---|---|---|---|---|---|

| Polyhydroxybutyrate (PHB) | Biodegradable packaging, disposable containers | PHB 100 | 1.5 – 3.5 | 1.25 – 1.27 | Injection molding, extrusion |

| Polyhydroxybutyrate (PHB) | Agricultural films, food packaging | PHB 300 | 5.0 – 8.0 | 1.25 | Filmmaking, blow molding |

| Polyhydroxybutyrate (PHB) | Medical devices, biomedical, implants | PHB-Copolymer | 2.0 – 4.0 | 1.22 – 1.26 | 3D printing, filmmaking |