Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A compound is a polymer blend mixed with additives, fillers, and reinforcements to achieve specific properties for end-use applications. A masterbatch is a concentrated mixture of additives or pigments in a carrier resin, used to enhance plastics without altering their base properties.

Phenol/ Formaldehyde resins (PF)

Phenol-Formaldehyde (PF) resins are synthetic polymers obtained by the reaction of phenol with formaldehyde. They are among the oldest synthetic polymers and are widely used due to their excellent thermal stability, chemical resistance, and mechanical strength.

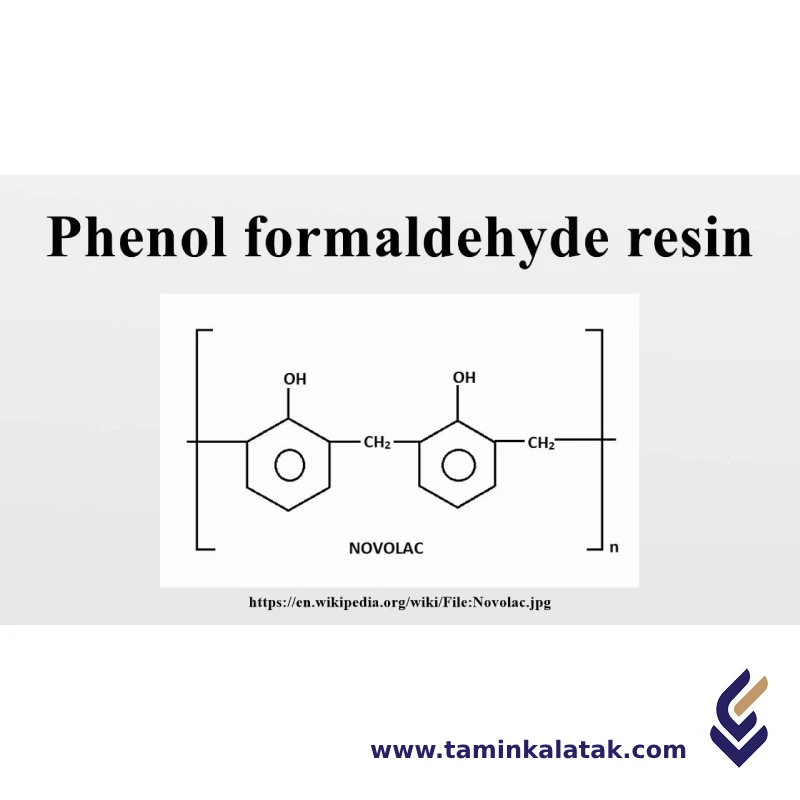

Structure Phenol-Formaldehyde

Phenol-formaldehyde resins are thermosetting polymers formed through the reaction of phenol with formaldehyde under acidic or basic conditions. The structure of these resins varies depending on the synthesis process. In the case of novolac resins, which are produced under acidic conditions with a formaldehyde-to-phenol ratio of less than one, the structure consists of linear chains of phenol units linked by methylene (-CH₂-) bridges. These resins require a curing agent, such as hexamethylenetetramine, to form a three-dimensional cross-linked network. On the other hand, resole resins, synthesized under basic conditions with an excess of formaldehyde, have a partially cross-linked structure due to the presence of hydroxymethyl (-CH₂OH) groups, which can further react upon heating to form a rigid, highly cross-linked network. This cross-linking gives phenol-formaldehyde resins their excellent thermal stability, chemical resistance, and mechanical strength, making them suitable for applications in adhesives, laminates, coatings, and molding compounds.

Properties Phenol-Formaldehyde

Phenol-formaldehyde resins possess several important properties that make them highly useful in industrial applications. They exhibit excellent thermal stability, allowing them to withstand high temperatures without significant degradation. These resins also have high mechanical strength and rigidity, making them suitable for structural applications. Their chemical resistance is another key feature, as they are resistant to acids, bases, and solvents, ensuring durability in harsh environments. Additionally, phenol-formaldehyde resins have good electrical insulation properties, making them ideal for use in electrical and electronic components. They also possess inherent flame resistance, as they are self-extinguishing and do not easily catch fire. However, despite these advantages, they can be brittle and release formaldehyde, which requires controlled handling and proper ventilation during processing.

Applications Phenol-Formaldehyde

- Used as adhesives and binders in plywood, particleboard, and laminates

- Employed in molding compounds for manufacturing electrical switches, knobs, and handles

- Used in coatings and varnishes for wood, metals, and electrical components

- Serves as a binder in abrasive products such as grinding wheels

- Utilized in insulation materials like fiberglass and composite structures

- Applied in foundry sand molds for metal casting

Advantages Phenol-Formaldehyde

- High thermal stability, making it resistant to heat and fire

- Excellent mechanical strength and rigidity for structural applications

- Strong adhesion properties, making it an effective bonding agent

- Good chemical resistance to acids, bases, and solvents

- Provides electrical insulation, suitable for electrical applications

Disadvantages Phenol-Formaldehyde

- Brittle nature, which can lead to cracking under stress

- Potential formaldehyde emissions, requiring controlled processing

- Limited flexibility compared to some other synthetic polymers

- Can be expensive compared to alternative resins in certain applications

Applications

| Applications | , , , , |

|---|

Phenol/ Formaldehyde resins (PF)

| Products | Density (g/mm3) | Applications | Data Sheet | MSDS |

|---|---|---|---|---|

| Phenol formaldehyde resins (PF) | 1.2-1.3 | Adhesives and Binders Molding Compounds Coatings and Varnishes Abrasives Insulation Materials Foundry Industr |