Polyethylene furanoate (PEF) is a bio-based and biodegradable polymer recognized as a potential alternative to polyethylene terephthalate (PET) for packaging and various industrial applications. This polymer is synthesized from the monomers furan-2,5-dicarboxylate and ethylene glycol, offering improved mechanical and thermal properties compared to PET.

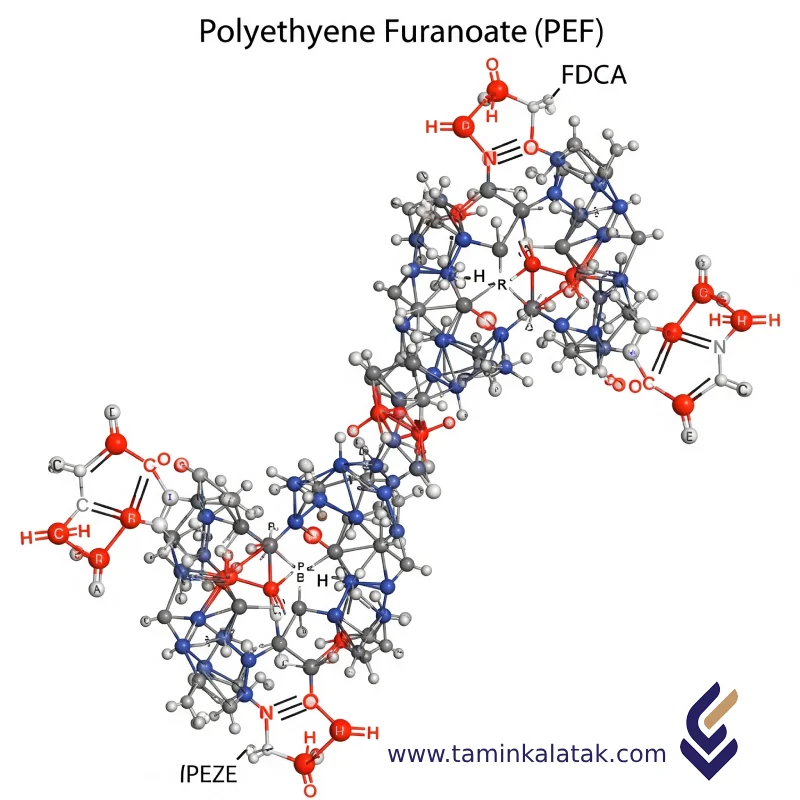

Structure PolyEthylene Furanoate

PEF is produced through a polymerization reaction involving the monomers furan-2,5-dicarboxylic acid (FDCA) and ethylene glycol (EG). The furan ring in its structure enhances the rigidity and thermal resistance of the polymer. The chemical structure of PEF can be described as follows:

-

The main polymer chain consists of ester linkages connected to a furan ring.

-

The furan ring, due to its unique aromatic-like structure, contributes to the polymer’s enhanced mechanical and thermal properties.

Properties PolyEthylene Furanoate

-

Bio-based and renewable: derived from biological resources such as carbohydrates

-

High thermal resistance: melting point around 215–220°C

-

Excellent gas barrier properties: lower permeability to oxygen and carbon dioxide compared to PET

-

Good transparency and mechanical strength: high tensile strength with optical clarity

-

Recyclable: capable of both thermal and chemical recycling

Applications PolyEthylene Furanoate

-

Food and beverage packaging, owing to its superior gas barrier performance

-

Manufacturing of plastic bottles with extended product shelf life

-

Textile and industrial filament production

-

Automotive and electronic components requiring high thermal resistance

Disadvantages PolyEthylene Furanoate

-

Higher production cost compared to polyethylene terephthalate (PET)

-

Requires specialized technology for processing due to its unique properties

-

Still limited in large-scale commercialization compared to PET

Advantages PolyEthylene Furanoate

-

Environmentally friendly due to its biological origin and recyclability

-

Superior mechanical and thermal performance compared to PET

-

Reduced gas permeability, enhancing product preservation and shelf life

-

Decreased dependence on fossil-based raw materials