Polycaprolactone (PCL) is an organic, biodegradable polyester produced through the ring-opening polymerization (ROP) of the monomer ε-caprolactone.

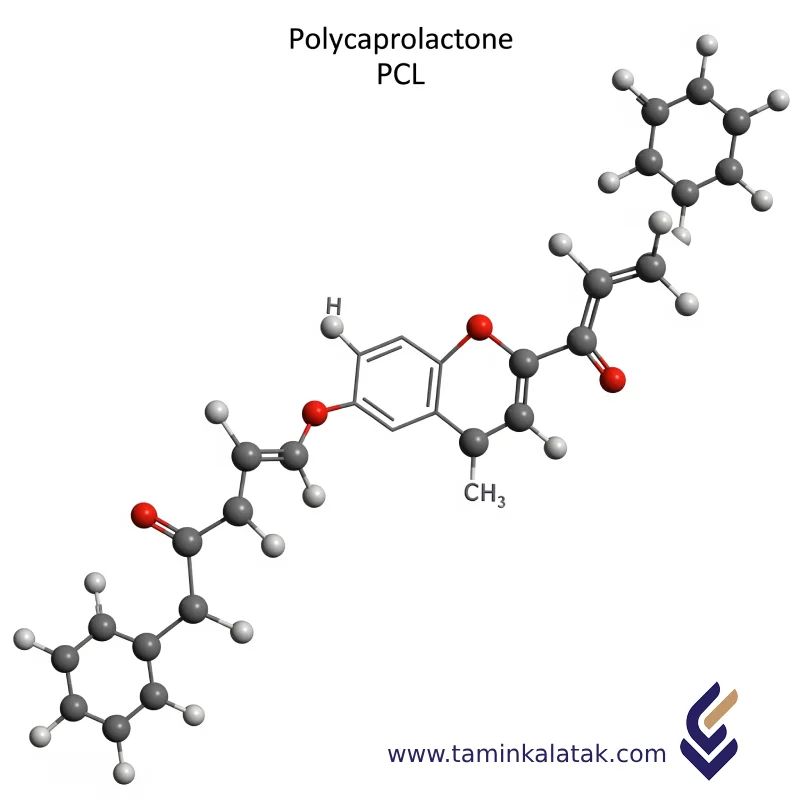

Structure of Polycaprolactone (PCL)

The chemical formula of its repeating unit is:

(C₆H₁₀O₂)ₙ

PCL has a semi-crystalline chain structure with flexible polymer chains and a relatively low melting temperature (around 60°C), allowing it to be easily blended with other polymers and reinforcing materials.

Properties of Polycaprolactone

-

Low melting temperature: approximately 58–63°C

-

Glass transition temperature (Tg): around –60°C

-

Excellent processability: suitable for injection molding, extrusion, and 3D printing

-

Biodegradability: decomposes under environmental or industrial composting conditions

-

Biocompatibility: suitable for medical and pharmaceutical applications

-

High flexibility: retains elasticity even at low temperatures

Applications of Polycaprolactone

-

Medical and pharmaceutical uses: absorbable sutures, drug delivery systems, tissue engineering scaffolds

-

3D printing and rapid prototyping: due to its low melting temperature and precise printability

-

Biodegradable products: compostable bags, packaging, and films

-

Polymer blending: used as an additive to improve flexibility or lower the melting point of other polymers such as PLA

Advantages of Polycaprolactone

-

Biodegradable and environmentally friendly

-

Flexible even at low temperatures

-

Excellent compatibility with other polymers

-

Non-toxic and safe for medical applications

-

Good dimensional stability during processing

Disadvantages of Polycaprolactone

-

Relatively high production cost compared to common polymers

-

Low melting temperature, making it unsuitable for high-temperature applications

-

Slow degradation rate under natural conditions (without industrial composting)

-

Lower mechanical strength compared to some thermoplastics such as PET or ABS