Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A thermoplastic is a type of plastic polymer that becomes moldable or flexible at a certain temperature and solidifies upon cooling. This property allows it to be repeatedly softened by heating and hardened by cooling without significant chemical change.

Polyarylate (PAR)

Polyarylate (PAR) is a type of high-performance aromatic polyester known for its excellent thermal stability, mechanical strength, and resistance to chemicals and UV radiation. It is commonly used in engineering applications where durability and heat resistance are required.

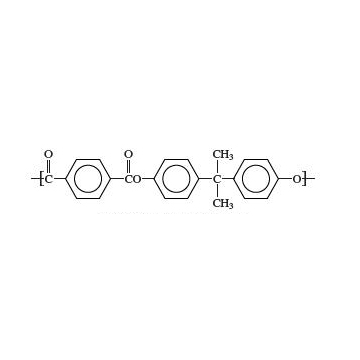

Structure

Polyarylate (PAR) is a high-performance thermoplastic polymer composed of repeating aromatic ester units in its backbone. Its structure consists of aromatic rings (benzene) connected by ester (-COO-) linkages, giving it excellent thermal and mechanical properties. The presence of these rigid benzene rings enhances the polymer’s strength, dimensional stability, and resistance to heat and UV radiation. Unlike aliphatic polyesters, which have flexible carbon chains, the rigid aromatic backbone of polyarylates prevents easy molecular rotation, making the material more heat-resistant and mechanically robust. A common type of polyarylate is based on bisphenol A (BPA) and terephthalic or isophthalic acid, forming a polymer with a high glass transition temperature and excellent durability. This unique structure makes polyarylates ideal for applications requiring transparency, heat resistance, and chemical stability, such as optical lenses, automotive parts, and electronic components.

Properties

Polyarylate (PAR) exhibits a combination of high thermal stability, mechanical strength, and chemical resistance, making it a valuable engineering thermoplastic. It has a high glass transition temperature (Tg) of around 180°C, allowing it to retain its shape and strength under elevated temperatures. Its excellent mechanical properties, including high tensile strength and toughness, make it resistant to wear and impact. Additionally, PAR has outstanding UV and weather resistance, preventing degradation when exposed to sunlight, making it suitable for outdoor applications. The polymer is also chemically resistant to oils, acids, and solvents, ensuring durability in harsh environments. Many grades of polyarylate are optically transparent, making them useful for lenses and display applications. Furthermore, it exhibits good dimensional stability and low creep, ensuring reliability in precision applications like electronic components and automotive parts. These properties collectively make PAR an ideal material for high-performance applications where strength, heat resistance, and durability are essential.

Applications of Polyarylate (PAR):

- Electronics & Electrical Components – Used in connectors, insulators, and circuit boards due to its heat and electrical resistance.

- Automotive Parts – Ideal for components exposed to high temperatures and mechanical stress.

- Aerospace Industry – Used in structural components for its lightweight and high durability.

- Optical Lenses & Displays – Some grades are optically clear, making them suitable for eyewear, camera lenses, and LCD panels.

- Medical Devices – Resistant to sterilization methods and biocompatible for certain medical applications.

- Industrial Machinery – Used in gears, seals, and mechanical components requiring high strength and wear resistance.

- Consumer Goods – Found in high-end cookware, protective coatings, and UV-resistant outdoor products.

Advantages of Polyarylate (PAR):

- High heat resistance – Maintains strength at elevated temperatures.

- Excellent mechanical strength – High tensile strength and impact resistance.

- UV and weather resistance – Ideal for outdoor applications without degradation.

- Good chemical resistance – Withstands exposure to oils, acids, and solvents.

- Optical clarity – Some grades are transparent, useful for lenses and displays.

- Dimensional stability – Low creep and high rigidity for precision applications.

Disadvantages of Polyarylate (PAR):

- Expensive – Higher cost compared to conventional plastics.

- Difficult processing – Requires specialized equipment and high processing temperatures.

- Brittle in some conditions – May be prone to stress cracking under certain loads.

Limited availability – Less commonly used than other engineering plastics, leading to fewer commercial grades.

Applications

| Applications | , , , , |

|---|

PAR

| Products | MFI (g/10 min) | Density (g/Cm3) | Process Method | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| PAR | 5–20 | 1.20–1.25 | Injection Molding Extrusion Blow Molding Thermoforming | Optical lenses Automotive headlamp lenses Electronic connectors Medical device housings Food packaging films Household appliance components Sports equipment |