Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Engineering polymers are high-performance plastics that exhibit superior mechanical, thermal, chemical, and electrical properties compared to standard commodity plastics.

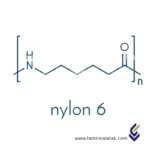

Nylon 6

Nylon 6 is a synthetic engineering thermoplastic belonging to the polyamide (PA) family. It is widely used for its high strength, durability, thermal resistance, and chemical stability. Nylon 6 is synthesized from a single monomer, caprolactam, through ring-opening polymerization. This makes Nylon 6 easier to produce and process.

Properties

Nylon 6 is a strong, lightweight, and durable engineering thermoplastic known for its excellent mechanical and thermal properties. It has high tensile strength, toughness, and impact resistance, making it suitable for demanding applications. It also exhibits good wear resistance, low friction, and excellent abrasion resistance, which enhances its longevity in mechanical parts. Nylon 6 has a melting point of approximately 220°C and maintains stability over a wide temperature range. It offers good chemical resistance to oils, greases, and many solvents but is sensitive to strong acids and bases. One of its notable characteristics is its high moisture absorption, which can affect its mechanical strength and dimensional stability. Nylon 6 also has good electrical insulating properties, making it useful in electrical and electronic applications. Additionally, it is easily processable through injection molding, extrusion, and fiber spinning, allowing for its widespread use in textiles, automotive components, and industrial applications.

Structure

Nylon 6 is a synthetic polymer belonging to the polyamide family, characterized by its repeating units derived from caprolactam through a ring-opening polymerization process. The molecular structure of Nylon 6 consists of a linear chain of amide (–CONH–) linkages interspersed with six-carbon alkyl segments, forming a highly regular and symmetrical backbone that contributes to its notable mechanical strength, thermal stability, and chemical resistance. Unlike Nylon 6,6, which is synthesized from two different monomers, Nylon 6 is synthesized from a single monomer, ε-caprolactam, which undergoes polymerization through successive opening of the lactam ring, resulting in a continuous chain structure. The presence of hydrogen bonding between adjacent polymer chains enhances intermolecular interactions, leading to high crystallinity and improved tensile properties. This structural arrangement imparts Nylon 6 with desirable characteristics such as high flexibility, durability, and resistance to abrasion, making it widely utilized in textiles, engineering plastics, and industrial applications.

Applications of Nylon 6

- Textiles and Fabrics: Nylon 6 is widely used in the textile industry to produce items such as hosiery, swimwear, activewear, and undergarments due to its elasticity, strength, and smooth texture.

- Industrial Uses: Its high tensile strength and abrasion resistance make Nylon 6 suitable for manufacturing ropes, fishing nets, conveyor belts, and tire cords.

- Automotive Components: Nylon 6 is utilized in producing various automotive parts, including gears, bearings, and under-the-hood components, because of its durability and thermal stability.

- Consumer Goods: Common household items like toothbrush bristles, combs, and kitchen utensils are often made from Nylon 6 due to its resilience and ease of molding.

- Engineering Plastics: Nylon 6 is used in the production of engineering plastics for applications such as gears, bearings, and other mechanical components, owing to its strength and wear resistance.

Advantages of Nylon 6

- High Strength and Durability: Nylon 6 exhibits excellent tensile strength, making it suitable for products requiring long-lasting performance.

- Flexibility and Elasticity: The material offers good flexibility and can return to its original shape after stretching, which is beneficial for textile applications.

- Chemical Resistance: Nylon 6 is resistant to a wide range of chemicals, including oils and solvents, enhancing its suitability for various industrial applications.

- Thermal Resistance: With a high melting point, Nylon 6 can withstand elevated temperatures, making it appropriate for applications involving heat exposure.

- Lightweight: Nylon 6 is lighter than many metals, which is advantageous in applications where weight reduction is desired.

Disadvantages of Nylon 6

- Moisture Absorption: Nylon 6 is hygroscopic and can absorb moisture from the environment, leading to dimensional changes and potential degradation of mechanical properties.

- UV Sensitivity: Prolonged exposure to ultraviolet light can cause Nylon 6 to degrade, leading to discoloration and loss of strength.

- Lower Impact Resistance: Compared to some other engineering plastics, Nylon 6 may exhibit lower impact resistance, which could limit its use in high-impact applications.

- Processing Challenges: Nylon 6 requires careful control during processing, as it is sensitive to moisture and can degrade if not properly dried before molding.

Applications

| Applications | , , , , |

|---|

Nylon 6

| Products | Grade | Density(g/Cm3) | Applications | process method | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| Nylon 6 | Nylatron® MD | 115,00 | Bearings and Bushings Gears and Sprockets Wear Pads and Strips Rollers and Sheaves Valve Seats and Seals | Injection Molding Extrusion Machining | ||

| Nylon 6 | Nylatron® NSM | 114,00 | Wear Pads and Strips Rollers and Sheaves Valve Seats and Seals | Casting Machining | ||

| Nylon 6 | Ertalon® LFX | 1.135,00 | Wear Pads and Strips Rollers and Sheaves Valve Seats and Seals | Casting Machining |