Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or fomed. General-purpose polystyrene is clear, hard, and brittle. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature.and also It has wide applications in various industries including packaging, construction, and automotive.

High Impact PolyStyrene (HIPS)

High Impact Polystyrene, also known as HIPS or toughened polystyrene, is a type of thermoplastic polymer produced by combining general-purpose polystyrene (GPPS) with elastomers such as polybutadiene. Rubber-reinforced polystyrene exhibits greater impact resistance compared to pure polystyrene while retaining the main advantages of polystyrene, such as flexibility and cost-effectiveness. This material is widely used in everyday equipment. The polymer is usually synthesized through free-radical bulk polymerization.

Structure of High Impact Polystyrene

Chemically, polystyrene is a long-chain hydrocarbon in which alternating carbon centers are attached to phenyl groups (benzene rings). The chemical formula of polystyrene is (C₈H₈)ₙ; it consists of monomers containing carbon and hydrogen atoms.

The material’s properties are determined by short-term Van der Waals attractions between the polymer chains. Since the molecules are long-chain hydrocarbons composed of thousands of atoms, the overall intermolecular attraction is strong. When heated (or rapidly deformed due to its viscoelastic and thermal insulating characteristics), the chains gain more mobility and slide past each other.

This weak intermolecular bonding (in contrast to the strong hydrocarbon backbone) gives the material its flexibility and elasticity. The ability of the system to deform at temperatures above its glass transition temperature allows polystyrene (and, generally, thermoplastic polymers) to soften easily when heated and be molded into various shapes.

In High Impact Polystyrene (HIPS), some polybutadiene rubber is added to the chains. This rubber phase is dispersed within the polystyrene matrix. These dispersed rubber particles act as “shock absorbers,” preventing crack propagation through the polymer.

Properties of High Impact Polystyrene (HIPS)

HIPS combines a range of properties that make it a versatile and widely used material. The key advantages include:

High Impact Strength

By adding butadiene rubber modifiers to standard PS, HIPS becomes highly impact-resistant. This makes it ideal for producing components prone to breakage, such as household appliances and toys.

Excellent Molding and Processability

Due to its low melting point, HIPS can easily be processed through various methods, including injection molding and thermoforming. This property reduces production costs and increases manufacturing efficiency.

Printing Applications

The matte and uniform surface of HIPS enables excellent ink adhesion, making it ideal for printed products, signboards, and advertising packaging.

High Colorability

This polymer material is highly compatible with color masterbatches and can be customized with a wide range of colors—an advantage particularly useful in decorative or consumer goods industries.

Cost-Effectiveness

Compared with other engineering plastics, HIPS is more affordable, making it an economical and popular choice for mass production of parts with good mechanical properties.

Chemical Resistance

HIPS resists weak acids, alcohols, and saline solutions, as well as oils and greases, making it suitable for diverse environments (though it is sensitive to organic solvents).

Compatibility with Additives

HIPS can easily be blended with additives such as antistatic agents, white masterbatch, UV stabilizers, and flame retardants to achieve enhanced properties.

According to ASTM standards, HIPS exhibits a tensile strength of 24.8 MPa (3,600 psi) and a tensile modulus of 1.8 GPa (261 ksi), allowing it to withstand sufficient mechanical stress—making it ideal for packaging and many other products.

Applications of High Impact Polystyrene

From food stores to packaging factories and production lines, this versatile plastic is used across many sectors. Some common examples include:

-

Building applications, such as thermal and acoustic insulation and suspended ceilings.

-

Cutlery, including disposable knives, forks, and spoons used in the food industry.

-

Extruded profiles for exhibition stands and display structures.

-

Containers and trays for the packaging industry.

-

Pipes and lightweight profiles used in household products.

-

Injection-molded parts for assembling toys.

-

Due to its low cost and easy machinability, HIPS is often used as a substitute for die-cast metal in industrial applications.

-

HIPS is also used in transportation industries, forming part of various aircraft and automotive components.

Disadvantages of High Impact Polystyrene

-

HIPS is susceptible to degradation when exposed to many chemicals, including solvents, acids, and alkalis.

-

It exhibits low resistance to very low temperatures and may become brittle.

-

It has limited UV resistance, turning yellow and brittle upon prolonged sunlight exposure.

-

HIPS has poor flame resistance and can ignite easily.

Types of High Impact Polystyrene

HIPS (General Type)

The most commonly used type of high-impact polystyrene, known for its excellent impact resistance suitable for various applications.

HIPS 7240

A special grade of impact-resistant polystyrene produced by Tabriz Petrochemical Company, known for its excellent properties and wide industrial use.

HIPS 6045

Another grade produced by Tabriz Petrochemical Company, featuring strong mechanical characteristics.

Purchasing High Impact Polystyrene

As discussed, High Impact Polystyrene (HIPS) is one of the most widely used polymers in the industry.

If you are looking to purchase high-quality HIPS, we offer HIPS 7240 from reputable brands. These materials feature various Melt Flow Index (MFI) values, high softening points, and are suitable for injection molding and thermoforming processes. To place an order for your desired grade, simply contact our supply specialists.

For up-to-date HIPS pricing, contact our sales team to get the latest market rates.

✅ Direct supply and sale of certified High Impact Polystyrene

✅ Provision of technical analysis and MSDS

✅ Technical consultation for selecting the right grade

✅ Competitive pricing and fast delivery

Contact us to select the most suitable High Impact Polystyrene grade for your production needs.

Production Process of High Impact Polystyrene (HIPS)

High Impact Polystyrene is a widely used thermoplastic produced by modifying general-purpose polystyrene (GPPS) with elastomeric rubbers, especially polybutadiene. This modification enhances toughness, impact strength, and mechanical durability—making polystyrene suitable for applications requiring higher impact resistance.

Tamin Kala Tak Company, as a supplier of raw materials, provides various HIPS grades from reputable manufacturers to deliver high-quality, consistent final products to customers.

HIPS Manufacturing Stages

The production of HIPS in petrochemical and polymer plants generally includes the following steps:

1. Preparation of Styrene Monomer

-

Styrene monomer is obtained from the dehydrogenation of ethylbenzene.

-

High monomer purity (over 99%) is essential for achieving optimal final properties.

-

Stabilizers are added to prevent unwanted polymerization during storage.

2. Addition of Rubber (Polybutadiene)

-

About 5–10% polybutadiene is added to the styrene monomer.

-

The rubber is dissolved in the monomer to ensure proper dispersion during the reaction, forming a rubber phase within the polystyrene matrix.

3. Bulk or Solution Polymerization

-

The polymerization reaction is usually carried out through Bulk Polymerization or Solution Polymerization.

-

Radical initiators (such as peroxides) trigger the reaction.

-

During polymerization, rubber particles disperse within the polystyrene matrix, forming a two-phase structure responsible for improved impact resistance.

4. Reaction Completion and Separation

-

Once the desired polymerization degree is achieved, the reaction is terminated.

-

Solvents (in the solution process) and unreacted monomers are recovered and recycled.

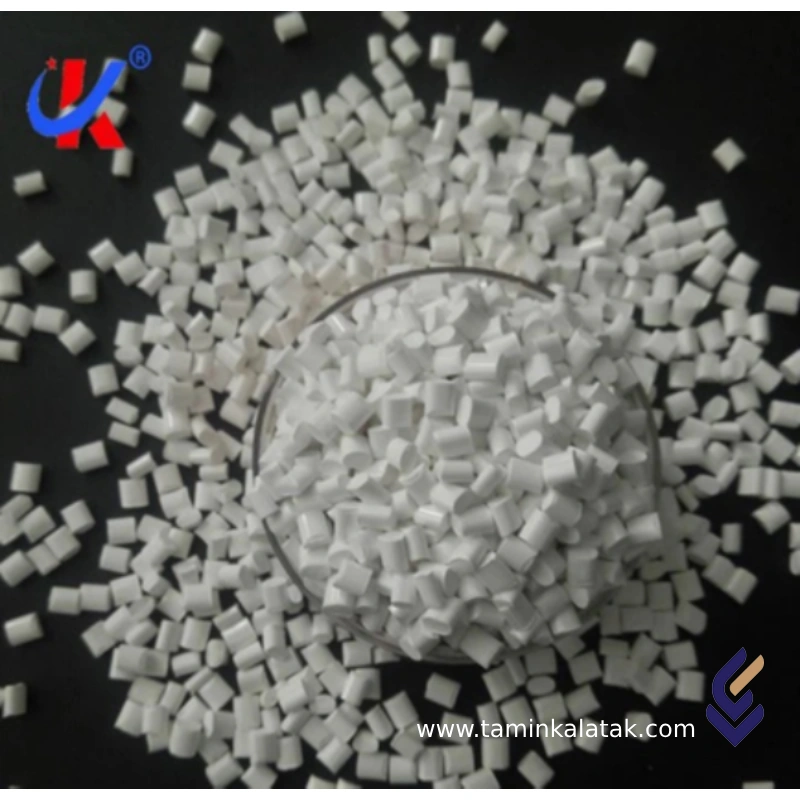

5. Pelletizing and Packaging

-

The molten polymer is extruded and cut into strands to form HIPS granules.

-

The granules are cooled, dried, and packed in multi-layer bags or jumbo bags.

FAQ – High Impact Polystyrene

1. What is the difference between High Impact Polystyrene and General Purpose Polystyrene?

HIPS is a type of thermoplastic polymer produced by adding butadiene rubber to general-purpose polystyrene (GPPS). This structural modification enhances impact resistance, flexibility, and mechanical stability compared to standard GPPS.

2. In which industries is High Impact Polystyrene used?

Due to its excellent moldability and impact strength, HIPS is used in:

-

Household appliance housings (e.g., refrigerators, TVs, vacuum cleaners)

-

Food and dairy packaging

-

Electronic equipment and light industrial parts

-

Toys and decorative products

3. What are the main advantages of High Impact Polystyrene?

-

High resistance to impact and bending

-

Excellent machinability, printability, and colorability

-

Easy processability in injection molding and thermoforming

-

Cost-effective compared to other high-performance thermoplastics

Applications

| Applications | , , , , |

|---|

HIPS

| prodact | Grade | MFI (g/10 min) | Density (g/cm3) | Vicat Softening Point 50°C/hr(1kg) | process metod | Applications / Description | Data Sheet | MSDS | Brochure |

|---|---|---|---|---|---|---|---|---|---|

| HIPS | 7240 | 4.5 | 1.04 | 94-97 | extrusion ,thermoforming, injection molding | Industrial parts, food packaging | Download | ||

| HIPS | 8350 | 4.5 | 1.04 | 96 | extrusion ,thermoforming, injection molding | automotive industry , electronic industry, packaging industry | |||

| HIPS | 3630 | 15 | 1.05 | 90 | extrusion ,thermoforming, injection molding | Bathroom accessories, clothes hangers | |||

| HIPS | 4240 | 3.5 | 1.05 | 97 | extrusion ,thermoforming, injection molding | Sales cups, extruded profiles | |||

| HIPS | 6630 | 13 | 1.03-1.06 | 91 | extrusion ,thermoforming, injection molding | Computer keyboard, toys, pulleys | |||

| HIPS | WT 1235 | 5 | 1.04 | 96 | extrusion ,thermoforming, injection molding | Toys, cabinets, clocks |