Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A compound is a polymer blend mixed with additives, fillers, and reinforcements to achieve specific properties for end-use applications. A masterbatch is a concentrated mixture of additives or pigments in a carrier resin, used to enhance plastics without altering their base properties.

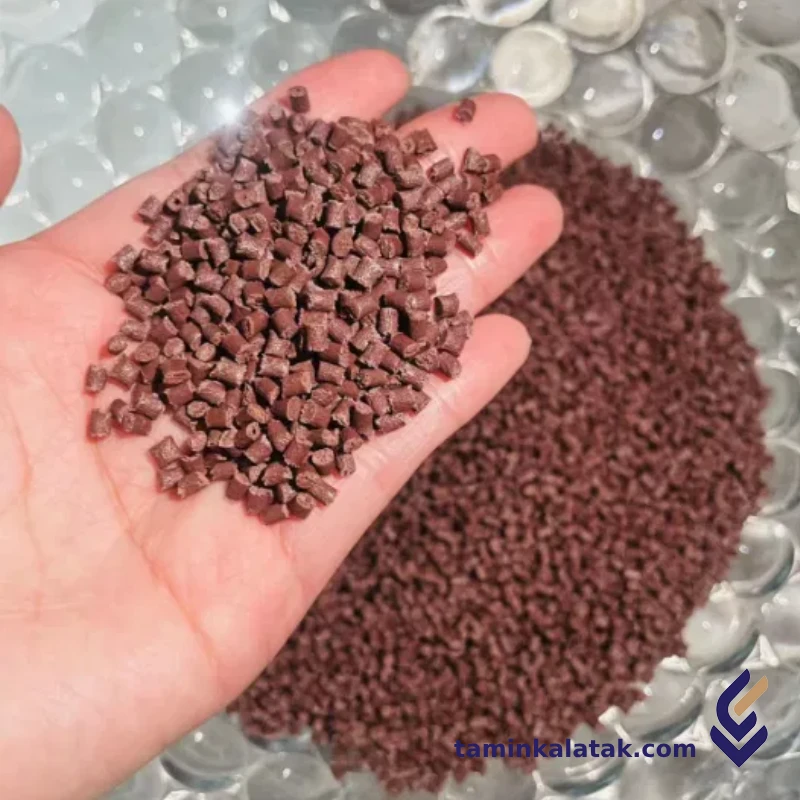

Flame-retardant polyamide fiber compounds

Flame-retardant polyamide (PA) fiber compounds are specialized materials designed to resist ignition, reduce flame spread, and minimize smoke production. These compounds are widely used in industries such as automotive, electrical, electronics, and textiles, where fire safety is critical.

Structure

Flame-retardant polyamide fiber compounds are engineered materials that combine polyamide polymers with flame-retardant additives to enhance fire resistance while maintaining mechanical and thermal stability. The base polymer, often PA6 or PA66, provides durability, flexibility, and high melting resistance, while the flame-retardant components are incorporated to inhibit ignition and slow down combustion. These additives can be halogen-based, such as brominated compounds, or halogen-free, including phosphorus, nitrogen, and inorganic fillers like aluminum diethylphosphinate or magnesium hydroxide. The molecular structure of these compounds is designed to promote charring, reduce heat release, and suppress smoke generation. In some formulations, synergists like melamine-based compounds or nanofillers are used to enhance flame-retardant efficiency. The final structure of the compound depends on the type and dispersion of these additives within the polyamide matrix, ensuring a balance between flame resistance, mechanical integrity, and processability for applications in textiles, electronics, and automotive components.

Properties

Flame-retardant polyamide fiber compounds exhibit a combination of thermal stability, mechanical strength, and fire resistance, making them suitable for high-performance applications. These materials are designed to meet stringent fire safety standards, often achieving UL 94 V-0 or V-1 ratings, which indicate their ability to self-extinguish quickly after ignition. They offer low flammability, reduced heat release, and minimal smoke and toxic gas emissions, which are essential for applications in public spaces and enclosed environments. Their mechanical properties, including high tensile strength, flexibility, and abrasion resistance, remain largely unaffected by the incorporation of flame-retardant additives. Additionally, they provide excellent resistance to chemicals, moisture, and heat, making them ideal for demanding environments such as automotive, electrical, and industrial applications. The presence of halogen-free additives, such as phosphorus or nitrogen-based compounds, enhances environmental compatibility while maintaining effective flame retardancy. These properties ensure that flame-retardant polyamide fiber compounds provide both safety and durability without compromising on performance.

Applications

- Automotive: Wire harnesses, connectors, under-the-hood components

- Electronics: Circuit breaker housings, switch components, insulation materials

- Textiles: Protective clothing, carpets, upholstery (aviation, military, public transport)

- Industrial: Conveyor belts, high-performance fabrics, filtration systems

Advantages

- Excellent flame resistance, meeting UL 94 V-0 or V-1 standards

- High mechanical strength and durability

- Good chemical and thermal resistance

- Low smoke and toxicity emissions, especially in halogen-free formulations

- Suitable for demanding applications requiring both safety and performance

Disadvantages

- Higher production costs compared to non-flame-retardant polyamides

- Potential reduction in mechanical properties due to additive incorporation

- Processing challenges, such as increased viscosity and compatibility issues with certain manufacturing techniques

Applications

| Applications | , , , |

|---|

Flame-retardant polyamide fiber compounds

| Products | MFI (g/10 min) | Density (g/Cm3) | Process Method | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| Flame-retardant polyamide fiber compounds | 5-30 | 1.1-1.6 | Injection Molding Extrusion Blow Molding Compounding | Automotive Electronics & Electrical Textiles Industrial |