Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A thermoplastic is a type of plastic polymer that becomes moldable or flexible at a certain temperature and solidifies upon cooling. This property allows it to be repeatedly softened by heating and hardened by cooling without significant chemical change.

TetrafluoroEthylene/perfluoroPropylene copolymers (FEP)

Tetrafluoroethylene/Perfluoropropylene (FEP) is a melt-processable fluoropolymer composed of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP). It belongs to the family of fluoropolymers and shares many properties with polytetrafluoroethylene (PTFE), but with enhanced processability due to the incorporation of HFP.

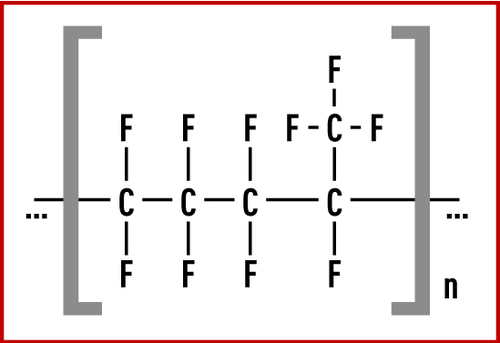

Structure

The structure of Tetrafluoroethylene/Perfluoropropylene (FEP) copolymer consists of a randomly distributed backbone of tetrafluoroethylene (TFE) and hexafluoropropylene (HFP) monomer units. The TFE units provide the high thermal and chemical resistance characteristic of fluoropolymers, while the HFP units introduce branching that disrupts crystallinity, enhancing flexibility and melt processability. The polymer chain is composed of repeating –CF₂–CF₂– segments from TFE and –CF₂–CF(CF₃)– segments from HFP, where the bulky trifluoromethyl (-CF₃) groups reduce intermolecular forces, lowering the melting point compared to PTFE. This molecular architecture results in a copolymer with excellent non-stick properties, chemical inertness, and transparency while being more easily processed using conventional melt-processing techniques.

Properties

Tetrafluoroethylene/Perfluoropropylene (FEP) copolymers exhibit a unique combination of thermal stability, chemical resistance, electrical insulation, and mechanical flexibility. They can withstand continuous exposure to high temperatures up to 200°C (392°F) while maintaining their structural integrity. FEP is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents, making it ideal for harsh environments. Its non-stick and low-friction surface prevents adhesion and contamination, similar to PTFE. Unlike PTFE, FEP is melt-processable, allowing for fabrication through extrusion, injection molding, and blow molding. It also possesses excellent electrical insulating properties, with a low dielectric constant and high breakdown voltage, making it a preferred choice for wire and cable insulation. Additionally, FEP is optically transparent, resistant to UV radiation, and does not degrade under prolonged exposure to environmental factors, further enhancing its suitability for industrial, aerospace, and medical applications.

Applications of FEP Copolymers:

- Wire & Cable Insulation: Used in aerospace, automotive, and telecommunications due to high heat and chemical resistance.

- Chemical Processing Equipment: Linings for pipes, valves, and tanks in harsh chemical environments.

- Medical Tubing & Catheters: Biocompatible and resistant to sterilization processes.

- Food & Beverage Industry: Non-stick coatings for cooking equipment and food processing machinery.

- Semiconductor Industry: Used in chip manufacturing equipment due to high purity and chemical resistance.

- Heat Shrink Tubing: Provides electrical insulation and protection in extreme environments.

- Optical Fiber Coatings: Protects fibers in harsh conditions without affecting signal transmission.

- Laboratory Equipment: Used for beakers, flasks, and other chemical-resistant lab tools.

Advantages of FEP Copolymers:

- Excellent Chemical Resistance: Inert to most acids, bases, and solvents.

- High Thermal Stability: Can withstand temperatures up to ~200°C (392°F).

- Non-Stick Properties: Similar to PTFE (Teflon), preventing adhesion of substances.

- Low Friction: Reduces wear in moving parts and improves efficiency.

- Electrical Insulation: High dielectric strength makes it ideal for electrical applications.

- Transparent & UV Resistant: Can be used in optical and outdoor applications.

- Biocompatibility: Safe for medical and food-contact applications.

Disadvantages of FEP Copolymers:

- Lower Mechanical Strength: Weaker than PTFE in terms of tensile strength and wear resistance.

- Higher Cost: More expensive than common plastics like PVC or polyethylene.

- Limited Temperature Resistance: Slightly lower thermal stability than PTFE.

- Difficult Processing: Requires specialized molding and extrusion techniques.

- Fluorine Emission on Decomposition: Can release toxic fumes if overheated beyond its thermal limits.

Applications

| Applications | , , , , , |

|---|

FEP

| Products | MFI (g/10 min) | Density (g/Cm3) | Process Metod | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| FEP | 5-30 | 2.12 to 2.17 | Extrusion Injection Molding Compression Molding Rotational Molding Blow Molding Welding & Heat Sealing Coating & Lamination | Wire and cable insulation Semiconductor components Medical tubing Fluid handling systems Automotive fuel systems Chemical processing equipment Food processing machinery Aerospace components |