Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

HDPE stands for High-Density Polyethylene, which is one of the most widely used materials in the world and is used in various industries due to its unique properties.

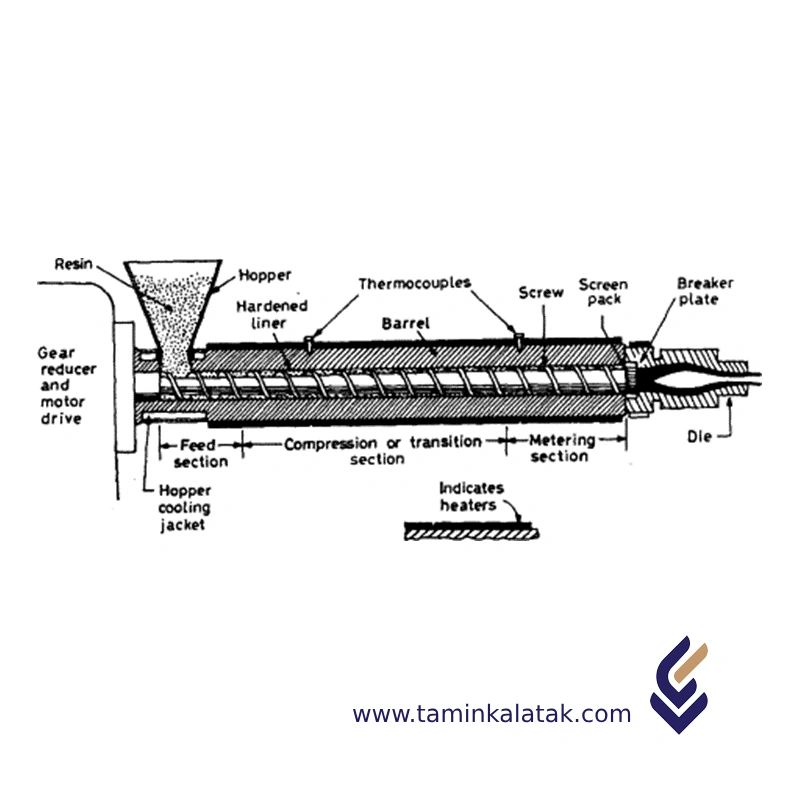

Extrusion

The extrusion process is basically designed to continuously convert a soft material into a particular form. The heart of this processing/fabrication machine is a screw conveyer. It carries the cold plastic material (in granular or powdered form) forward by the action of the screw and squeezes it, and, with heat from external heaters and the friction of viscous flow, changes it to a molten stream (refer to Figure 1). As it does this, it develops pressure on the material, which is highest right before the molten plastic enters the die. The screen pack, consisting of a number of fine or coarse mesh gauzes supported on a breaker plate and placed between the screw and the die, filter out dirt and unfused polymer lumps. The pressure on the molten plastic forces it through an adapter and into the die, which dictates the shape of the final extrudate.

Hot extrusion

Hot extrusion is a hot working process, which means it is done above the material’s recrystallization temperature to keep the material from work hardening and to make it easier to push the material through the die. Most hot extrusions are done on horizontal hydraulic presses that range from 230 to 11,000 metric tons . Pressures range from 30 to 700 MPa , therefore lubrication is required, which can be oil or graphite for lower temperature extrusions, or glass powder for higher temperature extrusions. The biggest disadvantage of this process is its cost for machinery and its upkeep.

Cold extrusion

Cold Extrusion is a push-through compressive forming process with the starting material (billet/slug) at room temperature. During the process, however, the deforming material undergoes deformation heating (conversion of deformation work to heat) to several hundred degrees. Typically, a punch is used to apply pressure to the billet enclosed, partially or completely, in a stationary die.

Advantages of Extrusion:

- Cost-effective for large-scale production with minimal waste.

- Versatile: Supports various materials and shapes.

- Customizable: Additives and design flexibility.

- Consistent quality and scalable production.

- Energy-efficient and integrates with other processes.

Disadvantages of Extrusion:

- Material limitations: Not all polymers are suitable.

- High setup costs: Equipment and dies are expensive.

- Dimensional variability: Cooling shrinkage and die swell.

- Shape limitations: Intricate designs are challenging.

- Quality control issues: Surface defects and material inconsistencies.

- Post-processing needs: Cutting, finishing, or coating required.

- Environmental concerns: Energy use and plastic waste.

Application of extrusion

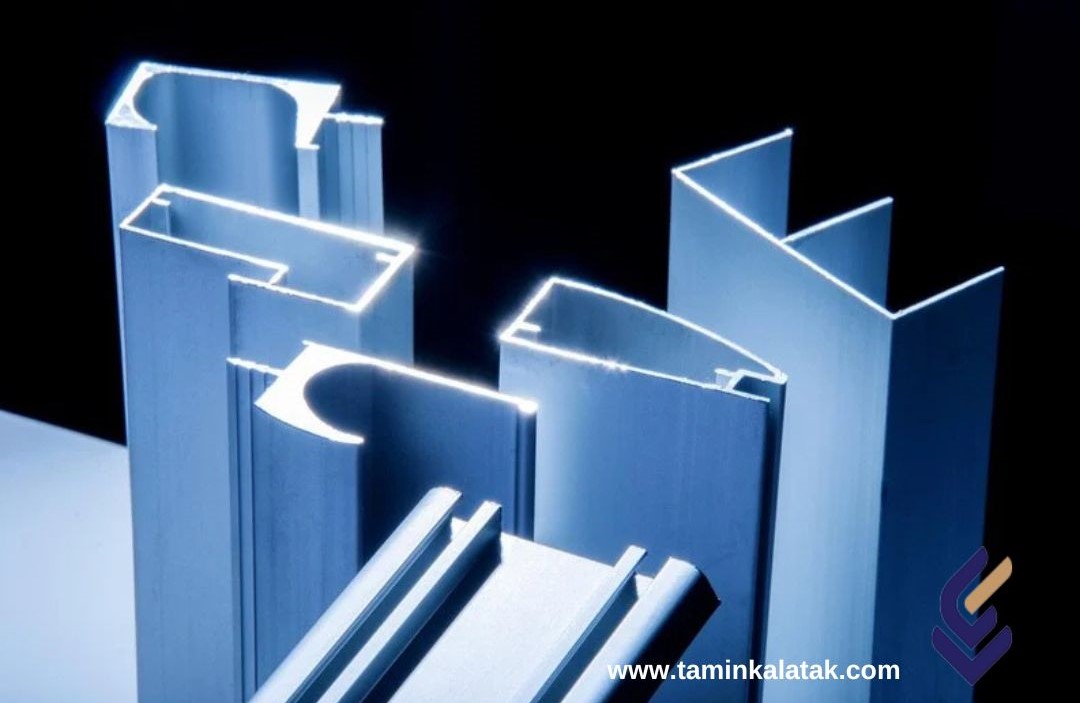

1.Construction Industry

- Pipes and tubing (e.g., PVC pipes, drainage systems).

- Window and door profiles (e.g., uPVC frames).

- Insulation materials (e.g., foam boards, weather seals).

2.Packaging Industry

- Plastic films and sheets (e.g., food packaging, shrink wraps).

- Containers and trays.

3.Automotive Industry

- Seals and gaskets.

- Wire and cable insulation.

- Interior trims and protective sheathing.

4.Consumer Goods

- Straws, ropes, and garden hoses.

- Plastic profiles for furniture or appliances.

5.Electrical and Electronics

- Wire and cable coatings.

- Conduits for electrical wiring.

6.Medical Field

- Catheters, tubing, and other medical-grade profiles.

7.Industrial Applications

- Conveyor belts and guides.

- Protective linings for machinery.

8.Agriculture

- Irrigation tubing and films.

- Greenhouse covers.

Polymer extrusion is versatile, making it crucial in industries requiring continuous, customizable plastic products.

Applications

HDPE Extrusion (EN)

| Prodact | Grade | MFI | Density (g/cm3) | Process Metod | Application / Description | Description | Data Sheet | MSDS | Brochure |

|---|---|---|---|---|---|---|---|---|---|

| HDPE PE80 | Ex3 | 0.2–1.0 g/10 min (190°C/2.16 kg) | 0.94–0.96 | Extrusion ,Injection Molding,Blow molding,Rotational molding | Water and gas pipes, chemical storage tanks, fittings, and conduits | ||||

| HDPE PE100 | CRP 100 B | 0.25–0.45 g/10 min (190°C/5 kg) | 0.947–0.960 | Extrusion, injection molding, blow molding | Pipes, fittings, tanks, and industrial uses | ||||

| HDPE PE100 | CRP 100 N | 0.20–0.45 g/10 minutes (190°C/5 kg) | 0.95–0.96 | Extrusion, injection molding, blow molding, rotational molding | Pipes, fittings, chemical tanks, industrial uses | ||||

| Extrusion HDPE | HBM 4265 | 0.25–0.40 g/10 min (190°C/5 kg) | 0.950–0.960 g/cm³ | Extrusion | Pipes, protective liners, conduits, and industrial applications | ||||

| Extrusion HDPE | HBM 4261A | 0.20–0.40 g/10 min (190°C/5 kg) | 0.950–0.958 | Extrusion | Pipes, protective liners, conduits, and industrial systems | HBM 4261A is a high molecular weight, high-density polyethylene with broad molecular weight distribution specially developed for producing automotive fuel tank. This grade, which is produced by 1-hexene co-monomer, offers a very good creep strength, good processability, excellent environmental stress cracking resistance (ESCR) and stiffness. HBM 4261A has been manufactured under Basell license. | |||

| Extrusion HDPE | HBM 5510 | 0.30–0.50 g/10 min (190°C/5 kg) | 0.950–0.960 | Extrusion | Pipes, protective liners, conduits, industrial applications, infrastructure | HBM 5510 is a high density polyethylene, specially developed for large parts blow molding. This grade, which is produced by 1-hexene as a co-monomer, offers high stiffness, good processability, excellent parison melt strength and good ESCR. HBM 5510 has been manufactured under Basell license. | |||

| HDPE PE80 | HEX4460 PE80+ | ~0.3–0.6 g/10 min (at 190°C and 2.16 kg load) | ~0.940–0.950 | Extrusion / Injection Molding (optional) | Water and Gas Pipelines / Sewage and Drainage Systems / Irrigation Systems / Industrial Applications | HEX 4460 PE80+ is a high molecular weight, high-density polyethylene (HDPE) with high melt viscosity for extrusion. This grade, which is produced by 1-hexene co-monomer, is classified as PE 80+ and provides excellent stress crack resistance properties (ESCR) combined with very good long-term hydrostatic strength and good processability. | |||

| Extrusion HDPE | HBM 5520 | ~0.30–0.40 g/10 min (at 190°C and 2.16 kg load) | ~0.950–0.960 | Extrusion /Injection Molding (optional) | Films and Sheets / Pipes and Tubes / Blow Molding / Industrial Parts and Fittings | HBM 5520 is a high density polyethylene with medium molecular weight. This grade which is produced by 1-hexene as a co-monomer, offer excellent combination of toughness, stress cracking resistance, good mechanical properties and good processability. HBM 5520 is recommended for multipurpose blow molding process. HBM 5520 has been manufactured under Basell license. | |||

| Extrusion HDPE | HBM 5020 | ~0.20–0.50 g/10 min (at 190°C and 2.16 kg load) | ~0.950–0.960 | Extrusion / Injection Molding (optional) | Films and Sheets / Pipes and Tubes / HBM 5020 / Industrial Components / Consumer Goods | HBM 5020 is a high density polyethylene with broad molecular weight distribution, specially developed for small blow molded bottles. This grade which is produced by 1-hexene as a co-monomer, offer high stiffness, easy flow, very good ESCR, chemical resistance and sufficient impact strength. HBM 5020 is recommended for multipurpose blow molding process. HBM 5020 has been manufactured under Basell license. | |||

| HDPE PE100 | HMCRP100N (PE100) | ~0.25–0.35 g/10 min (at 190°C and 2.16 kg load) | ~0.945–0.955 | Extrusion / Injection Molding (Fittings) / Blow Molding and Sheet Extrusion | Pressure Pipes / Fittings and Accessories / Underground Piping Systems / High-Pressure Transport Systems | HM-CRP100N (PE100) is a natural pipe grade resin which is manufactured by suspension polymerization of ethylene monomer, HM-CRP100N(PE100) is a bi-modal high density polyethylene with 1-Butene as comonomer. | |||

| HDPE PE100 | PE100 Black | ~0.25–0.35 g/10 min (at 190°C and 2.16 kg load) | ~0.945–0.960 | Pipe Extrusion / Injection Molding / Blow Molding and Sheet Extrusion / | Pressure Pipes / Gas Piping / Fittings and Accessories / Underground Piping Systems / Irrigation Systems | HM-CRP100 Black is a black pipe grade resin (PE100) which is manufactured by suspension polymerization of ethylene monomer. HM-CRP100 Blue is a bi-modal high density polyethylene with 1-Butene as comonomer. | |||

| HDPE PE80 | HM-5010T2N(EX3) | ~0.15–0.25 g/10 min (at 190°C and 2.16 kg load) | ~0.940–0.950 | Extrusion / Injection Molding (in some cases) / Blow Molding | Pressure pipes / Fittings and Components / Underground Piping Systems / Pressure-Rated Systems | HM-5010T2N (EX3) is a pipe grade resin which is manufactured by suspension polymerization of ethylene monomer. HM-5010T2N (EX3) is a bi-modal high density polyethylene with 1-Butene as comonomer. |