Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

A thermoplastic is a type of plastic polymer that becomes moldable or flexible at a certain temperature and solidifies upon cooling. This property allows it to be repeatedly softened by heating and hardened by cooling without significant chemical change.

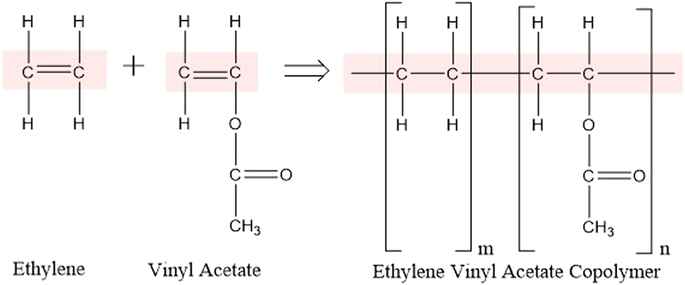

Ethylene Vinyl Acetate/ VAC- copolymers (EVA)

Ethylene Vinyl Acetate (EVA) is a copolymer composed of ethylene and vinyl acetate (VAC). The properties of EVA vary depending on the ratio of these two components, with vinyl acetate content typically ranging from 1% to 40% by weight.

Structure

Ethylene Vinyl Acetate (EVA) is a copolymer composed of ethylene and vinyl acetate (VAC) monomers, with its structure characterized by randomly distributed vinyl acetate units within a polyethylene-like backbone. The proportion of vinyl acetate in the copolymer significantly influences its properties, with lower vinyl acetate content (typically below 10%) resulting in a more rigid, polyethylene-like material, while higher vinyl acetate content (above 40%) leads to a more rubbery and flexible structure. The presence of vinyl acetate disrupts the crystallinity of polyethylene, enhancing the copolymer’s flexibility, impact resistance, and transparency. EVA exhibits a balance between thermoplastic and elastomeric properties, making it widely used in applications such as adhesives, foams, films, and footwear. Its molecular structure provides excellent toughness, stress-crack resistance, and adhesion to various substrates, making it a versatile polymer in multiple industries.

Properties

Ethylene Vinyl Acetate (EVA) copolymers exhibit a unique combination of properties that vary based on the vinyl acetate (VAC) content. They offer excellent flexibility, elasticity, and toughness, with higher VAC content leading to increased softness, transparency, and impact resistance. EVA has low-temperature resistance, maintaining flexibility even at sub-zero temperatures, and demonstrates good stress-crack resistance. It is also lightweight, has a low density, and provides excellent adhesion to various substrates, making it ideal for adhesives and coatings. Additionally, EVA is resistant to UV radiation and environmental stress, contributing to its durability in outdoor applications. It has good chemical resistance to water, oils, and certain solvents, though it may degrade under high temperatures or prolonged exposure to strong chemicals. The copolymer is also non-toxic, making it suitable for medical and food-contact applications. Its thermal and electrical insulation properties further enhance its versatility in industrial, packaging, and footwear applications.

Applications of Ethylene Vinyl Acetate (EVA) Copolymers:

- Footwear: Used in midsoles, insoles, and outsoles for cushioning and flexibility.

- Adhesives: Hot melt adhesives in packaging, bookbinding, and woodworking.

- Foams: Sports mats, yoga mats, and padding materials.

- Packaging: Film applications for food packaging and medical films.

- Automotive: Interior trims, soundproofing, and under-the-hood components.

- Solar Panels: Encapsulation of photovoltaic cells for durability and insulation.

- Wire & Cable Insulation: Used in electrical applications due to flexibility and insulation properties.

- Toys & Consumer Goods: Soft, flexible materials for safety and durability.

Advantages of EVA Copolymers:

- Flexibility & Softness: Offers rubber-like elasticity and comfort.

- Lightweight: Reduces overall product weight while maintaining durability.

- Good Adhesion: Bonds well with various substrates, making it ideal for adhesives.

- Weather & UV Resistance: Suitable for outdoor applications like solar panels and footwear.

- Chemical Resistance: Resists many chemicals, oils, and solvents.

- Low-Temperature Performance: Maintains flexibility in cold conditions.

- Non-Toxic & Safe: Used in food packaging and medical applications.

Disadvantages of EVA Copolymers:

- Lower Heat Resistance: Can degrade or deform at high temperatures.

- Lower Mechanical Strength: Compared to other thermoplastics like polyethylene or polypropylene.

- Aging & Degradation: May degrade over time when exposed to UV radiation or harsh conditions.

- Flammability: Not inherently flame-retardant without additives.

- Cost: Can be more expensive than some alternative plastics like PVC.

Applications

| Applications | , , , , |

|---|

Ethylene Vinyl Acetate

| Products | MFI (g/10 min) | Density (g/Cm3) | Process Metod | Applications | Data Sheet | MSDS |

|---|---|---|---|---|---|---|

| Ethylene Vinyl Acetate | Low VA content (≤ 10%): MFI ranges from 0.5 – 10 g/10 min. Medium VA content (10-30%): MFI ranges from 0.5 – 50 g/10 min. High VA content (≥ 30%): MFI can be >100 g/10 min. | Low VA content (~5%): 0.92 – 0.94 g/cm³ (Similar to LDPE) Medium VA content (10-20%): 0.94 – 0.96 g/cm³ High VA content (20-40%): 0.96 – 0.98 g/cm³ | Extrusion Injection Molding Blow Molding Thermoforming | glue sticks, packaging adhesives , Solar panel encapsulation, food packaging, shrink films ,Soundproofing, vibration-damping sheets, Drug delivery systems, tubing Insulation for electrical wires , sports padding |