Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or fomed. General-purpose polystyrene is clear, hard, and brittle. As a thermoplastic polymer, polystyrene is in a solid (glassy) state at room temperature but flows if heated above about 100 °C, its glass transition temperature.and also It has wide applications in various industries including packaging, construction, and automotive.

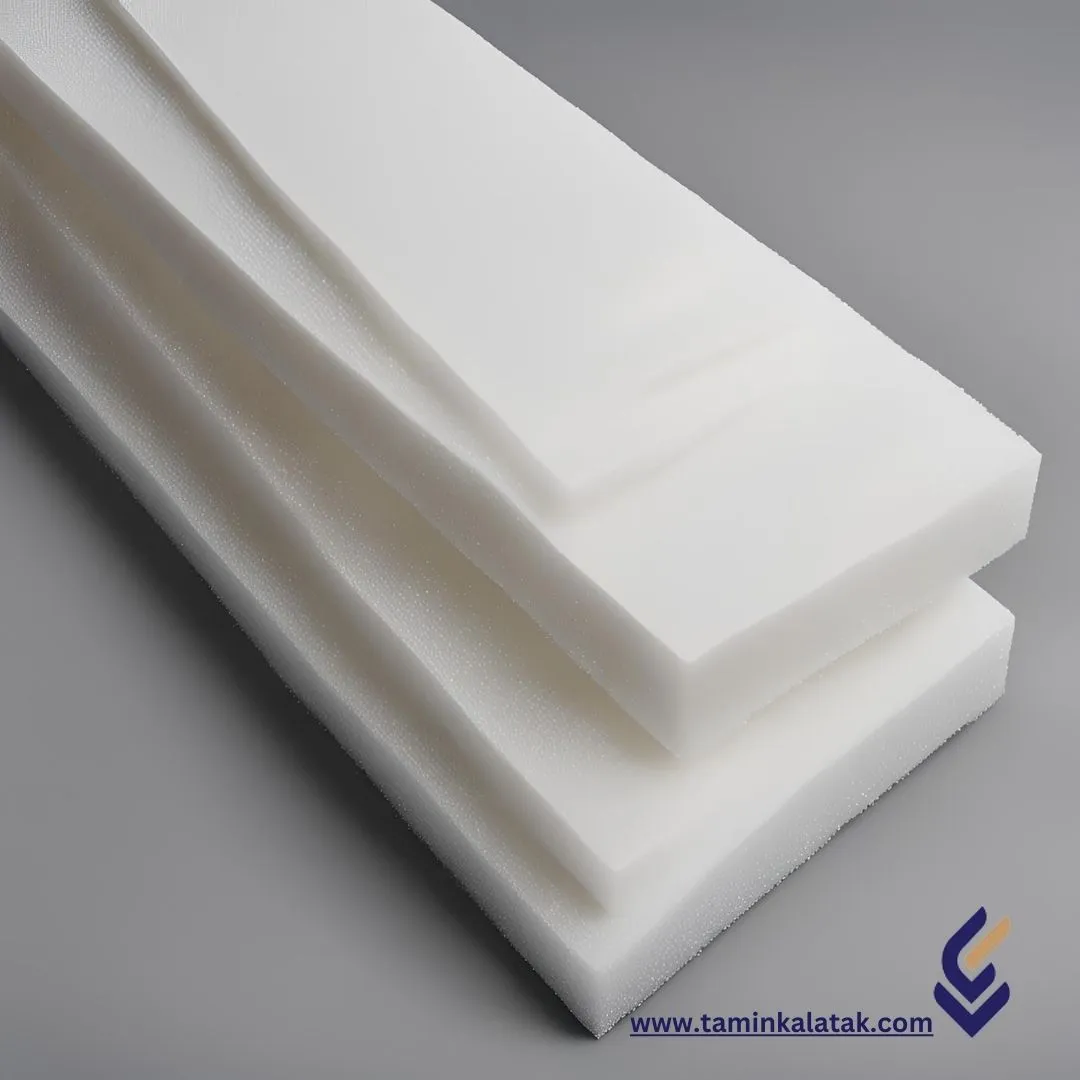

Expandable PolyStyrene (EPS)

Expanded Polystyrene (EPS) is a rigid, closed-cell thermoplastic foam material produced from solid polystyrene beads. This polymer is obtained by polymerizing styrene monomer and contains a blowing agent (typically pentane) dissolved within the polystyrene beads.

Each solid bead of polystyrene contains small amounts of this gas, which expands when exposed to heat (in the form of steam), forming a closed-cell foam structure. These expanded cells can occupy up to 40 times the volume of the original polystyrene beads. Through further heat treatment and molding, large EPS blocks can be shaped into custom forms and components for diverse industrial uses.

Structure of Expanded Polystyrene

The structure of EPS consists of small, closed-cell foam beads made from polystyrene. When heated, these beads expand to as much as 50 times their original size. Each bead contains numerous microscopic air cavities that contribute to its lightweight and insulating properties.

Properties of Expanded Polystyrene (EPS)

EPS serves as a core polymer material in many applications due to its lightweight, moisture resistance, and long service life.

Studies show that softening of EPS begins between 100 °C and 120 °C. During thermal degradation, it melts at approximately 160 °C, vaporizes, and at around 275 °C, releases toxic gases.

EPS is an inert, low-density hydrocarbon thermoplastic, consisting of spherical granules that are approximately 2% polystyrene and 98% air.

Applications of Expanded Polystyrene (EPS)

1. Building and Construction

EPS is widely used in construction because of its excellent thermal insulation and lightweight characteristics. It is used as:

-

Insulation panels for façades, walls, roofs, and floors.

-

Buoyant material in marine structures such as marinas and floating bridges.

-

Lightweight fill in road and railway embankments to reduce soil load.

2. Food Packaging

EPS is commonly used in food packaging for products such as seafood, fruits, and vegetables.

It is also used for food-service containers, including drink cups, food trays, and clamshell boxes.

3. Industrial Packaging

EPS provides complete protection for industrial products during handling and transportation, ensuring safety against shock and mechanical damage.

4. Other Applications

EPS can be molded into virtually any shape — for example:

Sport helmets, child car seats, cushioning pads, structural insulated panels (SIPs), and lightweight automotive seating.

Advantages of EPS

✅ Lightweight

✅ Water-resistant

✅ Easy to manufacture

✅ Energy-efficient

✅ Durable and long-lasting

Disadvantages of EPS

❌ Vulnerable to mechanical compression

❌ Limited fire resistance

❌ Non-biodegradable

EPS Market Price in Türkiye

The price of Expanded Polystyrene (EPS) in Türkiye depends on various factors, including market fluctuations, grade type, manufacturer brand, and supply-demand conditions.

For the latest EPS pricing, you can contact our commercial experts to receive up-to-date market rates and guidance on selecting the most cost-effective material.

Purchasing EPS

To purchase EPS, our technical experts can assist you in selecting the appropriate grade to ensure precise and efficient production tailored to your product requirements.

Common EPS Grades

EPS-200 (Snowa Grade)

Snowa EPS-200 is a versatile grade of lightweight expandable polystyrene with medium-to-coarse bead size and high moldability. It is widely used in packaging, insulation, and lightweight ceiling block production.

This grade contains a controlled amount of pentane blowing agent for optimal pre-expansion and molding performance.

F100 EPS

F100 EPS is a specialized grade designed for producing lightweight, insulated, and moldable products across various industries.

Due to its excellent mechanical properties, thermal performance, and high formability, it is ideal for packaging, construction, and industrial components.

EPS-200 (Tabriz Petrochemical)

EPS-200 from Tabriz Petrochemical is a high-density, durable EPS grade used for insulation and structural components.

It features excellent dimensional stability, precise molding capability, and outstanding thermal resistance, making it suitable for construction, industrial packaging, and technical molding applications.

EPS-300 (Tabriz Petrochemical)

Similar to EPS-200, EPS-300 is produced by Tabriz Petrochemical and offers high density, multi-stage pre-expansion capability, and precise molding characteristics.

It is primarily used in construction, heavy-duty industrial packaging, and structural components.

EPS Manufacturing Process

1. Pre-Expansion

Raw EPS beads are exposed to steam, which vaporizes the blowing agent, expanding the beads several times their original volume.

Precise control of temperature and time determines the final foam density.

2. Stabilization

The expanded beads are stored in ventilated silos to allow internal pressure to equalize, ensuring they are ready for molding.

This step is crucial to achieving uniform, defect-free foam.

3. Molding

Pre-expanded beads are placed in molds and reheated with steam. The beads fuse together, forming a solid part in the desired shape and dimensions — such as blocks, sheets, or custom components.

4. Drying and Cutting

After molding, the final product is dried and, if necessary, cut to the required dimensions.

Key Features of EPS

-

Lightweight and excellent thermal insulation → ideal for building insulation (walls, ceilings, floors).

-

Shock absorption and energy dissipation → suitable for protective packaging of sensitive equipment.

-

Easy and economical processing → enables high-volume production at low cost.

-

Recyclable → reduces environmental impact and promotes sustainability.

Market Outlook and Industry Insights

With the continuous growth of the construction and packaging sectors, global and domestic demand for Expanded Polystyrene (EPS) is steadily increasing.

Companies investing in modern production equipment and precise process control can produce EPS with uniform quality meeting international standards.

Summary

Expanded Polystyrene (EPS) is one of the most important lightweight and insulating polymers used in construction, packaging, and technical applications.

Its low weight, excellent thermal and moisture resistance, and easy processability make it a cost-effective and efficient alternative to traditional insulation materials, helping reduce energy consumption and production costs.

EPS is available in several grades — including F100, EPS-200, and EPS-300 — each optimized for specific uses such as ceiling blocks, industrial packaging foam, and thermal insulation panels.

The choice of grade depends on density, cell size, and blowing-agent content, all of which determine the mechanical performance of the final product.

Economically, EPS pricing in Türkiye is influenced by global styrene prices, exchange rates, and supply levels from domestic petrochemical producers such as Tabriz Petrochemical and Qa’ed Basir Petrochemical.

Selecting a reliable supplier and maintaining real-time pricing awareness are key factors for successful production planning.

Tamin Kala Tech Co., leveraging an extensive domestic and international supply network, provides specialized EPS grades for diverse industries.

Our technical support team offers expert consultation on grade selection, processing conditions, and production optimization to help improve your product quality and operational efficiency.

Applications

| Applications | , , , |

|---|

EPS

| prodact | Grade | K - value | Bead Size (mm) | Pentanecontentwt% | Process metod | Expanded density | Application / Description | Data Sheet | MSDS | Brochure |

|---|---|---|---|---|---|---|---|---|---|---|

| EPS | HS 121 | 55 | 1.8 - 2.5 | 52,00 | 1.pre-expansion 2.aging 3.molding | 13-15 kg/m³ | Low density block | |||

| EPS | HS 221 | 55 | 1 - 1.8 | 52,00 | 1.pre-expansion 2.aging 3.molding | 14-30 kg/m³ | Medium density block | |||

| EPS | HS 321 | 55 | 0.7 - 1 | 52,00 | 1.pre-expansion 2.aging 3.molding | 18-30 kg/m³ | High density block | |||

| EPS | FC 422 | 55 | 0.5 - 0.7 | 52,00 | 1.pre-expansion 2.aging 3.molding | 20-30 kg/m³ | High density block, shaped packing | |||

| EPS | FC 522 | 55 | 0.3 - 0.5 | 52,00 | 1.pre-expansion 2.aging 3.molding | 22-30 kg/m³ | High density block, shaped packing | |||

| EPS | WP 526 | 55 | 0.3 - 0.5 | 52,00 | 1.pre-expansion 2.aging 3.molding | 22-30 kg/m³ | Thin wall waterproof, shaped molding |