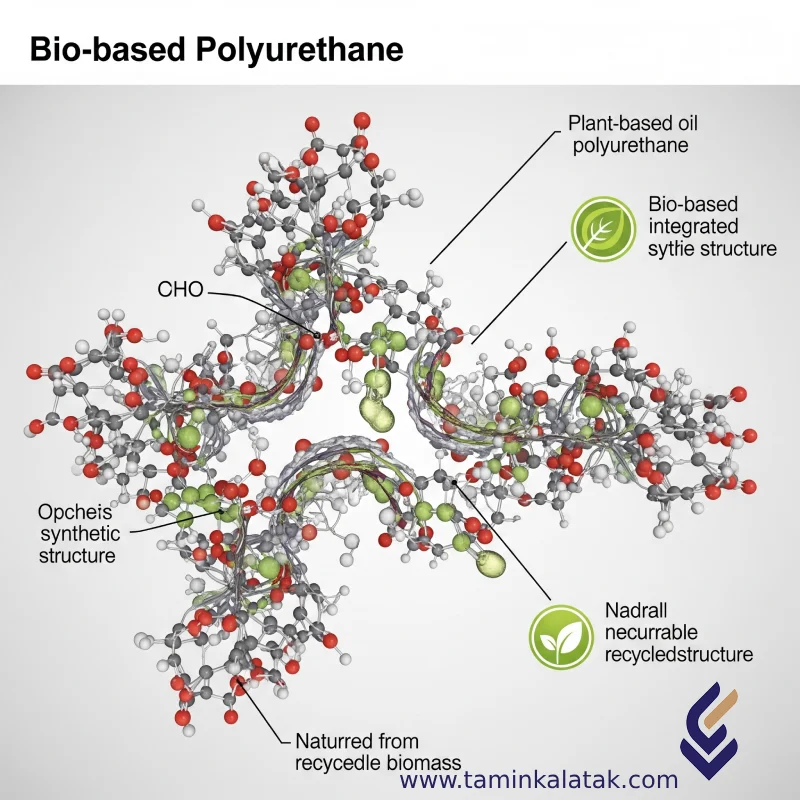

Bio-based polyurethane (BIO-PU) is a flexible and durable polymer produced from renewable resources such as vegetable oils (soybean, castor, palm, etc.). Unlike conventional polyurethanes derived from petrochemical sources, BIO-PU has been developed to reduce dependence on fossil fuels and improve environmental sustainability. Due to its diverse physical and chemical properties, this polymer is widely used in various industries, including automotive, furniture, textiles, and medical applications.

Structure

Bio-based polyurethane is synthesized through the reaction between bio-based polyols and isocyanates. Bio-polyols are directly derived from natural sources such as vegetable oils. In BIO-PU, depending on the type of raw materials used, physical properties such as hardness, tensile strength, or flexibility can be adjusted. Its structure is designed to achieve performance comparable to or even better than that of traditional polyurethanes.

Properties

-

Biodegradable (in certain grades)

-

Lightweight and abrasion-resistant

-

Adjustable hardness and flexibility

-

Good chemical resistance

-

Stable thermal performance

-

Partial recyclability in specific grades

Applications

-

Furniture industry: Flexible foams for seats and cushions

-

Automotive: Interior components, sound and thermal insulation

-

Medical field: Temporary implant materials, elastic bandages, and disposable equipment

-

Flooring and industrial coatings: Due to high wear resistance

-

Footwear and apparel: Shoe soles and impact-resistant inner layers

-

Electronics: Flexible protectors and insulators

Advantages

-

Reduces dependence on petroleum-based resources

-

Environmentally friendly

-

Tunable and precisely engineered properties

-

Comparable or superior performance to conventional polyurethane

-

Suitable for sensitive applications such as medical use

Disadvantages

-

Higher production costs compared to traditional polymers

-

Greater sensitivity to moisture in certain grades

-

Requires specific production and storage conditions

-

Complete biodegradability may not always be achieved

-

Limited and inconsistent supply of bio-based raw materials on an industrial scale