Polymer

Polymers are made up of very large molecules made up of many repeating units called monomers, which ultimately form this long polymer chain

Auxiliaries & Additives

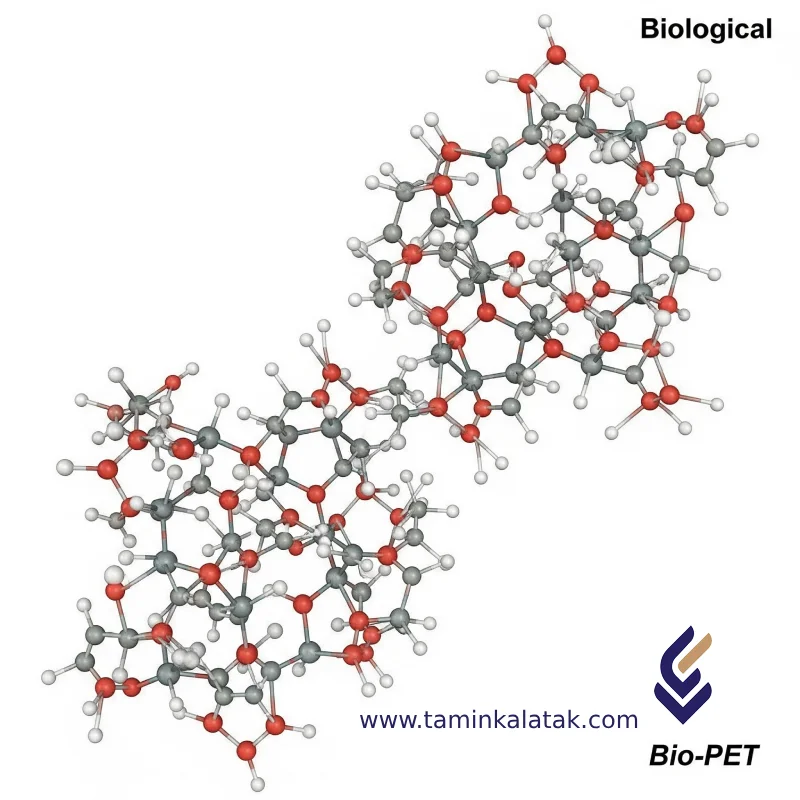

Biobased PolyEthylene Terephthalate (Bio-PET)

Bio-based Polyethylene Terephthalate (Bio-PET) is a type of thermoplastic polymer produced from renewable resources such as sugarcane molasses or corn starch. The chemical structure of Bio-PET is very similar to traditional PET, with the difference being that in Bio-PET, some or all of its ethylene glycol component is derived from biological sources. This material features a linear chain structure with repeating ethylene terephthalate units, which results in outstanding mechanical and thermal properties.

Features of Bio-based Polyethylene Terephthalate

- High thermal resistance

- Good optical clarity

- Desirable tensile strength and impact resistance

- Recyclable within the existing PET system

- Chemical resistance to oils, fats, and weak solvents

- Dimensional stability over time

Applications of Bio-based Polyethylene Terephthalate

- Food Packaging: Water bottles, carbonated beverage bottles, food containers

- Pharmaceutical and Personal Care Packaging

- Synthetic Fibers: For apparel, carpets, and industrial textiles

- Lightweight Engineering Applications: Such as automotive and electronic components

- Production of Transparent Packaging Films: With high printability

Disadvantages of Bio-based Polyethylene Terephthalate

- Higher production cost compared to traditional PET

- Dependency on agricultural resources for raw material supply

- Not widely available in some markets

- Low biodegradability in the natural environment (similar to conventional PET)

- Requires property enhancements for certain specialized industrial applications

Advantages of Bio-based Polyethylene Terephthalate

- Produced from renewable resources (reducing dependency on fossil fuels)

- Reduced greenhouse gas emissions during the production process

- Compatible with traditional PET recycling processes

- Suitable for food contact (approved by the FDA and EFSA)

- Improves brand image for environmentally conscious companies

Applications

(Bio-PET)

| Products | Grid | Melt Flow Index (MFI) (g/10min) | Density (g/cm³) | Process method | Applications |

|---|---|---|---|---|---|

| Bio-PET for beverage bottles | Bio-PET 30 | 65,00 | 138,00 | Blow molding | Bottled water, soda, carbonated drinks |

| Bio-PET for food packaging | Bio-PET F85 | 1,00 | 137,00 | Thermoforming | Food packaging containers, trays, lids |

| Bio-PET for textile fibers | Bio-PET T100 | 25,00 | 136,00 | (Melt Spinning) | Fibers for clothing, carpets, industrial textiles |

| Reinforced Industrial Bio-PET | Bio-PET G90 | 12,00 | 139,00 | Injection molding | Auto parts, home appliances, electronic enclosures |

| Bio-PET film with high transparency | Bio-PET F30 | 12,00 | 138,00 | Film extrusion | Packaging film, high printability, lamination |