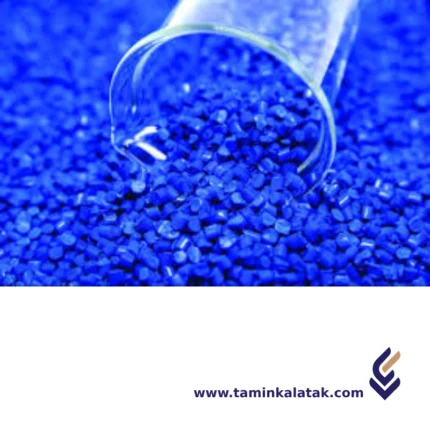

Carbonate Masterbatch

Carbonate Masterbatch is a type of filler masterbatch that consists of calcium carbonate (CaCO₃) dispersed in a polymer carrier resin, such as polyethylene (PE) or polypropylene (PP). It is widely used in the plastic industry to improve the mechanical properties of plastic products, reduce production costs, and enhance processability.

Structure

The structure of carbonate masterbatch consists of finely ground calcium carbonate (CaCO₃) particles dispersed in a polymer carrier resin, such as polyethylene (PE), polypropylene (PP), or other thermoplastics. The calcium carbonate acts as a functional filler, providing improved mechanical properties, cost reduction, and enhanced processability. To ensure uniform dispersion and compatibility with the base polymer, the CaCO₃ particles are often coated with surface modifiers or coupling agents, such as stearic acid, which enhances their bonding with the polymer matrix. The polymer carrier resin serves as a medium to evenly distribute the calcium carbonate during processing, preventing agglomeration and ensuring consistent performance in the final product. The proportion of CaCO₃ in the masterbatch can vary depending on the intended application, typically ranging from 20% to 80%. This structure allows for improved stiffness, thermal stability, and opacity while maintaining the flexibility and processability of the plastic.Properties

Carbonate masterbatch possesses several key properties that make it a valuable additive in plastic production. It has high dispersion, ensuring uniform distribution of calcium carbonate within the polymer matrix, which enhances the mechanical properties of the final product. The masterbatch improves stiffness, rigidity, and impact strength while maintaining sufficient flexibility for various applications. It also enhances thermal stability, allowing plastic materials to withstand higher processing temperatures without degradation. Due to the presence of calcium carbonate, it increases opacity and whiteness, which is particularly beneficial for films, sheets, and molded products. The masterbatch helps in cost reduction by replacing a portion of expensive polymer resin with a more affordable filler without compromising product quality. Additionally, it improves processability by enhancing extrusion and molding performance, reducing shrinkage, and providing better dimensional stability. Its density varies depending on the calcium carbonate concentration, typically ranging from 1.5 to 2.2 g/cm³, and it has a melt flow index (MFI) tailored to match the base polymer for seamless integration into manufacturing processes.Applications

- Used in plastic films such as shopping bags, garbage bags, and agricultural films to enhance opacity and reduce costs.

- Applied in injection molding for household products, containers, and automotive components to improve strength and stiffness.

- Utilized in blow molding for producing bottles and hollow plastic items with better rigidity.

- Incorporated in extruded sheets, pipes, and profiles to enhance mechanical properties and processing efficiency.

- Used in non-woven fabrics to improve stiffness and provide a better hand feel for hygiene products.

- Applied in thermoforming to manufacture rigid packaging trays and disposable containers.

Advantages

- Reduces production costs by replacing expensive polymer resins with calcium carbonate.

- Improves mechanical properties, such as stiffness, impact resistance, and dimensional stability.

- Enhances processability by improving extrusion, injection, and blow molding performance.

- Increases opacity and whiteness, reducing the need for additional whitening agents.

- Provides thermal stability, allowing for high-temperature processing without degradation.

- Reduces shrinkage and warping, leading to better-finished products.

- Eco-friendly as it reduces polymer consumption and can improve recyclability in some applications.

Disadvantages

- Higher filler content may reduce flexibility, making some plastic products more brittle.

- May affect transparency, making it unsuitable for clear plastic applications.

- Can alter surface properties, potentially impacting printability or adhesion in certain cases.

- May require surface treatment for better compatibility with some polymer matrices.

- Increased density can add weight to the final product, which may be undesirable in lightweight applications.

Masterbatch Anti algae and moss

An anti-algae and moss masterbatch is a specialized additive used in plastic products to prevent the growth of algae, moss, fungi, and other microorganisms. It is commonly used in applications where plastics are exposed to moisture, humidity, and outdoor conditions.

StructureThe structure of an anti-algae and moss masterbatch consists of a polymer carrier, biocidal agents, UV stabilizers, and dispersing aids. The polymer carrier, typically made of polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC), ensures compatibility with the final plastic product and allows for easy incorporation during manufacturing. Biocidal agents are the active components that prevent the growth of algae, moss, and fungi by disrupting their cellular processes or inhibiting their ability to thrive on the plastic surface. UV stabilizers are often included to protect the plastic from ultraviolet radiation, which can accelerate degradation and create conditions favorable for microbial growth. Dispersing aids help evenly distribute the active ingredients throughout the plastic matrix, ensuring consistent protection over time. This carefully formulated combination helps extend the lifespan of plastic products exposed to moisture and outdoor environments while maintaining their aesthetic and functional properties.

PropertiesAnti-algae and moss masterbatch exhibits several key properties that enhance the durability and performance of plastic products in outdoor and high-moisture environments. It possesses strong antimicrobial and biocidal activity, effectively preventing the growth of algae, moss, fungi, and other microorganisms on plastic surfaces. The masterbatch is highly weather-resistant, with the ability to withstand prolonged exposure to sunlight, humidity, and rain without losing its effectiveness. It is often formulated with UV stabilizers to prevent degradation caused by ultraviolet radiation, ensuring long-term protection and maintaining the integrity of the plastic. The dispersion of active agents within the polymer matrix is uniform, allowing consistent performance across the entire product. It is also chemically stable, meaning it does not easily leach out or degrade under normal usage conditions. Additionally, it is compatible with various thermoplastic materials, such as polyethylene, polypropylene, and PVC, making it suitable for a wide range of applications, including roofing materials, outdoor furniture, agricultural films, and drainage systems.

Applications

-

- Agriculture: Used in greenhouse films, mulch films, and irrigation pipes to prevent algae growth.

- Construction: Applied in roofing sheets, tiles, drainage pipes, and water tanks to inhibit moss formation.

- Marine Industry: Helps reduce biofouling on boats, docks, and marine equipment.

- Textile Industry: Used in synthetic outdoor fabrics and geotextiles to prevent microbial degradation.

- Packaging Industry: Applied in food packaging, beverage containers, and water storage units to minimize contamination.

Advantages

-

- Prevents algae and moss growth, extending product lifespan.

- Reduces maintenance and cleaning costs.

- Enhances aesthetic appeal by preventing discoloration and surface damage.

- Improves material durability by protecting against microbial degradation.

- Available in eco-friendly formulations.

- Compatible with various plastic polymers like PE, PP, and PVC.

Disadvantages

-

- Increases production costs due to specialized additives.

- Some formulations may have environmental impacts, especially in aquatic ecosystems.

- Effectiveness may decrease over time as active ingredients degrade.

- Subject to regulatory restrictions depending on the biocides used.

- May affect the recyclability of plastic materials.

Masterbatch Anti fungus and mold

A masterbatch for anti-fungus and anti-mold applications is a concentrated additive used in plastic manufacturing to prevent fungal and mold growth. It is commonly used in polymer processing for products exposed to humid or damp environments, such as packaging, construction materials, agricultural films, and household items.

StructureA Masterbatch anti-fungus and mold formulation typically consists of a polymer carrier, such as polyethylene or polypropylene, which acts as a base resin to evenly distribute the additives throughout the material. The key components are the active anti-fungal and anti-mold agents, which include biocides, fungicides, and anti-microbial agents that inhibit the growth of fungi, mold, and bacteria. These can include chemicals like zinc pyrithione, silver-based compounds, or organosulfur agents. To enhance the processing and performance, fillers such as calcium carbonate or silica may be added, along with stabilizers like UV stabilizers, antioxidants, or light stabilizers to maintain the longevity of the masterbatch. Additionally, processing aids such as lubricants and dispersing agents are often incorporated to improve the flow and dispersion of the ingredients during manufacturing. In some cases, surfactants or pigments might be included to optimize the dispersion and give the product color, though this is less common for anti-fungal and mold masterbatches. These masterbatches are then mixed into the final product, such as plastics or coatings, to provide effective protection against mold and fungal growth.

PropertiesMasterbatch anti-fungus and mold possesses several key properties that make it effective in preventing microbial growth in plastic and polymer-based materials. It provides strong antifungal and antimicrobial protection by inhibiting the growth of mold, mildew, and bacteria, ensuring long-term durability and hygiene of the final product. The formulation is designed for excellent dispersion within the base polymer, allowing uniform distribution of active agents. It is highly stable under various environmental conditions, including high temperatures and UV exposure, preventing degradation over time. Many formulations are non-toxic and comply with regulatory safety standards, making them suitable for applications in packaging, medical devices, and consumer goods. Additionally, these masterbatches maintain the mechanical properties of the base polymer, ensuring that strength, flexibility, and appearance remain unaffected. They are also compatible with a wide range of polymers such as polyethylene, polypropylene, and polystyrene, offering versatility in application. Some variations include moisture-resistant and weatherproof properties, making them ideal for both indoor and outdoor use.

Applications

- Used in plastic packaging to prevent mold growth on food and consumer goods

- Incorporated into medical devices and equipment to ensure hygiene and reduce microbial contamination

- Applied in household products such as plastic containers, furniture, and flooring to prevent fungal damage

- Used in automotive interiors to prevent mold buildup in humid conditions

- Integrated into construction materials like PVC pipes, wall panels, and insulation for long-term mold resistance

- Employed in textiles and synthetic fibers to enhance durability and cleanliness

- Added to coatings and paints to protect surfaces from fungal and bacterial growth

- Utilized in agricultural films and greenhouse materials to minimize mold-related crop damage

Advantages

- Provides long-lasting antifungal and antimicrobial protection

- Helps in extending the lifespan of plastic materials by preventing microbial degradation

- Reduces health risks associated with mold exposure, particularly in medical and food-related applications

- Compatible with a wide range of polymers and processing methods

- Maintains the mechanical and aesthetic properties of the base material

- Some formulations are non-toxic and environmentally friendly

- Enhances hygiene and safety in various industries, including food, healthcare, and construction

Disadvantages

- May increase production costs due to the addition of specialized additives

- Some formulations may have regulatory restrictions for food contact or medical use

- Prolonged exposure to high temperatures and UV radiation can cause reduced effectiveness over time

- The presence of antimicrobial agents may lead to resistance development in microorganisms

- Requires precise formulation and dosage to avoid affecting the physical properties of the final product