Anti-UV Masterbatch

Anti-UV Masterbatch is a specialized additive used in plastic manufacturing to enhance the UV resistance of polymer-based products. It consists of ultraviolet (UV) stabilizers and absorbers dispersed in a carrier resin, making it easier to incorporate into plastic during processing.

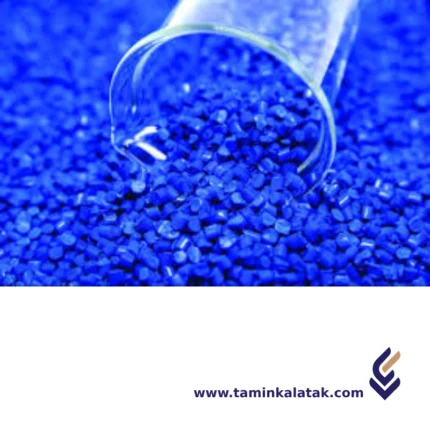

StructureThe structure of an anti-UV masterbatch consists of a combination of UV stabilizers, a carrier resin, and sometimes additional additives to enhance performance. The UV stabilizers, which can include UV absorbers and hindered amine light stabilizers (HALS), are the active components that protect plastics from degradation by absorbing or neutralizing harmful ultraviolet radiation. These stabilizers are uniformly dispersed within a carrier resin, which is typically the same or compatible with the final polymer to ensure easy blending during processing. The carrier resin acts as a medium that holds and delivers the UV stabilizers into the plastic matrix. Depending on the application, other additives such as antioxidants, processing aids, or heat stabilizers may be included to improve the overall durability of the final product. The masterbatch is typically produced in pellet or granular form, allowing for uniform distribution when mixed with base polymers during the manufacturing process.

PropertiesAnti-UV masterbatch possesses several key properties that enhance the durability and performance of plastic products exposed to sunlight. It effectively absorbs and dissipates ultraviolet radiation, preventing polymer degradation, discoloration, and brittleness. The masterbatch is designed to be thermally stable, ensuring that it can withstand high processing temperatures without losing its effectiveness. It is highly compatible with various polymers, including polyethylene, polypropylene, PVC, and ABS, allowing for easy incorporation into different plastic formulations. The dispersion quality is crucial, ensuring uniform distribution of UV stabilizers within the polymer matrix to achieve consistent protection. Additionally, anti-UV masterbatch can be tailored to specific applications by combining different types of UV stabilizers, such as UV absorbers and hindered amine light stabilizers (HALS), for comprehensive protection. It also maintains the mechanical properties of plastics over time, reducing surface cracking and extending the lifespan of products used in outdoor or high-exposure environments.

Applications

- Agricultural films, such as greenhouse covers and mulch films, to protect crops from UV damage.

- Outdoor furniture and construction materials, including pipes, sheets, and roofing, to prevent weathering and brittleness.

- Automotive plastic parts, such as dashboards and exterior trims, to resist sun-induced fading and cracking.

- Packaging materials, especially for products sensitive to UV exposure, such as food and pharmaceuticals.

- Electrical and electronic components, ensuring longer durability for plastic casings exposed to sunlight.

- Textile fibers and synthetic fabrics, improving UV resistance in outdoor clothing and industrial fabrics.

Advantages

- Protects plastics from UV-induced degradation, extending product lifespan.

- Reduces discoloration, brittleness, and surface cracking in exposed plastic materials.

- Enhances thermal stability, making it suitable for high-temperature processing.

- Compatible with various polymers, allowing flexibility in application.

- Cost-effective solution compared to using inherently UV-resistant polymers.

Disadvantages

- May slightly alter the color or transparency of clear plastic products.

- Effectiveness depends on the concentration and type of stabilizer used.

- Higher costs compared to non-UV-stabilized plastic formulations.

- Prolonged exposure to extreme UV conditions may still lead to gradual degradation over time.

Masterbatch Anti algae and moss

An anti-algae and moss masterbatch is a specialized additive used in plastic products to prevent the growth of algae, moss, fungi, and other microorganisms. It is commonly used in applications where plastics are exposed to moisture, humidity, and outdoor conditions.

StructureThe structure of an anti-algae and moss masterbatch consists of a polymer carrier, biocidal agents, UV stabilizers, and dispersing aids. The polymer carrier, typically made of polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC), ensures compatibility with the final plastic product and allows for easy incorporation during manufacturing. Biocidal agents are the active components that prevent the growth of algae, moss, and fungi by disrupting their cellular processes or inhibiting their ability to thrive on the plastic surface. UV stabilizers are often included to protect the plastic from ultraviolet radiation, which can accelerate degradation and create conditions favorable for microbial growth. Dispersing aids help evenly distribute the active ingredients throughout the plastic matrix, ensuring consistent protection over time. This carefully formulated combination helps extend the lifespan of plastic products exposed to moisture and outdoor environments while maintaining their aesthetic and functional properties.

PropertiesAnti-algae and moss masterbatch exhibits several key properties that enhance the durability and performance of plastic products in outdoor and high-moisture environments. It possesses strong antimicrobial and biocidal activity, effectively preventing the growth of algae, moss, fungi, and other microorganisms on plastic surfaces. The masterbatch is highly weather-resistant, with the ability to withstand prolonged exposure to sunlight, humidity, and rain without losing its effectiveness. It is often formulated with UV stabilizers to prevent degradation caused by ultraviolet radiation, ensuring long-term protection and maintaining the integrity of the plastic. The dispersion of active agents within the polymer matrix is uniform, allowing consistent performance across the entire product. It is also chemically stable, meaning it does not easily leach out or degrade under normal usage conditions. Additionally, it is compatible with various thermoplastic materials, such as polyethylene, polypropylene, and PVC, making it suitable for a wide range of applications, including roofing materials, outdoor furniture, agricultural films, and drainage systems.

Applications

-

- Agriculture: Used in greenhouse films, mulch films, and irrigation pipes to prevent algae growth.

- Construction: Applied in roofing sheets, tiles, drainage pipes, and water tanks to inhibit moss formation.

- Marine Industry: Helps reduce biofouling on boats, docks, and marine equipment.

- Textile Industry: Used in synthetic outdoor fabrics and geotextiles to prevent microbial degradation.

- Packaging Industry: Applied in food packaging, beverage containers, and water storage units to minimize contamination.

Advantages

-

- Prevents algae and moss growth, extending product lifespan.

- Reduces maintenance and cleaning costs.

- Enhances aesthetic appeal by preventing discoloration and surface damage.

- Improves material durability by protecting against microbial degradation.

- Available in eco-friendly formulations.

- Compatible with various plastic polymers like PE, PP, and PVC.

Disadvantages

-

- Increases production costs due to specialized additives.

- Some formulations may have environmental impacts, especially in aquatic ecosystems.

- Effectiveness may decrease over time as active ingredients degrade.

- Subject to regulatory restrictions depending on the biocides used.

- May affect the recyclability of plastic materials.