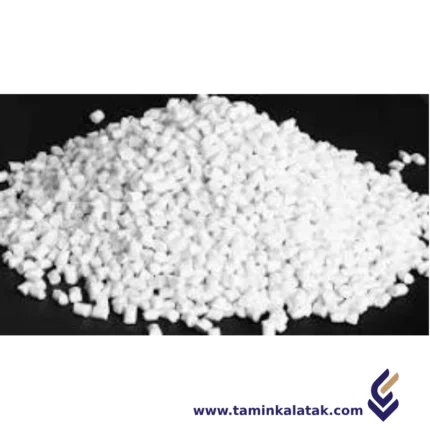

Antiblock Masterbatch

Antiblock masterbatch is an additive used in plastic films and sheets to reduce surface adhesion and prevent blocking, where plastic layers stick together after processing. It contains fine inorganic particles such as silica, talc, or calcium carbonate, dispersed in a polymer carrier like PE (polyethylene) or PP (polypropylene).

Structure

The structure of antiblock masterbatch consists of a polymer carrier resin, typically polyethylene (PE) or polypropylene (PP), combined with finely dispersed inorganic antiblocking agents such as silica, talc, or calcium carbonate. These inorganic particles create a micro-rough surface on the plastic film, reducing contact area and minimizing adhesion between layers. The masterbatch is formulated to ensure uniform dispersion of the antiblocking agents, preventing film sticking while maintaining optical properties such as transparency and gloss. In addition to antiblocking agents, the formulation may include processing aids and slip additives to enhance film handling and extrusion performance. The overall composition is designed to provide effective antiblocking performance without compromising the mechanical and optical qualities of the final product.Properties

Antiblock masterbatch has several important properties that enhance the performance of plastic films and sheets. It effectively reduces blocking by introducing micro-roughness on the surface, preventing plastic layers from sticking together. The masterbatch is designed to maintain good optical properties, ensuring minimal impact on transparency and haze, which is especially important for clear films. It also improves the handling and processing of films by reducing friction, often working in combination with slip agents to enhance surface smoothness. The thermal and chemical stability of antiblock masterbatch ensures that it remains effective under high processing temperatures and various environmental conditions. Additionally, it enhances the efficiency of film unwinding, bag opening, and packaging applications without negatively affecting the mechanical strength of the polymer.Applications of Antiblock Masterbatch

- Blown Films – Used in LDPE, LLDPE, and HDPE films to prevent blocking.

- Cast Films – Applied in BOPP and CPP films for packaging and lamination.

- Agricultural Films – Helps prevent sticking in greenhouse and mulch films.

- Shrink and Stretch Wraps – Ensures smooth unwinding and handling.

- Thermoformed Sheets – Reduces adhesion in plastic trays and disposable containers.

- Flexible Packaging – Improves the usability of food and industrial packaging films.

Advantages of Antiblock Masterbatch

- Prevents Film Blocking – Reduces adhesion between plastic layers for easy handling.

- Maintains Transparency – Optimized formulations ensure minimal haze.

- Improves Processing Efficiency – Enhances film unwinding and bag separation.

- Compatible with Various Polymers – Works well with PE, PP, and other film resins.

- Enhances Surface Properties – Reduces friction when combined with slip agents.

- Cost-Effective – Reduces defects and improves production efficiency.

Disadvantages of Antiblock Masterbatch

- Potential Reduction in Clarity – High concentrations may slightly increase haze.

- Can Affect Surface Smoothness – Roughness introduced by antiblock agents may impact certain applications.

- Limited Performance in Thick Films – More effective in thin films than in rigid or thick sheets.

- Possible Interaction with Other Additives – Requires careful formulation to avoid negative effects on slip or anti-static properties.