Maleic Anhydride Grafted PE

Maleic Anhydride Grafted Polyethylene (MAH-g-PE) is a type of functionalized polyethylene where maleic anhydride (MAH) is grafted onto the polyethylene (PE) backbone. This modification enhances the compatibility of polyethylene with polar materials such as metals, glass, and polar polymers (e.g., polyamides, polyesters, and EVOH)

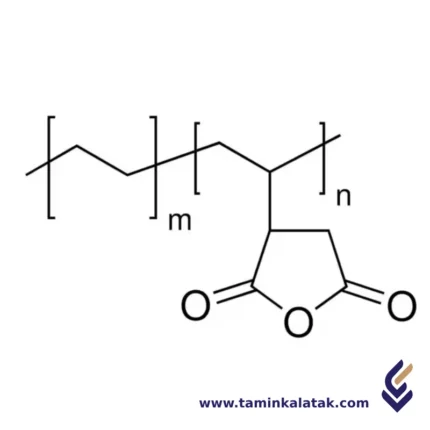

Structure Maleic Anhydride Grafted PE

The structure of maleic anhydride grafted polyethylene (MAH-g-PE) consists of a polyethylene (PE) backbone with randomly grafted maleic anhydride (MAH) functional groups along the chain. The polyethylene backbone provides flexibility, hydrophobicity, and mechanical strength, while the maleic anhydride groups introduce polar functionality, improving adhesion and compatibility with polar materials. The grafting process typically occurs through a free radical mechanism, where maleic anhydride is chemically bonded to the polyethylene backbone using an initiator, such as peroxide. The resulting structure maintains the overall properties of polyethylene but gains reactive anhydride groups that can interact with hydroxyl, amine, or other polar functional groups, making it valuable for applications like compatibilization, adhesion promotion, and composite reinforcement.Properties Maleic Anhydride Grafted PE

Maleic anhydride grafted polyethylene (MAH-g-PE) exhibits a combination of properties derived from both polyethylene and maleic anhydride functional groups. It retains the flexibility, toughness, and chemical resistance of polyethylene while gaining enhanced adhesion, compatibility, and reactivity due to the grafted maleic anhydride. The presence of polar anhydride groups improves its ability to bond with polar materials such as metals, glass, polyamides, and other polar polymers, making it an effective compatibilizer in polymer blends and composites. MAH-g-PE also enhances the dispersion of fillers such as glass fibers and wood fibers in polyethylene matrices, leading to improved mechanical properties in composite materials. Additionally, it provides better wettability and surface modification capabilities, which are beneficial for applications in adhesives, coatings, and multilayer packaging. The degree of grafting and molecular weight of the polyethylene base influence the final properties, including melt flow behavior, adhesion strength, and overall performance in specific applications.Applications Maleic Anhydride Grafted PE

- Adhesive layers in multilayer films – Used in food packaging to bond polyethylene with polar materials like EVOH and polyamides.

- Compatibilizer in polymer blends – Enhances compatibility between polyethylene and polar polymers such as polyamide (PA) and polyester (PET).

- Coupling agent in composites – Improves adhesion between polyethylene and fillers like glass fibers, wood fibers, and nanomaterials.

- Surface modification – Used in coatings and primers to enhance adhesion to metals, glass, and other substrates.

- Pipe and cable coatings – Improves adhesion and durability in protective layers for pipes and electrical cables.

Advantages Maleic Anhydride Grafted PE

- Enhances adhesion to polar materials, improving compatibility in multilayer structures.

- Improves dispersion of fillers and reinforcements, leading to stronger and more durable composites.

- Retains the flexibility, toughness, and chemical resistance of polyethylene.

- Provides better surface wettability for coatings and adhesives.

- Maintains processability and can be used with standard polyethylene processing techniques.

Disadvantages Maleic Anhydride Grafted PE

- Grafting efficiency can vary, affecting performance consistency.

- May reduce the mechanical strength of the polyethylene matrix if over-grafted.

- Can introduce slight hydrophilicity, which may not be desirable in all applications.

- Higher cost compared to regular polyethylene due to additional processing and functionalization steps.

- Limited thermal stability at very high temperatures due to the presence of maleic anhydride groups.