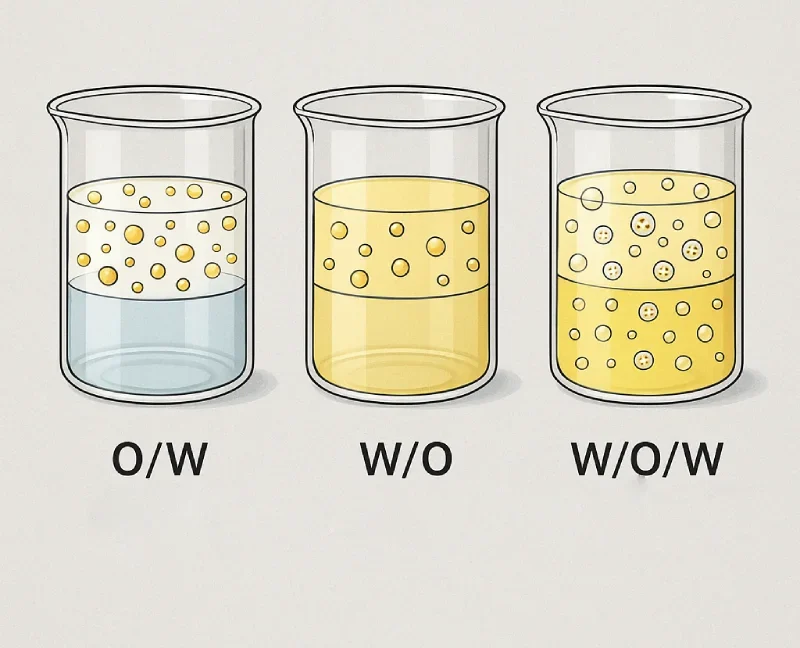

Types of emulsions

Emulsion refers to the dispersion of one liquid (the internal phase) as fine droplets within another liquid (the continuous phase), without complete dissolution in the host phase. Emulsions play a key role in polymer, paint, cosmetic, food, pharmaceutical, and petroleum industries. Choosing the right type of emulsion and a suitable emulsifier—both technically and economically—can significantly affect the final product quality and production cost.

Structure and Chemical Nature of Emulsions

An emulsion is a multiphase physical system, whose chemical structure depends on the composition of its phases and the role of emulsifiers:

-

Internal phase (dispersed phase): can be oil/lipid or water.

-

Continuous phase: the medium in which the droplets are suspended (water or oil).

-

Emulsifiers: amphiphilic molecules with a hydrophilic head and a lipophilic tail that reduce interfacial tension and prevent droplet coalescence by forming a protective film.

-

Secondary stabilizers: polymers, resins, or solid particles (Pickering stabilizers) that enhance mechanical stability and viscosity.

From a chemical standpoint, emulsifier selection is based on the Hydrophilic–Lipophilic Balance (HLB) value:

-

Emulsifiers with high HLB (8–18) are suited for oil-in-water (O/W) emulsions.

-

Emulsifiers with low HLB (3–8) are suited for water-in-oil (W/O) emulsions.

Physical and Chemical Properties of Emulsions

-

Droplet size: ranges from nanometers (nanoemulsions) to micrometers; influences optical, stability, and mechanical properties.

-

Viscosity: depends on internal phase concentration, emulsifier type, and working temperature.

-

Stability: resistance to syneresis, coalescence, phase separation, pH, and temperature changes.

-

Thermal behavior: some emulsions break down or separate at elevated temperatures.

-

Chemical sensitivity: reactions with acids, bases, or oxidants can reduce stability.

Comparative Table of Emulsion Types

| Type of Emulsion | Internal Phase | Continuous Phase | Typical HLB | Key Feature | Common Applications |

|---|---|---|---|---|---|

| Oil-in-Water (O/W) | Oil | Water | 8–18 (more hydrophilic) | Washable, light texture | Latex paints, lotions, food emulsions |

| Water-in-Oil (W/O) | Water | Oil | 3–8 (more lipophilic) | Water-resistant, rich feel | Medicinal creams, lubricants |

| Nanoemulsion | Very fine oil/water | Water or oil | Variable | Transparent, highly stable, enhanced absorption | Drug carriers, advanced cleaners |

| Polymer Emulsion | Monomer/polymer dispersed | Water | Specialized emulsifiers | Resin and copolymer production | Emulsion PVC, acrylic emulsions |

| Pickering Emulsion | Oil/water | Water or oil | Solid particles | High physical stability, surfactant-free | Specialty foods, durable coatings |

Applications of Emulsions

1. Paints and Coatings Industry

-

Latex (water-based) paints: acrylic/styrene emulsions for architectural and industrial coatings.

-

Advantages: uniform film formation, low VOC, good washability.

-

Technical Note: choosing the right emulsifier and co-solvent prevents cracking and improves film formation.

2. Cosmetics and Personal Care

-

Lotions, creams, sunscreens: typically O/W for a non-greasy feel, or W/O for long-lasting moisturization.

-

Key Considerations: compatibility with active ingredients (vitamins, UV filters) and control of droplet size for optimal skin absorption.

3. Food Industry

-

Mayonnaise, non-dairy creams, flavor carriers: droplet size and emulsifier type control stability, texture, and mouthfeel.

-

Safety Standards: only food-grade emulsifiers (e.g., lecithin, mono-/diglycerides) are permitted.

4. Pharmaceutical and Electronics Industries

-

Drug delivery systems: nanoemulsions for injectable formulations and liposomal carriers ensure controlled release and high bioavailability.

-

Semiconductor industry: specialized emulsions are used in lithography and chemical processing.

5. Polymer Industry

-

Emulsion PVC and resin systems: used in plastisols, adhesives, and coatings.

-

Key Property: controlled K-value and uniform particle size distribution for optimal mechanical performance.

Advantages and Disadvantages of Emulsions

Advantages:

-

Enable water-based formulations with reduced VOC emissions.

-

Allow control over texture and end-product properties (flexibility, adhesion).

-

Facilitate the transport of insoluble components (e.g., oils, active ingredients).

Disadvantages:

-

Require stabilizing additives, increasing formulation cost.

-

Sensitive to process energy (mixing speed, ultrasonic intensity).

-

Risk of phase separation under improper storage or temperature conditions.

Emulsifiers and Selection Criteria

-

Nonionic surfactants: ideal for thermal stability and broad compatibility (e.g., polyethylene glycol esters).

-

Anionic/Cationic surfactants: used in specific formulations requiring charge interactions.

-

Polymers and resins: enhance viscosity and prevent phase migration.

-

Solid particles: used when surfactant-free formulations are desired.

Selection criteria: HLB value, chemical compatibility, influence on final product properties, cost, and regulatory (safety/food) compliance.

Processing Notes for Emulsion Production

-

Pre-emulsion stage: gradual addition of internal phase with mild stirring.

-

Emulsification equipment: mechanical stirrers, high-shear mixers, high-pressure homogenizers, or ultrasonic processors.

-

Temperature and time control: critical to avoid phase separation and maintain desired viscosity.

For technical consultation, sample requests, or updated pricing of emulsifiers, emulsion-grade PVC, and related base materials, please contact our technical supply team for expert guidance.