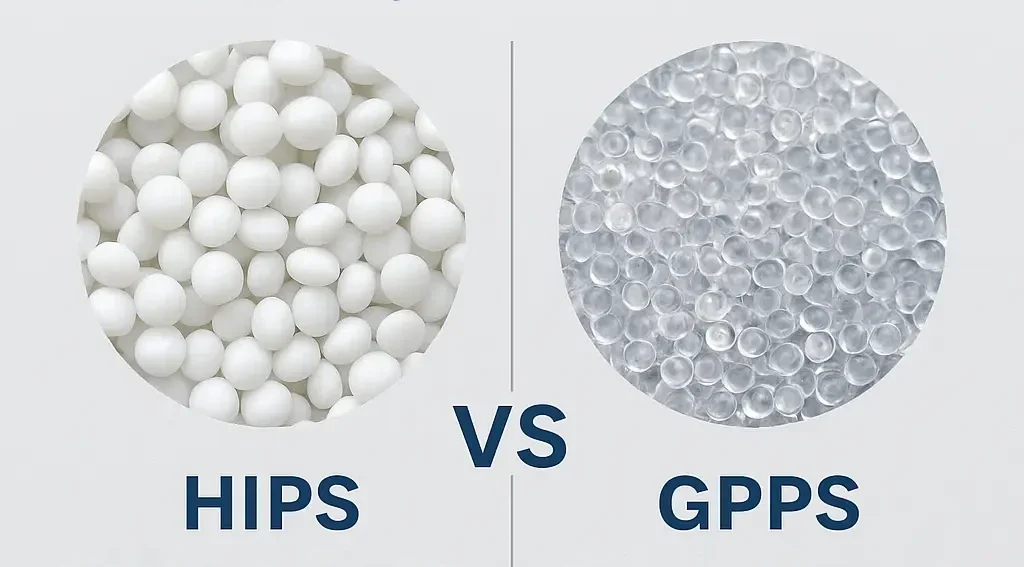

Comparison of HIPS and GPPS

Polystyrene (PS) is one of the most widely used polymer families in the plastics industry, offered in two main types: General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS). Choosing the right type between these two is crucial for manufacturers involved in injection molding and extrusion. This article provides a comprehensive comparison of their structures, properties, applications, advantages, and disadvantages.

Structural and Production Comparison of GPPS and HIPS

General Purpose Polystyrene (GPPS)

-

Chemical structure: a homopolymer of styrene monomer without additives.

-

Production process: solution or suspension polymerization of styrene.

-

Key characteristic: high purity and excellent transparency.

High Impact Polystyrene (HIPS)

-

Chemical structure: a styrene–butadiene copolymer, where rubber (polybutadiene) particles are dispersed within the polystyrene matrix.

-

Production process: suspension polymerization with a dual-phase system; butadiene is added to create a flexible phase.

-

Key characteristic: exceptionally high impact resistance.

Physical and Mechanical Properties of GPPS and HIPS

| Property | GPPS | HIPS |

|---|---|---|

| Transparency | Very high | Semi-transparent to opaque |

| Impact resistance | Low | High (up to 10× GPPS) |

| Melt Flow Index (MFI) | 3–5 g/10 min | 2–4 g/10 min |

| Service temperature | Up to ~80°C | Up to ~100°C |

| Hardness | High | Reduced due to rubber phase |

Applications of GPPS and HIPS

| GPPS Applications | HIPS Applications |

|---|---|

| Transparent molded parts such as laboratory containers | Impact-resistant household and industrial parts (refrigerator, microwave panels) |

| Food packaging (disposable containers) | Electronic housings (TV cases, computer enclosures) |

| Transparent office and consumer products | Toys, safety tools |

| Decorative items | Automotive interior components (dashboard, console) |

Advantages and Disadvantages

| Category | GPPS | HIPS |

|---|---|---|

| Advantages | Excellent transparency, lower cost, smooth surface | High impact strength, easy processing, enhanced durability |

| Disadvantages | Brittle, low impact resistance | Less transparency, higher cost |

Production Process of GPPS and HIPS

1. General Purpose Polystyrene (GPPS)

GPPS is an amorphous, transparent, and brittle polymer produced by continuous or batch polymerization of styrene monomer, typically via bulk or solution polymerization.

Main production steps:

-

Purification of styrene monomer: removing impurities such as water or peroxides.

-

Polymerization initiation: adding thermal initiators (e.g., benzoyl peroxide) under controlled pressure.

-

Polymerization growth: controlling reaction time and temperature to reach the desired molecular weight.

-

Residual monomer removal: using vacuum stripping or distillation.

-

Degassing and pelletizing: the molten polymer is extruded, cooled, and granulated.

Key GPPS properties:

-

High optical clarity

-

Excellent rigidity and moldability

-

Suitable for food containers, household goods, and electronic components

2. High Impact Polystyrene (HIPS)

HIPS is a rubber-modified copolymer, produced by blending polystyrene with polybutadiene rubber to enhance toughness. The polymer is manufactured via emulsion or modified solution polymerization to improve its impact resistance.

Main production steps:

-

Preparation of rubber solution: dissolving 5–10% polybutadiene rubber in styrene monomer.

-

Polymerization initiation: polymerizing styrene in the presence of rubber under controlled conditions.

-

Formation of rubber phase: rubber particles form spherical domains dispersed within the PS matrix.

-

Phase and particle size control: to balance transparency and impact strength.

-

Final polymerization, degassing, and pelletizing.

Key HIPS properties:

-

High impact resistance

-

Matte surface and good mechanical strength

-

Widely used in electronics, toys, packaging, and refrigeration components

Differences in Production Between GPPS and HIPS

| Production Aspect | GPPS | HIPS |

|---|---|---|

| Polymerization type | Bulk or solution polymerization | Rubber-modified polymerization |

| Additives | None | 5–10% polybutadiene rubber |

| System phases | Single-phase (homogeneous) | Dual-phase (matrix + rubber particles) |

| Final product | Transparent and brittle | Opaque and impact-resistant |

Grade Selection Guide

-

Need high transparency → choose GPPS 1540

-

Need high impact resistance → choose HIPS 1551 or HIPS 7240

-

High-speed injection molding → match MFI of the grade

-

High-temperature or harsh environments → choose heat-resistant HIPS grades

Purchasing GPPS and HIPS

The choice between General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS) depends on your specific production requirements — particularly the desired transparency, impact resistance, and processing conditions.

Common industrial grades such as GPPS 1540 and HIPS 1551 allow manufacturers to optimize product performance and control production costs effectively.

For technical consultation and up-to-date pricing of GPPS and HIPS grades, please contact our technical sales team.